Chitosan-chlorin e6 antibacterial agent and preparation method thereof

A technology of chlorin and chitosan, which is applied in botany equipment and methods, antibacterial drugs, biocides, etc., can solve the problems of no research report and poor effect, achieve good application prospects, and the purification method is simple , good inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

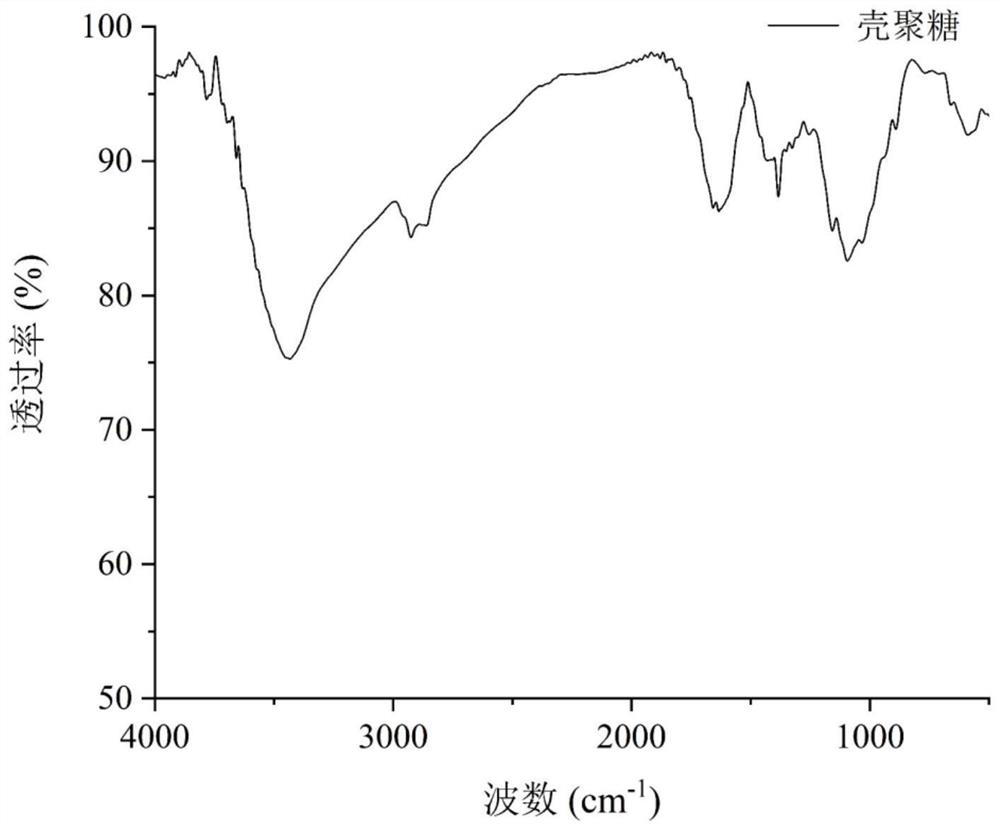

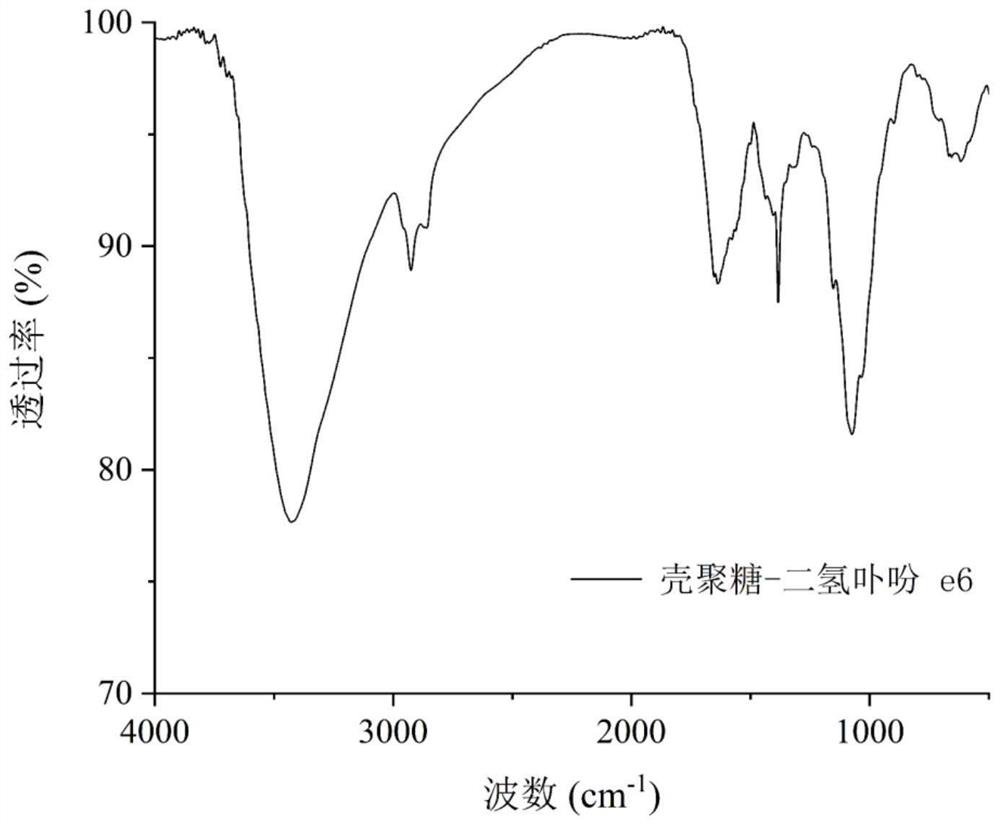

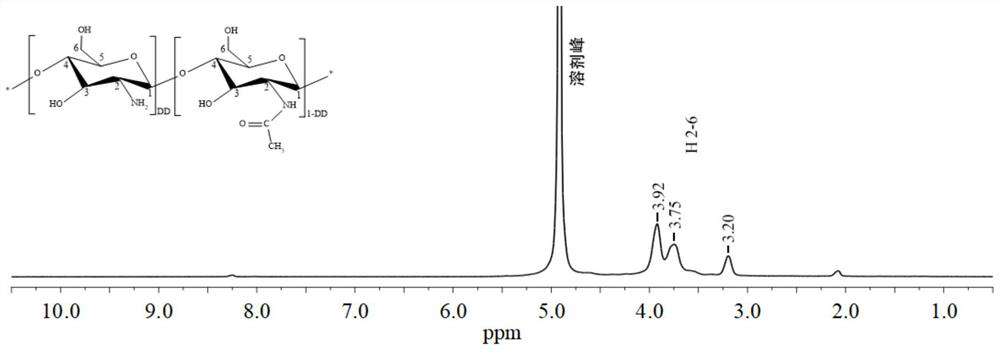

[0046] The preparation method of chitosan-chlorin e6 comprises the following steps:

[0047] Chitosan-chlorin e6 was synthesized by EDC / NHS method.

[0048] First, dissolve chitosan (120mg) in 100mL acetic acid solution (1%, v / v), adjust its pH to about 6.0 with 1mol / L sodium hydroxide solution, add ultrapure water to 120mL to obtain 1mg / mL chitosan solution.

[0049]Then, EDC (55 mg) and NHS (66 mg) were dissolved in 5 mL of MES buffer (MES: 0.05 mol / L; pH was adjusted to 6.0 with 1 mol / L sodium hydroxide solution), and chlorin e6 (56 mg) Dissolve in 5 mL dimethyl sulfoxide respectively, and add the obtained chlorin e6 solution into the MES solution of EDC / NHS, and stir for 4 hours at room temperature in the dark, at a speed of 400 rpm.

[0050] The mixed solution obtained after the stirring is added dropwise to the above chitosan solution, stirred at room temperature for 24 hours in the dark, and the obtained mixed solution is dialyzed against ultrapure water for 3 days, a...

Embodiment 2

[0056] First, chitosan (120 mg) was dissolved in 100 mL of acetic acid solution (1%, v / v), and ultrapure water was added to 120 mL to obtain a 1 mg / mL chitosan solution.

[0057] Then, chlorin e6 (56 mg) was dissolved in 5 mL of dimethyl sulfoxide, respectively, EDC (55 mg) and NHS (66 mg) were added, and stirred at room temperature for 4 h in the dark at 400 rpm.

[0058] The mixed solution obtained after the stirring was finished was added dropwise to the above-mentioned chitosan solution, and stirred at room temperature for 24 hours in the dark. The product was purified by centrifugation at 14000rpm for 20min, but the target product could not be obtained because the product was soluble in the system.

Embodiment 3

[0060] First, chitosan (120 mg) was dissolved in 100 mL of acetic acid solution (1%, v / v), and ultrapure water was added to 120 mL to obtain a 1 mg / mL chitosan solution.

[0061] Then, chlorin e6 (56 mg) was dissolved in 5 mL of dimethyl sulfoxide, respectively, EDC (55 mg) and NHS (66 mg) were added, and stirred at room temperature for 4 h in the dark at 400 rpm.

[0062] The mixed solution obtained after the stirring was finished was added dropwise to the above-mentioned chitosan solution, and stirred at room temperature for 24 hours in the dark. The acetone of the three-fold reaction system was added to precipitate the product, and then the product was purified by centrifugation at 14000 rpm for 20 min. However, after adding acetone, the volume of the system is too large, and multiple centrifuge tubes are needed for centrifugation, and the product loss is relatively large during the mixing process, resulting in a low product yield of only about 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com