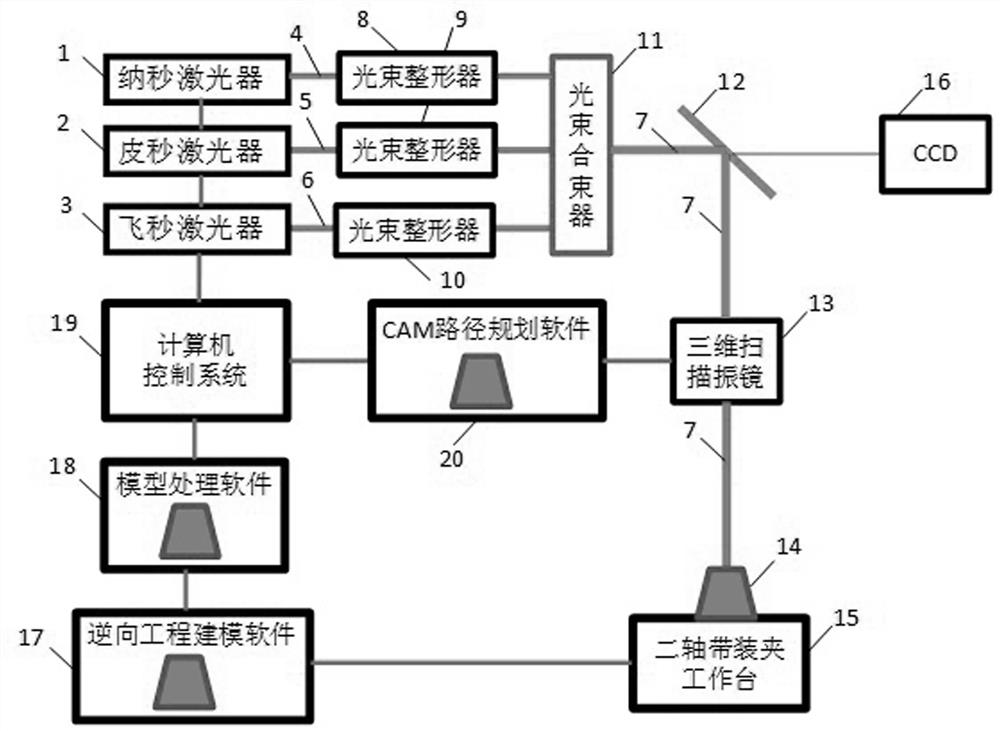

Nanosecond, picosecond and femtosecond beam combination laser parallel finishing and polishing machining method

A processing method, femtosecond technology, applied in the field of additive manufacturing, can solve problems such as low efficiency, high cost, and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Install the metal additive manufacturing parts 14 of TC4 alloy on the two-axis belt clamping workbench 15, and put the whole device in an argon inert gas sealed cabin, the oxygen and water content in the sealed cabin is ≤50ppm, the purpose It is to prevent the metal from being oxidized and polluted by the air; the digital model of the metal additive manufacturing part 14 of the TC4 alloy is established by reverse engineering modeling software, and compared with the shape and size of the three-dimensional model of the actual metal additive manufacturing part 14, through The model processing software determines the machining allowance of the metal additive manufacturing parts 14 of the TC4 alloy, and the machining allowance is determined to be about 800 μm;

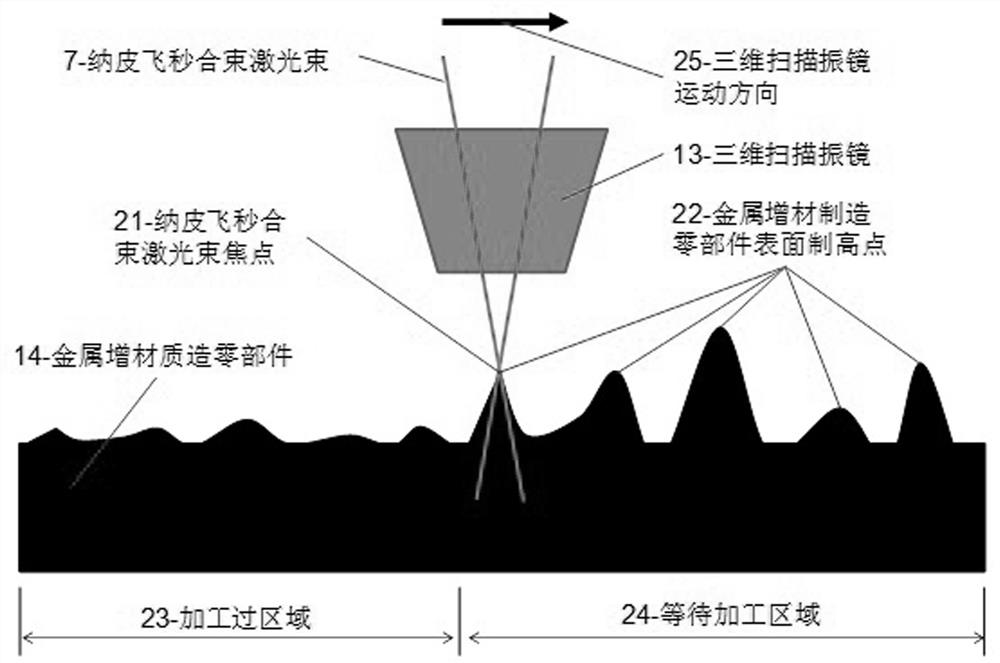

[0041] 2. Through the CAM path planning software 20, the machining allowance path of the metal additive manufacturing parts 14 of the TC4 alloy is transmitted to the three-dimensional scanning galvanometer 13 and t...

Embodiment 2

[0047] The TC4 alloy in embodiment 1 is replaced by nickel-based superalloy, and the method is the same as in embodiment 1. The scanning speed of the three-dimensional scanning galvanometer 13 is 120m / min; the high energy density of the nanopicosecond combined laser beam 7 is used to combine the principle of evaporation and melting of the metal, and the focus of the nanopicosecond combined laser beam 7 Irradiate the metal additive manufacturing parts of nickel-based superalloy 14 to the commanding heights of the surface of the machining allowance, so that the metal at the commanding heights of the surface evaporates and melts. After the first layer is completed, the second layer is cycled, and so on for the twelfth cycle. Layer, realized the metal additive manufacturing parts of nickel-based superalloys, the subsequent processing thickness (depth) ≈ 50 μm, and the processing allowance was determined to be about 600 μm; the processing efficiency ≈ 10cm 2 / min, surface roughnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com