Sphingomonas sanxanigenens and use thereof

A sphingomonas, strain technology, applied in bacteria, biological water/sewage treatment, biochemical equipment and methods, etc., can solve the problems of high cost of biological flocculants, complicated extraction steps, consumption of a large amount of solvent, etc. Remarkable technical economy, wide pH range of use environment and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example is used to illustrate Sphingomonas Sphingomonas sanxanigenes The identification method and result of HL-1, its steps include:

[0028] (1) Extraction of total bacterial genome DNA: Take 200 μL of HL-1 bacterial liquid from the strain preservation tube into LB medium, put it in a shaking table at 30°C and 200 rpm for 24 h, and extract the total DNA with a genomic DNA extraction kit. DNA.

[0029] (2) PCR amplification of bacterial 16S rDNA: Use bacterial universal primers 27F and 1492R, detect the amplified product by 1% agarose gel electrophoresis, and send it to a sequencing company for sequencing identification.

[0030] Reaction system: ddH 2 O: 20 μL

[0031] High-fidelity DNA polymerase and mixed substrate: 25 μL

[0032] Primer 1: 2 μL

[0033] Primer 2: 2 μL

[0034] Template: 1 μL

[0035] Reaction conditions: pre-denaturation at 95°C for 3 min, denaturation at 95°C for 15 s, annealing at 56°C for 15 s, extension at 72°C for 30 s / 1kb, and ext...

Embodiment 2

[0038] This example is used to illustrate Sphingomonas Sphingomonas sanxanigenes HL-1 produces the cultivation method of biological flocculant, and its steps comprise:

[0039] (1) Take 200 μL from the strain preservation tube Sphingomonas sanxanigenes Put the HL-1 bacterial liquid into the Erlenmeyer flask containing the strain activation medium, put it into a shaker at 30°C and 200 rpm for 24 h, dip a small amount of bacterial liquid with an inoculation loop and streak on the strain activation plate, and incubate at 30 Cultivate in an incubator for 48 h.

[0040] (2) Use an inoculation loop to pick a well-growing single colony on the activation plate and inoculate it into a 250 mL Erlenmeyer flask containing 50 mL of seed medium, and culture it on a shaker at 30°C and 200 rpm for 24 h.

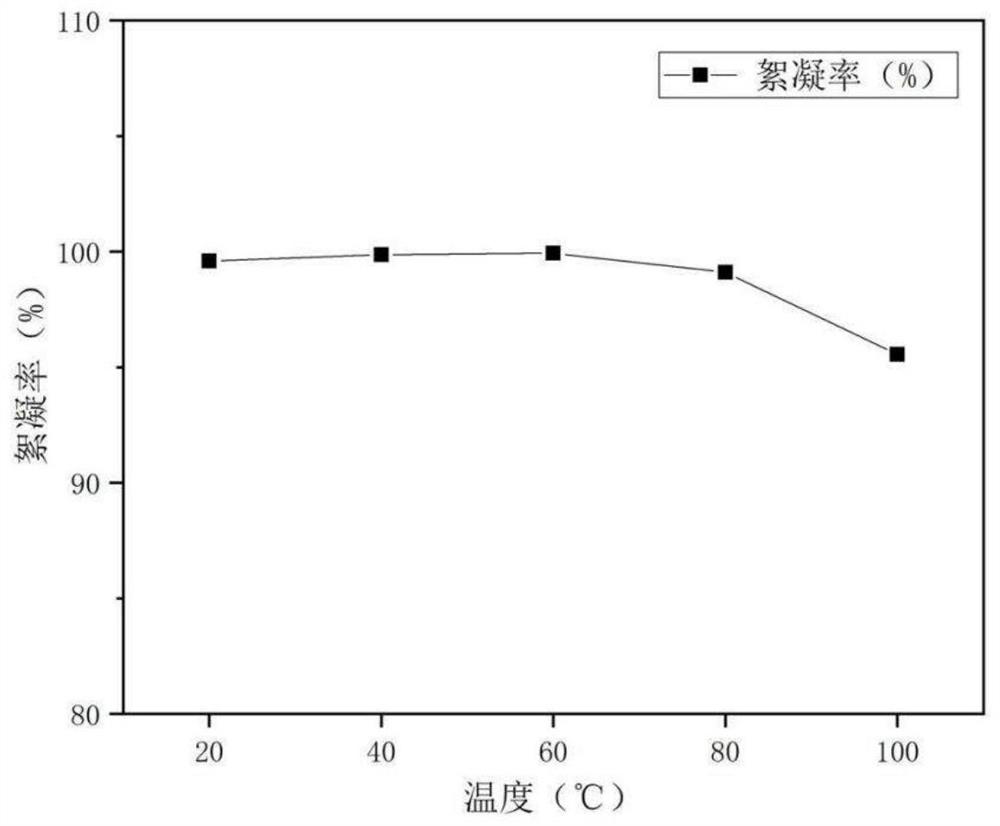

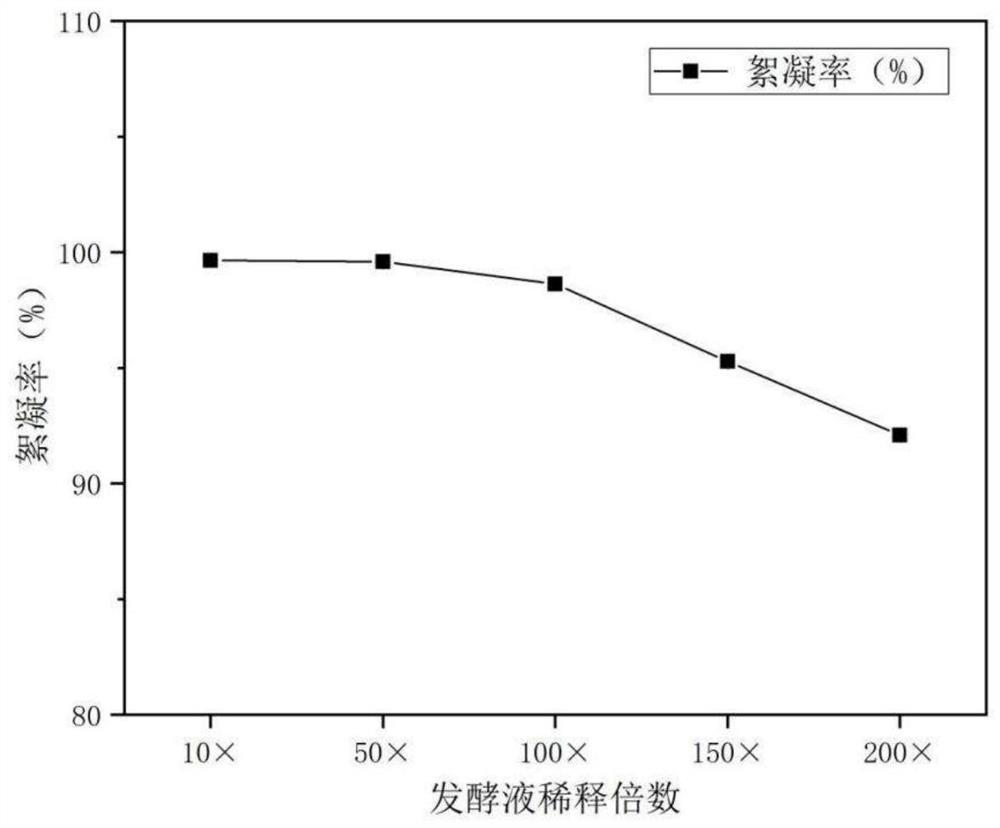

[0041] (3) The cultured seed solution was transferred into a 250 mL Erlenmeyer flask containing 50 mL of fermentation medium at an inoculation volume of 6 % (v / v), and placed in a shaker a...

Embodiment 3

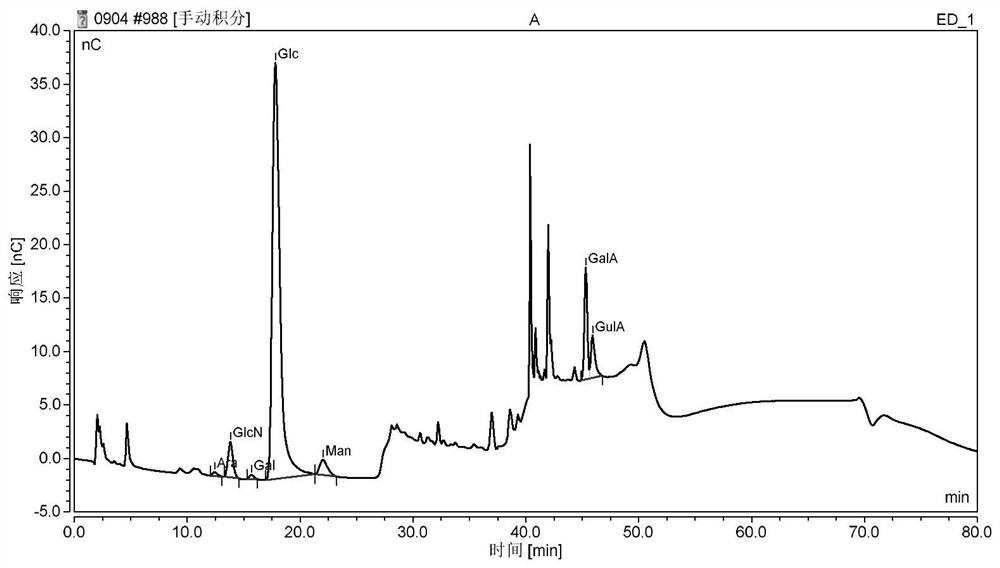

[0046] This example is used to illustrate Sphingomonas Sphingomonas sanxanigenes HL-1 produces the extraction method of extracellular polysaccharide, and its step comprises:

[0047] (1) Extraction of crude exopolysaccharide: put the fermentation broth in Example 2 in a water bath at 80°C for 20 minutes, dilute it with distilled water in equal volume, and centrifuge at 8000 r / min for 30 minutes to remove bacteria, collect the supernatant, concentrate and add 3 times the volume of 95% ethanol, mix well, put it in the refrigerator at 4°C overnight, centrifuge at 8000 r / min for 30 min to remove the supernatant, repeat several times, collect the precipitate, put it in an oven at 80°C to dry to constant weight, and obtain Crude exopolysaccharide.

[0048](2) Remove protein: Dissolve an appropriate amount of crude product in 100 mL distilled water, heat and stir until it dissolves, add 20 mL of a solution of chloroform: n-butanol = 4:1, shake for 30 min, and centrifuge at 8000 r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com