Glyphosate synthesis method for improving utilization rate of dimethyl phosphite

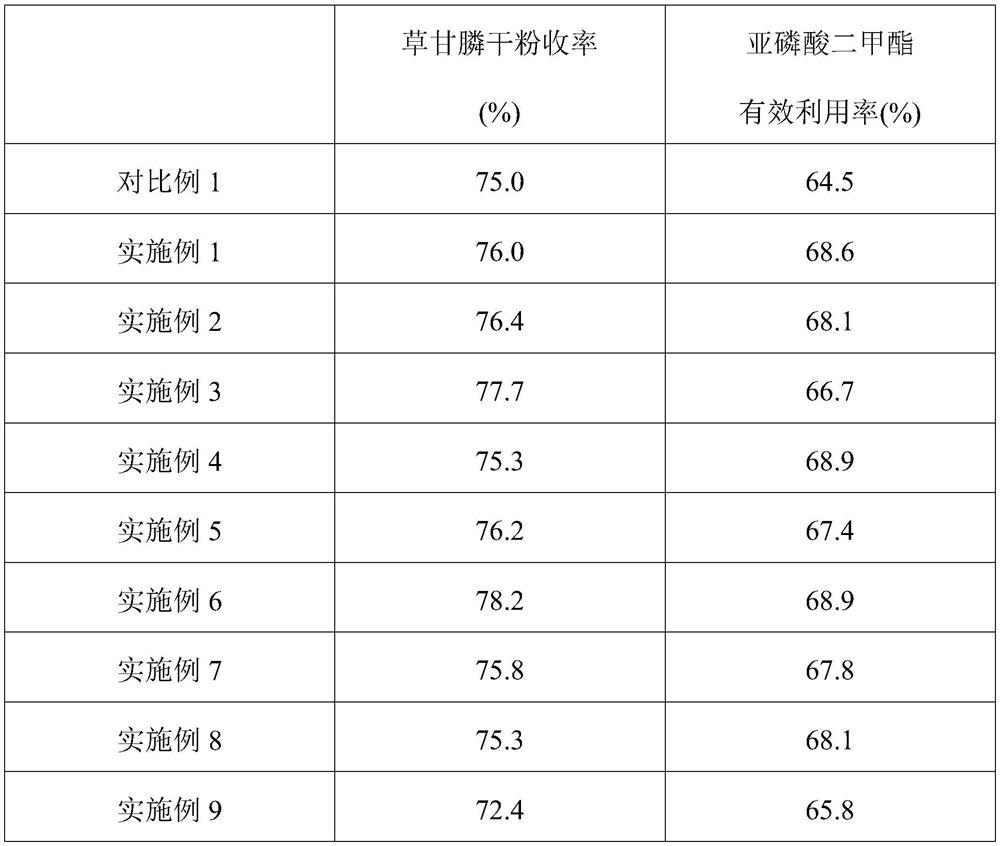

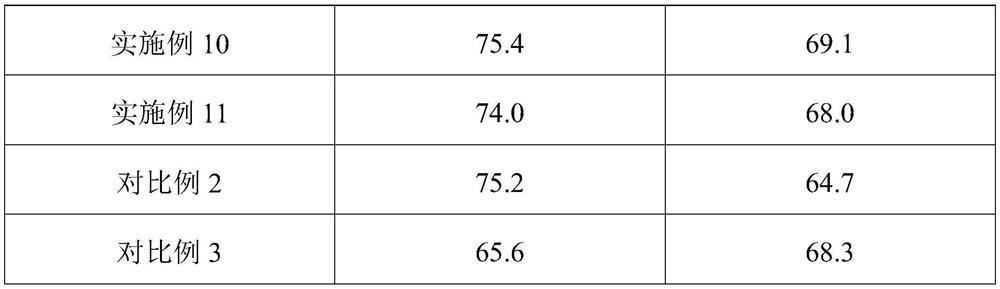

A technology for the synthesis of dimethyl phosphite, which is applied in the field of pesticide chemical industry, can solve the problems of great influence on the recovery rate of glycine, low utilization of dimethyl phosphite, and waste of glycine, etc., so as to reduce production cost, improve utilization rate, The effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

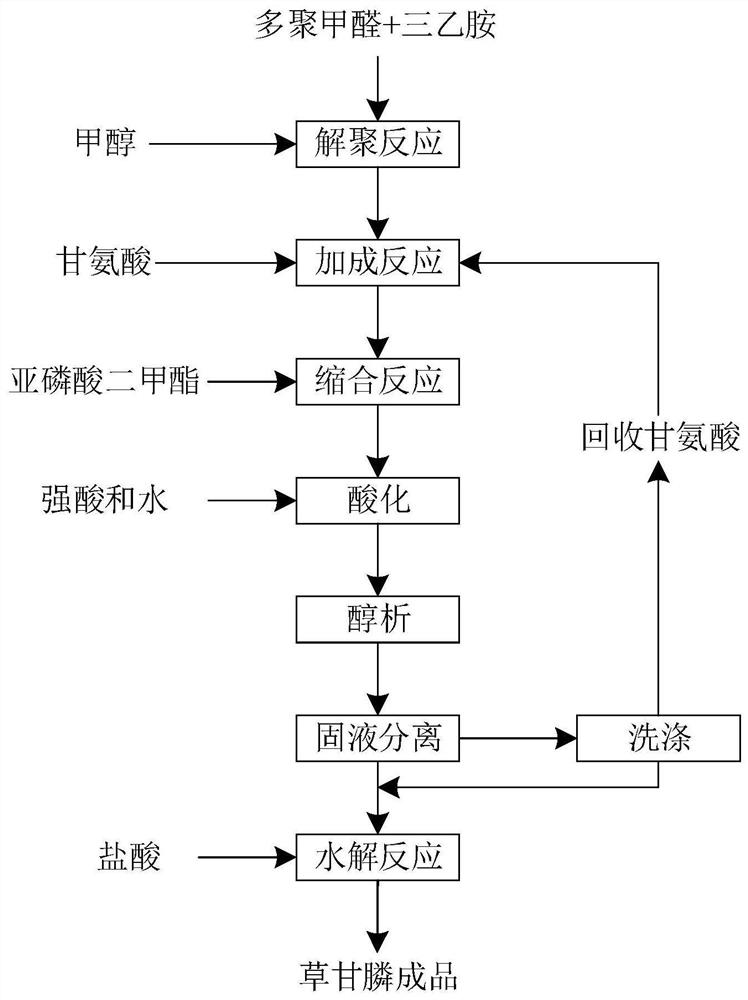

[0071] This embodiment provides a figure 1 The glyphosate synthetic method that improves the utilization rate of dimethyl phosphite shown, the glyphosate synthetic method comprises the steps:

[0072] (1) Add 38g of paraformaldehyde, 208g of methanol and 67.6g of triethylamine into a 1000mL four-necked reaction flask, raise the temperature to 47°C, stir for 30 minutes and then cool down to 37°C to complete the depolymerization reaction;

[0073] (2) Add 57.6 g of glycine to the depolymerization reaction product, control the temperature at 42° C., and stir for 60 minutes to complete the addition reaction;

[0074](3) Add 82.4 g of dimethyl phosphite to the addition reaction product, control the temperature at 52°C, and stir for 80 minutes to complete the condensation reaction;

[0075] (4) Pass 15g of hydrogen chloride gas into the product after the condensation reaction, add 18g of water, control the temperature at 40°C, stir for 60 minutes, add 100g of methanol for alcohol a...

Embodiment 2

[0078] This embodiment provides a figure 1 The glyphosate synthetic method that improves the utilization rate of dimethyl phosphite shown, the glyphosate synthetic method comprises the steps:

[0079] (1) Add 38g of paraformaldehyde, 208g of methanol and 67.6g of triethylamine into a 1000mL four-necked reaction flask, raise the temperature to 47°C, stir for 30 minutes and then cool down to 37°C to complete the depolymerization reaction;

[0080] (2) Add 49.2 g of glycine to the depolymerization reaction product, add 8 g of glycine recovered in Example 1, control the temperature at 42° C., and stir for 50 minutes to complete the addition reaction;

[0081] (3) Add 82.4 g of dimethyl phosphite to the addition reaction product, control the temperature at 52°C, and stir for 80 minutes to complete the condensation reaction;

[0082] (4) Add 27.8g of 36% hydrochloric acid to the product after the condensation reaction, control the temperature at 45°C, stir for 30 minutes, add 100g ...

Embodiment 3

[0085] This embodiment provides a figure 1 The glyphosate synthetic method that improves the utilization rate of dimethyl phosphite shown, the glyphosate synthetic method comprises the steps:

[0086] (1) Add 38g of paraformaldehyde, 208g of methanol and 68.6g of triethylamine into a 1000mL four-necked reaction flask, raise the temperature to 47°C, stir for 30 minutes and cool down to 37°C to complete the depolymerization reaction;

[0087] (2) Add 47.6 g of glycine to the depolymerization reaction product, add 5 g of glycine recovered in Example 2, control the temperature at 42° C., and stir for 60 minutes to complete the addition reaction;

[0088] (3) Add 82.4 g of dimethyl phosphite to the addition reaction product, control the temperature at 52°C, and stir for 80 minutes to complete the condensation reaction;

[0089] (4) Add 18g of 36% hydrochloric acid to the product after the condensation reaction, control the temperature at 40°C, stir for 30 minutes, add 50g of metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com