Graphene-doped polypropylene-based thermoplastic cable shielding material and preparation method thereof

A technology of thermoplastic and shielding materials, which is applied in the field of semi-conductive shielding materials and preparation of graphene-doped thermoplastic cables, which can solve the problems of thermal stability, non-compliance with green development strategy, and inability to recycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

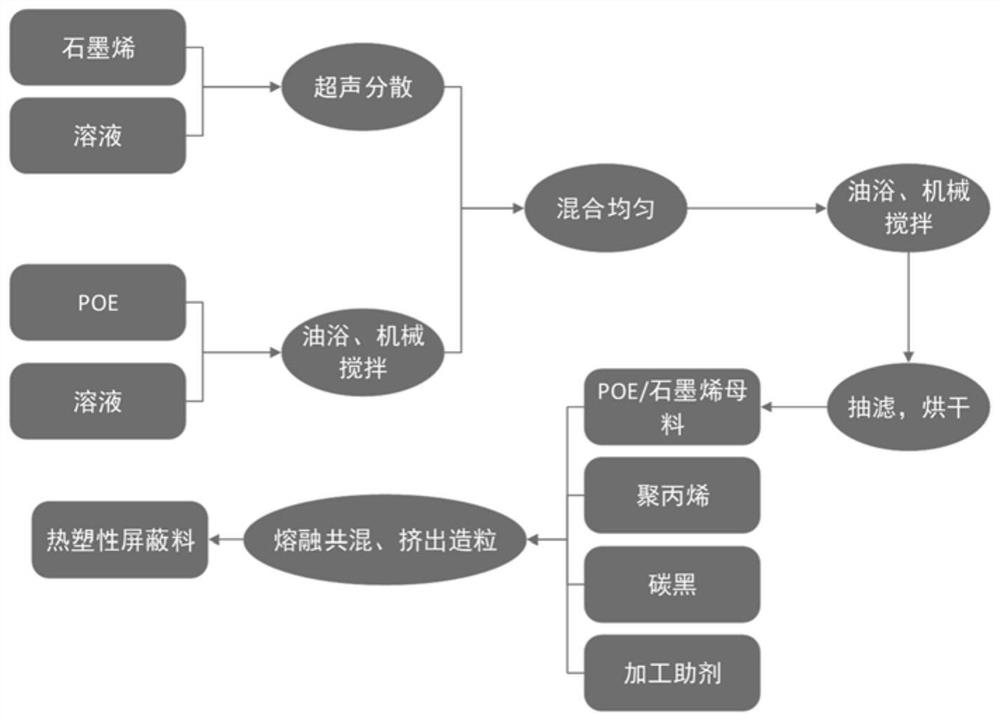

[0037] see figure 1 , the preparation method of the shielding material for the above-mentioned polypropylene-based thermoplastic cable, comprising the following steps:

[0038] 1) Add polyethylene octene co-elastomer (POE) into the solvent, control the mass ratio of POE to solvent at 1:10~30, heat the oil bath to 100~120°C, keep mechanical stirring for 1-2h, and obtain POE solution ;

[0039] 2) Add graphene powder into the solvent, the mass ratio of graphene to solvent is 1:1000-2000, ultrasonically vibrate for 10-30min, and the ultrasonic power is 150w-300w, and obtain the graphene slurry after ultrasonic dispersion;

[0040] 3) Add the graphene slurry into the POE solution, maintain an oil bath at 100-120°C, and mechanically stir for 5-7 hours to obtain a uniformly mixed POE / graphene mixture;

[0041] 4) Add the POE / graphene mixture into the Buchner funnel, vacuum filter to obtain the flocculent mixture, put the obtained mixture into a vacuum oven, treat at 40-60°C for 24...

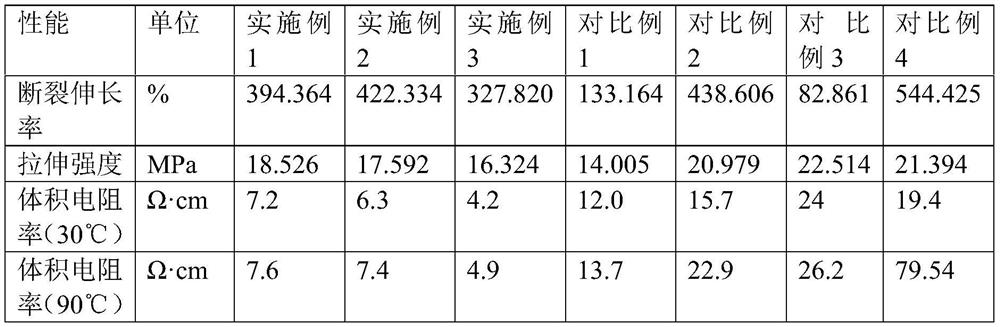

Embodiment 1

[0047] A shielding material for polypropylene-based thermoplastic cables doped with graphene, in parts by mass, comprising:

[0048] Polypropylene: 70 parts

[0049] Polyethylene octene co-elastomer (POE): 30 parts

[0050] Conductive carbon black: 14 parts

[0051] Graphene: 1 part

[0052] Coupling agent A172: 1 part

[0053] Antioxidant 300: 1.5 parts

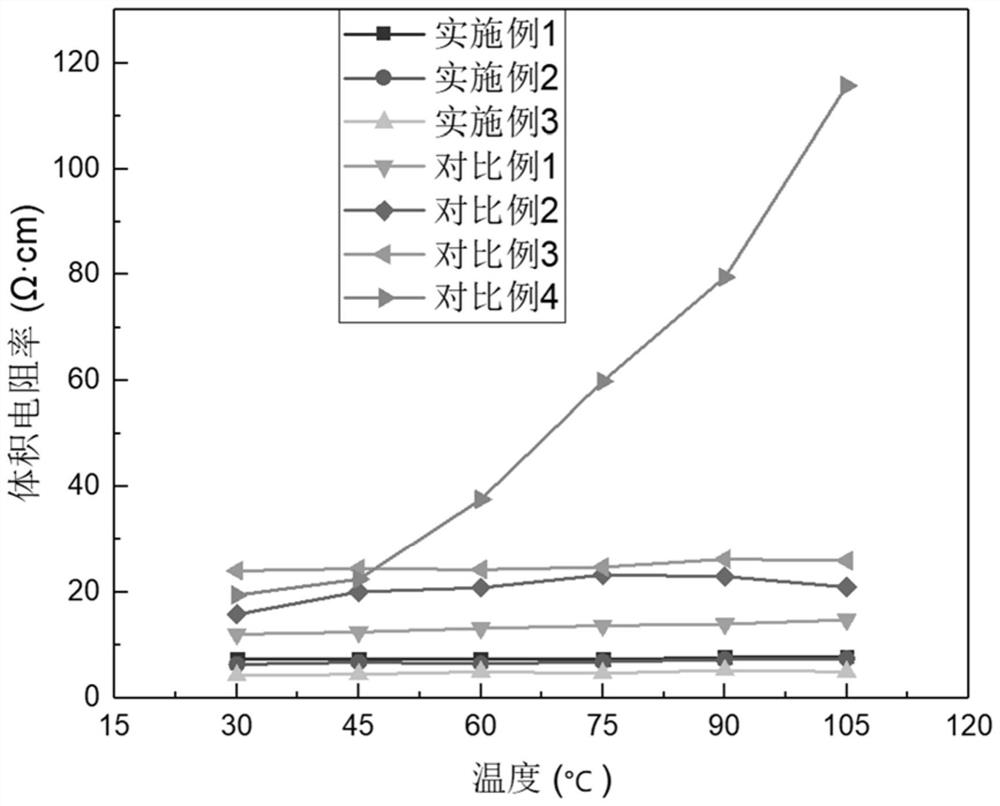

[0054] Add 30 parts of POE to 600 parts of toluene, heat the oil bath to 100°C, and mechanically stir for 1 hour to form a POE solution. Add 1 part of graphene with a layer number of 3 to 500 parts of toluene, ultrasonically disperse for 15 minutes, and ultrasonic power is 250w , to make a graphene dispersion, add the graphene dispersion to the POE solution, keep the oil bath heating at 100 ° C and mechanically stir for 6 hours to obtain a POE / graphene mixture, and obtain a flocculent POE / graphene mixture after vacuum filtration , put the mixture in a vacuum oven, and dry the solution at 50°C for 24 hours to obtain a PO...

Embodiment 2

[0056] A shielding material for polypropylene-based thermoplastic cables doped with graphene, in parts by mass, comprising:

[0057] Polypropylene: 60 parts

[0058] Polyethylene octene co-elastomer (POE): 40 parts

[0059] Conductive carbon black: 14 parts

[0060] Graphene: 1 part

[0061] Coupling agent kh550: 1 part

[0062] Antioxidant 1010: 1 part

[0063] Antioxidant 300: 0.5 parts

[0064] Add 40 parts of POE to 600 parts of xylene, heat the oil bath to 120°C, and mechanically stir for 1 hour to form a POE solution. Add 1 part of graphene to 600 parts of toluene, ultrasonically disperse for 10 minutes, and ultrasonic power is 300w to make graphite Add the graphene dispersion with 3 layers to the POE solution, keep the oil bath heating at 120°C and mechanically stir for 8 hours to obtain the elastomer / graphene mixture, and obtain the flocculent POE / graphite after vacuum filtration Graphene mixture, put the mixture in a vacuum oven, treat at 50°C for 24h, and dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com