Kitchen waste water treatment method and treatment device thereof

A wastewater treatment and kitchen waste technology, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as low degree of automation, polluted environment, and high organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

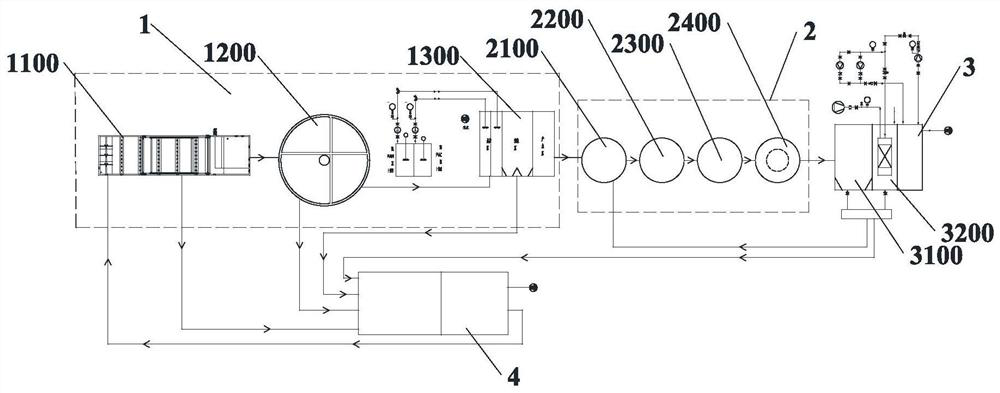

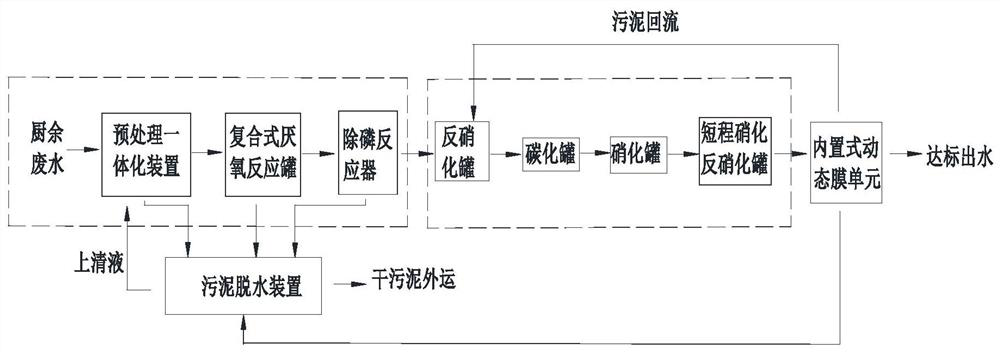

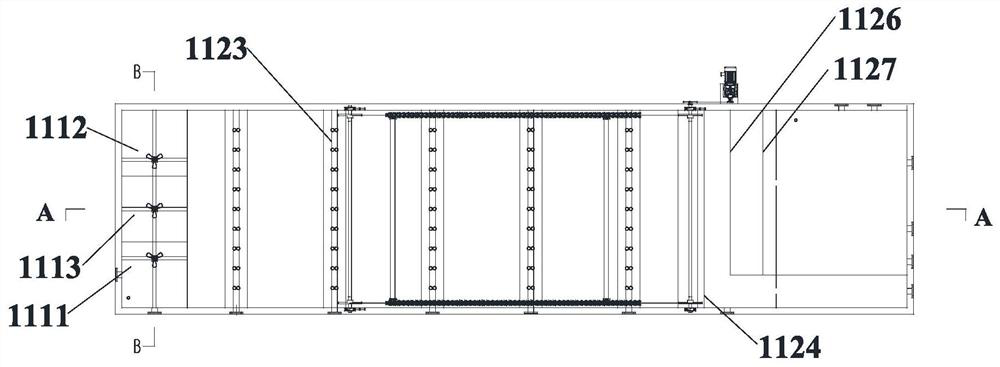

[0060] Such as Figure 1-Figure 2 As shown, a kitchen waste wastewater treatment device includes an anaerobic dephosphorization unit 1, a new high-efficiency energy-saving biochemical unit 2, a built-in dynamic membrane unit 3 and a sludge dehydration device 4, and the first output end of the anaerobic dephosphorization unit 1 is connected to the The input end of the new high-efficiency energy-saving biochemical unit 2 is connected, the second output end is connected with the sludge dewatering device 4, the new high-efficiency energy-saving biochemical unit 2 is connected with the built-in dynamic membrane unit 3, and the first of the built-in dynamic membrane unit 3 The output end is connected with the new high-efficiency energy-saving biochemical unit 2, and the second output end is connected with the sludge dewatering device 4; the anaerobic phosphorus removal unit 1 includes a pretreatment integrated device 1100 connected in sequence, a composite anaerobic Reaction tank 12...

Embodiment 2

[0070] A method for treating kitchen waste wastewater, comprising the following steps:

[0071] Add calcium oxide, sodium hydroxide, PAC, and PAM to the waste water through the pretreatment integrated device 1100 for pretreatment to obtain the supernatant, and discharge part of the sediment into the sludge dewatering device 4; the dosage of calcium oxide 5kg / t, the dosage of sodium hydroxide is 2kg / t, the dosage of PAC is 2kg / t, the dosage of PAM is 0.02kg / t, the residence time of wastewater in the pretreatment reaction zone 1110 5min, and the time of staying in the pretreatment sedimentation zone 1120 and the pretreatment water production zone 1130 is 60min respectively;

[0072] The supernatant of the above steps is anaerobically treated through the compound anaerobic tank 1200 to obtain the degraded clear liquid, and part of the sediment is discharged into the sludge dewatering device 4; wherein the residence time of the wastewater in the compound anaerobic reaction tank is...

Embodiment 3

[0078] A method for treating kitchen waste wastewater, comprising the following steps:

[0079] Add calcium oxide, sodium hydroxide, PAC, and PAM to the waste water through the pretreatment integrated device 1100 for pretreatment to obtain the supernatant, and discharge part of the sediment into the sludge dewatering device 4; the dosage of calcium oxide is 3.5kg / t, the dosage of sodium hydroxide is 1.5kg / t, the dosage of PAC is 1kg / t, the dosage of PAM is 0.01kg / t, the residence time of wastewater in the pretreatment reaction zone 1110 4min, the time of staying in the pretreatment sedimentation zone 1120 and the pretreatment water production zone 1130 is 45min respectively;

[0080] The supernatant of the above steps is anaerobically treated through the compound anaerobic tank 1200 to obtain the degraded clear liquid, and part of the sediment is discharged into the sludge dewatering device 4; wherein the residence time of the waste water in the compound anaerobic reaction tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com