Preparation method of spherical geopolymer with high aperture ratio and hierarchical pore structure

A geopolymer, multi-level pore technology, applied in ceramic products, other household appliances, cement production, etc., can solve the problem of small average particle size of microspheres, difficult to prepare geopolymers with high open porosity, low porosity and other problems, to achieve the effect of simple implementation, wide application prospects, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

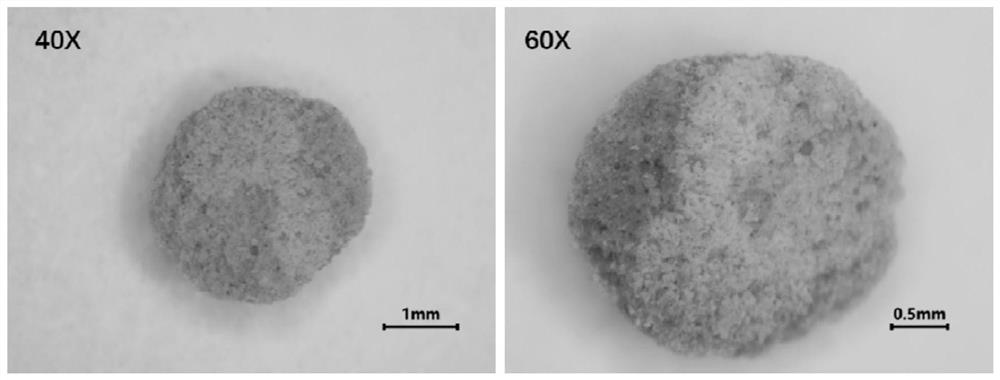

[0039] Specific embodiment one: the preparation method of a spherical geopolymer with high porosity and hierarchical pore structure according to the present embodiment is carried out according to the following steps:

[0040] Step 1: Slurry preparation: Add aluminosilicate mineral powder to the alkali excitation solution, stir and mix to form a uniform slurry, then add a surfactant, stir until evenly mixed, then add a foaming agent and continue to stir evenly to obtain Geopolymer slurry; the alkali excitation solution is formed by mixing an alkali solution and a silicate solution; wherein the alkali solution is potassium hydroxide solution or sodium hydroxide solution, and the silicate solution is potassium silicate solution , sodium hydroxide solution or lithium hydroxide solution, the mass ratio of alkali solution and silicate solution in the alkali excitation solution is 1: (1 ~ 1.5), the concentration of the alkali solution is 8mol / L ~ 15mol / L , the mass concentration of t...

specific Embodiment approach 2

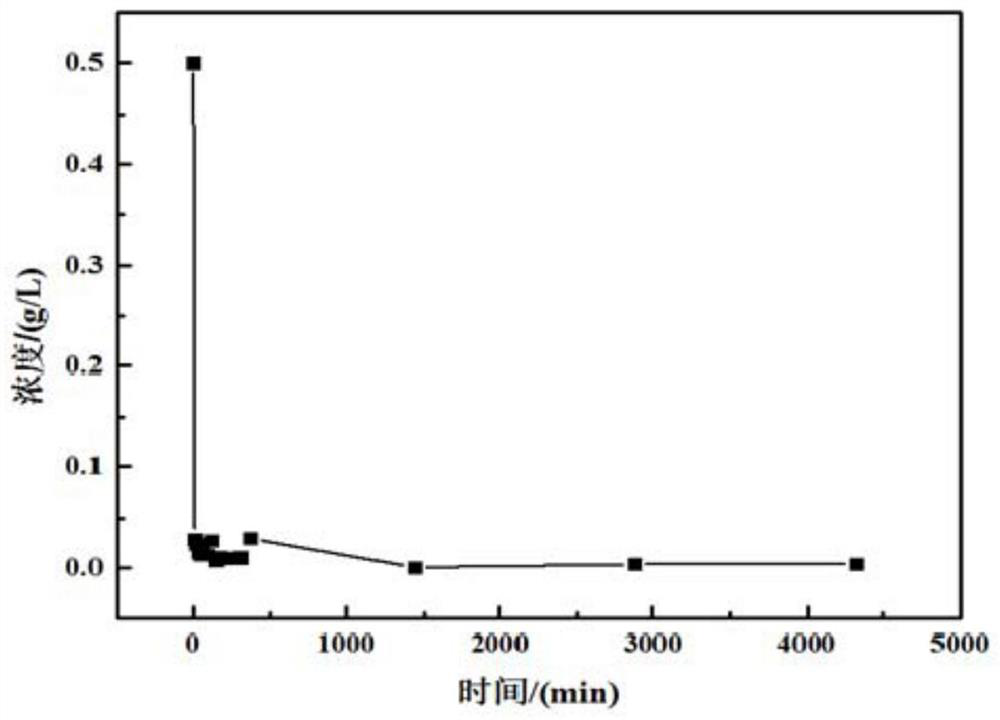

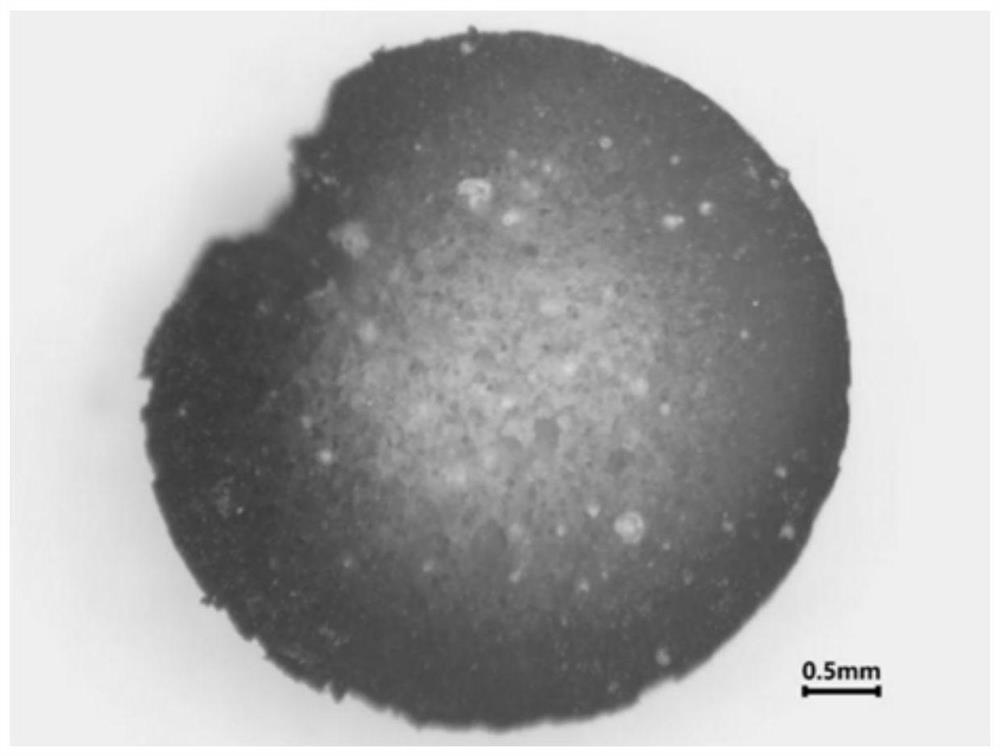

[0044] Specific embodiment 2: Put the spherical geopolymer of specific embodiment 1 after absorbing the dye in a vacuum sintering furnace, heat at 400-500°C for 3h-4h, and carry out the spherical geopolymer of specific embodiment 1 Recycle.

[0045] The spherical geopolymer of Embodiment 1 can be recycled more than 10 times, and the removal efficiency of dyes after recycling can still be greater than 90%. At the same time, due to the improved process, the spherical geopolymer has a multi-level pore structure with high open porosity, and has more excellent adsorption performance.

Embodiment 1

[0046] Embodiment 1: a kind of preparation method of the spherical geopolymer of high porosity rate hierarchical pore structure is carried out according to the following steps:

[0047] Step 1: Slurry preparation: first add aluminosilicate mineral powder to the alkali excitation solution, stir and mix at 600rpm for 40min to form a uniform slurry, then add sodium lauryl sulfate, stir at 800rpm until mixed for 2min, then add The hydrogen peroxide solution with a mass fraction of 3% was continuously stirred at 800 rpm for 5 min to obtain a geopolymer slurry; the alkali excitation solution was composed of a 13mol / L sodium hydroxide solution and a 40% sodium silicate The solution is mixed at 300rpm at a mass ratio of 1:1.25, wherein the modulus of the sodium silicate solution is 2.7, and the aluminosilicate mineral powder is a mixture of metakaolin and slag at a mass ratio of 3:7 , the mass ratio of the aluminosilicate mineral powder to the alkali excitation solution is comprehensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com