Size-controllable transition metal oxide ultrafine nano-particles and rapid preparation method and application thereof

A transition metal, ultra-fine nano technology, applied in the directions of iron oxide, nanotechnology, nanotechnology, etc., can solve the problems of increasing preparation steps and consumption costs, and achieve the solution of large and uncontrollable size, good dispersibility, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A rapid preparation method for size-controllable NiO ultrafine nanoparticles, comprising the following steps:

[0054] 1) Weigh 15.5g of nickel sulfate hexahydrate and dissolve it in 35mL of deionized water to form a 1.69mol / L A solution;

[0055] 2) Weigh 5.1g of NaOH and dissolve it in 36mL of 5% NaClO to form B solution, the concentration of NaOH is 3.5mol / L;

[0056] 3) Slowly add solution B to solution A, stir at a constant speed for 90 minutes; centrifuge and wash with deionized water for several times until the pH of the supernatant is neutral, dry at 50°C, and put it in a muffle furnace Heat treatment at 300°C for 2 hours to obtain NiO nanoparticles.

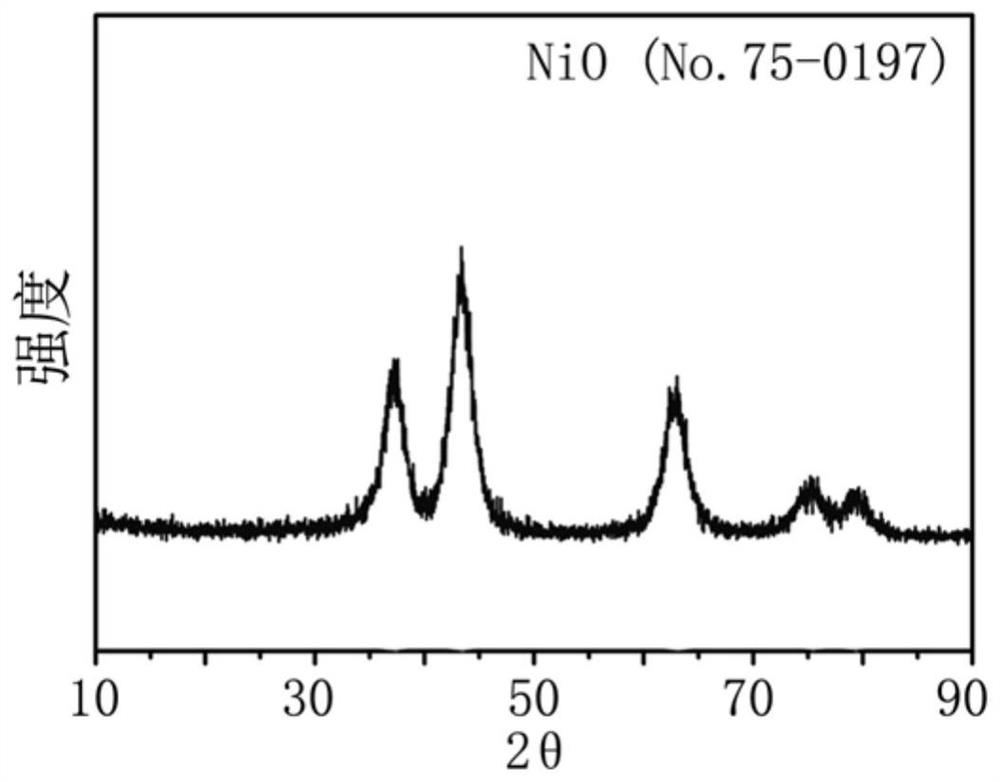

[0057] A sample of the final product was characterized by X-ray powder diffraction XRD, as figure 1 As shown, the main component of the product is NiO whose PDF card number is 75-0197.

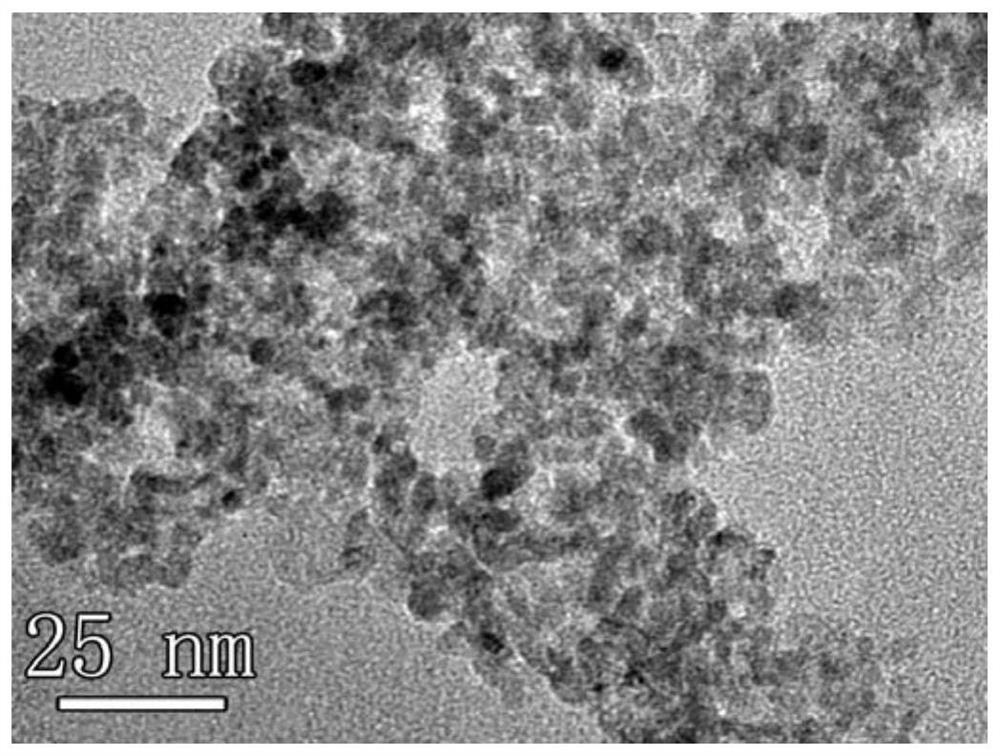

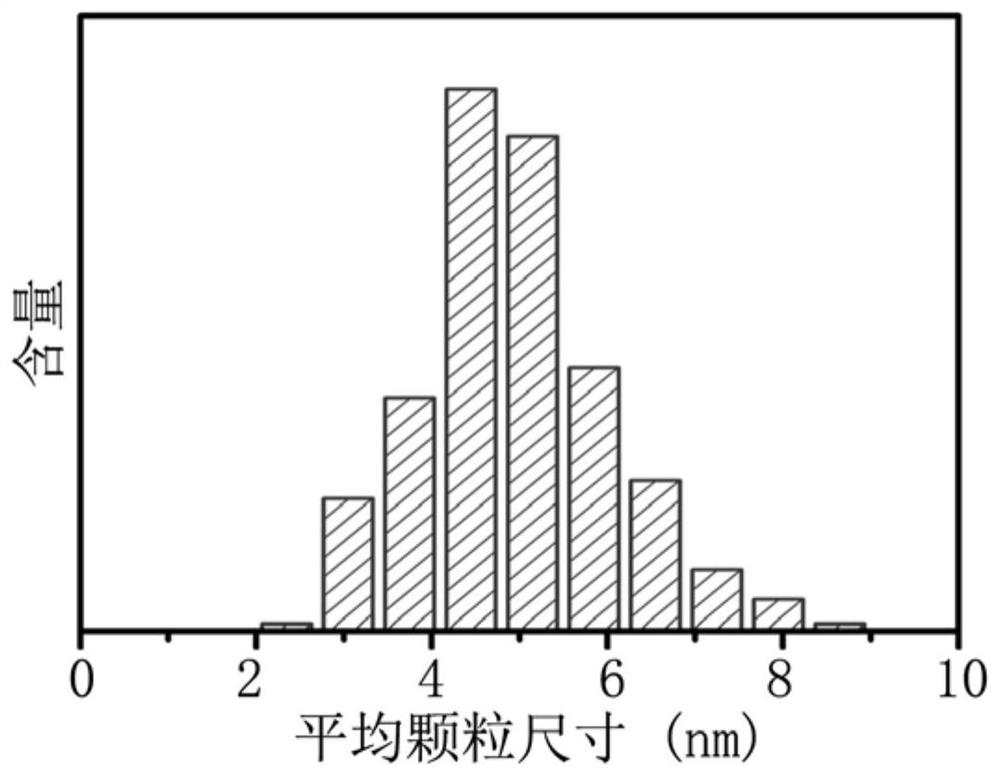

[0058] The morphology and size of the product were characterized by transmission electron microscopy (TEM), from figure 2 a...

Embodiment 2

[0067] This example observes the influence of different heat treatment temperatures on the particle size of NiO nanoparticles. The specific preparation steps adopt the technical solution in Example 1, the difference is that the heating temperature in the muffle furnace in step 3) is 400°C.

[0068] The morphology and size of the product were characterized by transmission electron microscopy (TEM), from Figure 6 It can be seen that the obtained ultrafine NiO particles are uniform in size, and the average size of the particle diameter is 10 nm.

Embodiment 3

[0070] A kind of Co 3 o 4 A rapid preparation method for ultrafine nanoparticles, comprising the following steps:

[0071] 1) Weigh 18.5g of cobalt sulfate hexahydrate and dissolve it in 35mL of deionized water to form a 2.00mol / L A solution;

[0072] 2) Weigh 7.5g of KOH and dissolve it in 35mL of 8% NaClO to form B solution, the concentration of KOH is 3.8mol / L;

[0073] 3) Slowly add solution B to solution A, stir at a constant speed for 120 minutes, centrifuge, and wash with deionized water for several times until the pH of the supernatant is neutral, dry at 50°C, and put it in a muffle furnace Heat treatment at 300°C for 2 hours to obtain black Co 3 o 4 nanoparticles.

[0074] A sample of the final product was characterized by X-ray powder diffraction XRD, as Figure 7 As shown, the product composition is Co with PDF card number 42-1467 3 o 4 Material.

[0075] The morphology and size of the product were characterized by transmission electron microscopy (TEM), fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com