Wear-resistant self-repairing polyurethane composite coating agent based on shape memory and preparation method thereof

A self-healing, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that self-healing cannot be achieved, cracks cannot be in close contact, and it is difficult to achieve intermolecular interaction, so as to promote self-healing efficiency and range of raw materials. Wide selection of effects with high self-healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

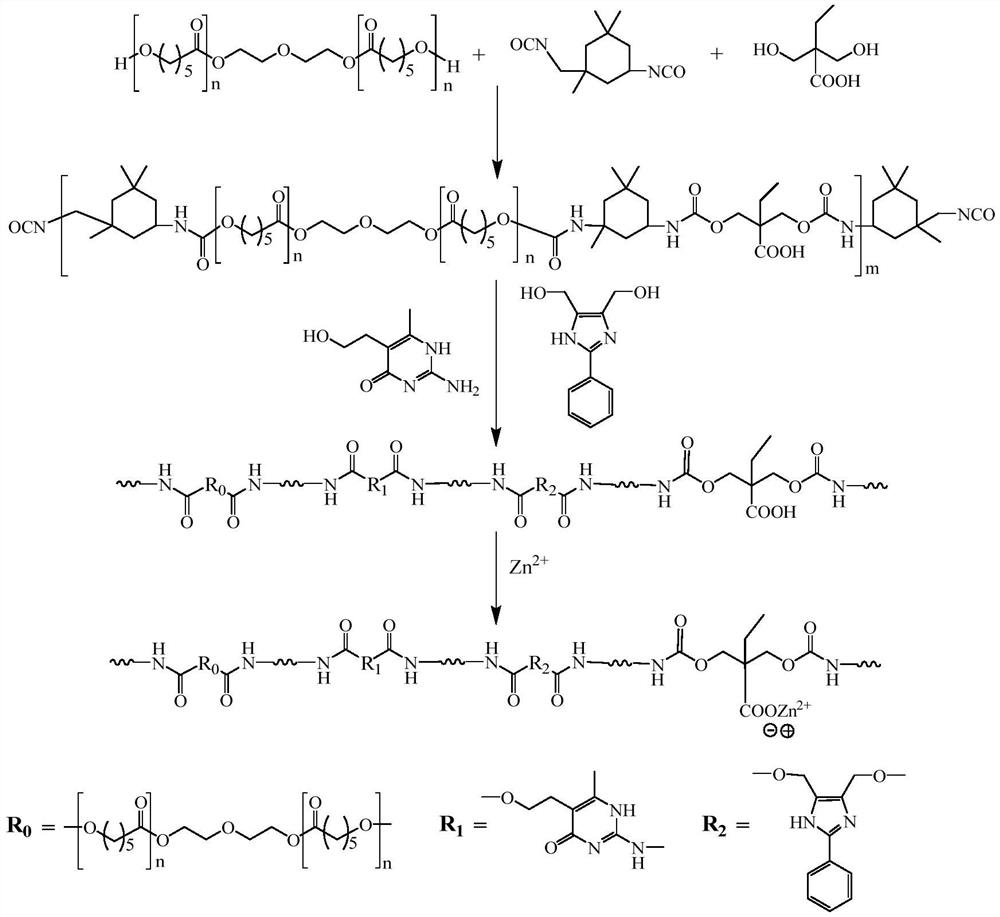

[0029] The invention discloses a preparation method of a wear-resistant self-repairing polyurethane composite coating agent based on shape memory. The process steps are as follows:

[0030] (1) Dry 10-70 parts of polyester diol and 5-20 parts of hydrophilic monomer in a vacuum oven at a temperature of 100-120° C. for 1-4 hours to remove moisture therein. Add polyester diol and hydrophilic monomer into a three-necked flask equipped with a stirrer.

[0031] (2) Add 30 to 160 parts of diisocyanate to the three-necked flask in step (1), heat and stir in a water bath in the presence of a catalyst, set the water bath temperature of the reaction system to 70 to 90°C, and stir for 2 to 3 hours.

[0032] (3) The temperature of the water bath is reduced to 50-70° C., and 15-60 parts of monomers capable of forming quadruple hydrogen bonds and 15-60 parts of monomers containing metal coordination bond structural units are added to the reaction solution obtained in step (2). Ligand post-r...

Embodiment 1

[0048] First, take 10 parts of polycarbonate diol and 5 parts of 2,2-dimethylolbutyric acid, put them in a vacuum drying oven, and dry them under vacuum at 120° C. for 2 hours to remove the moisture therein. Add the dried polycarbonate diol and 2,2-dimethylol butyric acid into a three-necked flask equipped with a stirrer. Then add 30 parts of isophorone diisocyanate into the three-necked flask, heat and stir in a water bath in the presence of dibutyltin dilaurate, set the temperature of the water bath in the reaction system to 70°C, and stir at a speed of 300r / min for 2h. Next, lower the temperature of the water bath to 50°C, add 15 parts of 5-(2-hydroxyethyl)-6-methyl-2-aminouracil and 15 parts of 2,6-pyridinedicarboxylic acid, at 300r / min Stir at high speed for 1h. Next, after the temperature of the water bath was lowered to 40° C., 5 parts of terbium trifluoromethanesulfonate were added dropwise, and stirring was continued for 40 min at a speed of 300 r / min. Finally, lowe...

Embodiment 2

[0051] First, take 35 parts of polyethylene adipate diol and 20 parts of 2,2-dimethylolbutyric acid, put them in a vacuum drying oven, and dry them under vacuum at 100° C. for 1 hour to remove the moisture therein. Add the dried polyethylene adipate diol and 2,2-dimethylol butyric acid into a three-necked flask equipped with a stirrer. Then add 65 parts of hexamethylene diisocyanate into the three-necked flask, heat and stir in a water bath in the presence of stannous octoate, set the temperature of the water bath in the reaction system to 75°C, and stir at a speed of 400r / min for 3h. Next, lower the temperature of the water bath to 55°C, add 35 parts of 2-ureido-4-1[H]-pyrimidinone and 28 parts of 2,6-diaminopyridine, and stir at 400 r / min for 2 hours. Next, after the temperature of the water bath was lowered to 40° C., 20 parts of ferric chloride was added dropwise, and stirring was continued for 50 minutes at a speed of 400 r / min. Finally, lower the temperature of the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com