Preparation method and application of Cu-MOF catalyst in acetylene hydrochlorination reaction

A technology of acetylene hydrochlorination and catalyst, which is applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc. It can solve the problem of poor conversion rate of acetylene and poor catalyst stability, etc. problems, to achieve huge energy and economic benefits, good stability, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

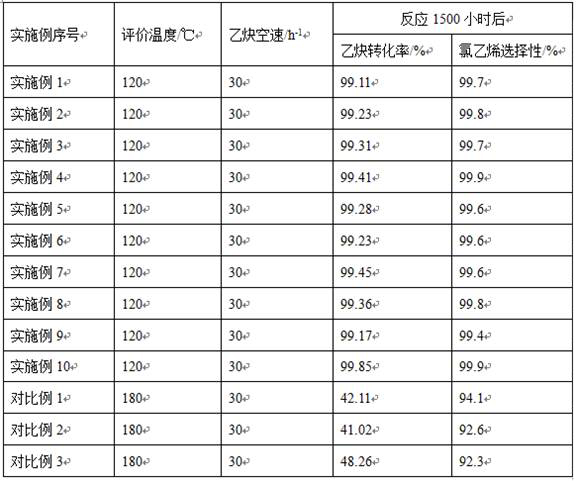

Examples

Embodiment 1

[0039] (1) Synthesis of UIO-67: 90mg 4,4'-biphenyl dicarboxylic acid, 67mg ZrCl 4 Add 50 mL of polytetrafluoroethylene (PPL) liner, then add 15 mL of N,N-dimethylformamide (DMF) and 3 mL of acetic acid. After ultrasonic dissolution, the PPL lining was placed in a stainless steel reaction vessel, sealed and heated to 120 °C, reacted for 24 h, and cooled naturally to room temperature. The resulting precipitate was separated by centrifugation, washed with DMF several times and solvent exchanged with acetone several times, and dried at 120 °C to obtain the UIO-67 material.

[0040] (2) Preparation of catalyst Cu-UIO-67: Take 20 g of UIO-67 purified in step (1) and put it into a container. Then add 1.53g of Cu(BF 4 ) 2 Impregnated with 10ml of acetonitrile, stirred for 2 hours, centrifuged, removed the supernatant, dried in vacuum at 120°C for 10 hours, and then carried out glow discharge treatment. Use a vacuum pump with a power of 500 W to keep the system in a vacuum state, an...

Embodiment 2

[0043] (1) Same as embodiment 1.

[0044] (2) Preparation of catalyst Cu-UIO-67: Take 20 g of UIO-67 in step (1) and put it into a container. Then add 4.76g of Cu(BF 4 ) 2 Impregnated with 15ml of acetonitrile, stirred for 2 hours, centrifuged, removed the supernatant, dried in vacuum at 140°C for 10 hours, and then carried out glow discharge treatment. Use a vacuum pump with a power of 500 W to keep the system in a vacuum state, and adjust the air flow to make the plasma The pressure of the body chamber was kept at 100 Pa, and the plasma treatment intensity was adjusted by adjusting the discharge voltage value, the applied voltage was 100V, and the treatment time was 1.5h. A Cu-UIO-67 catalyst with a Cu(II) loading of 6.42wt% can be obtained.

[0045] (3) After testing, this catalyst is applied to the hydrochlorination of acetylene in a fixed-bed reactor. The reaction conditions are: temperature 120°C, reaction pressure 0.01MPa, n(HCl):n(C 2 h 2 )=1:1, acetylene space ve...

Embodiment 3

[0047] (1) Same as embodiment 1.

[0048] (2) Preparation of catalyst Cu-UIO-67: Take 20 g of UIO-67 in step (1) and put it into a container. Then add 3.45g CuCl with a concentration of 45wt% 2 THF solution, stirred for 2 hours, centrifuged, removed the supernatant, vacuum dried at 160°C for 10 hours, and then subjected to glow discharge treatment, using a vacuum pump with a power of 500 W to keep the system in a vacuum state, and adjusting the air flow to make the plasma The pressure of the chamber was kept at 100 Pa, and the plasma treatment intensity was adjusted by adjusting the discharge voltage value. The applied voltage was 120V, and the treatment time was 1.5h. A Cu-UIO-67 catalyst with a Cu(II) loading of 3.70 wt% can be obtained.

[0049] (3) After testing, this catalyst is applied to the hydrochlorination of acetylene in a fixed-bed reactor. The reaction conditions are: temperature 120°C, reaction pressure 0.01MPa, n(HCl):n(C 2 h 2 )=1:1, acetylene space velocit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com