Organic fertilizer fermentation microbial agent and preparation process

A fermentation agent and preparation technology, which is applied to the treatment of biological organic parts, bacteria, fungi, etc., can solve the problems of reduced activity of bacteria, shortening the time of fermentation and maturity, and reducing the number of turning times, so as to increase the number of bacteria Index, increase availability, increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

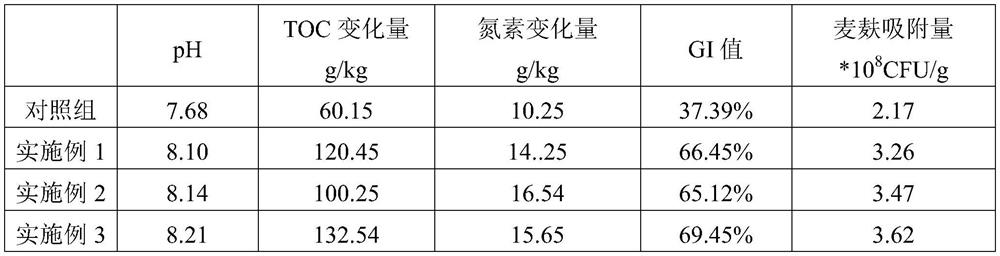

Embodiment 1

[0036] S1: Test-tube culture: take the peeled potatoes and cut them into small pieces, boil them, filter the juice, add glucose and sterilize at 110-120°C for 30 minutes to obtain a standby solution 1; take beef extract, peptone, and sodium chloride to mix and dissolve and adjust the pH to 7.2-7.5, after sterilizing at a temperature of 120-125 ℃ for 30 minutes, the second liquid is obtained; take beef extract, peptone, yeast extract, diammonium hydrogen citrate, glucose, Tween, sodium acetate, dipotassium hydrogen phosphate, magnesium sulfate, Manganese sulfate, dissolve in water, adjust pH to 6.2-6.5, pack into laboratory anaerobic bottles, and sterilize at 120-125°C for 20 minutes to obtain standby solution III;

[0037] S2: Shake flask culture: Saccharomyces cerevisiae, Bacillus terpenoids, Aspergillus oryzae, Aspergillus niger, Staphylococcus thermophilus, Bacillus amyloliquefaciens, Bacillus subtilis, and Bacillus licheniformis are separately connected to the slanted strai...

Embodiment 2

[0042] S1: Test-tube culture: take the peeled potatoes and cut them into small pieces, boil them, filter the juice, add glucose and sterilize at 110-120°C for 30 minutes to obtain a standby solution 1; take beef extract, peptone, and sodium chloride to mix and dissolve and adjust the pH to 7.2-7.5, after sterilizing at a temperature of 120-125 ℃ for 30 minutes, the second liquid is obtained; after taking beef extract, peptone, yeast extract, diammonium hydrogen citrate, glucose, Tween, sodium acetate, and dipotassium hydrogen phosphate, add water to dissolve, Adjust the pH value to 6.2-6.5, pack into laboratory anaerobic bottles, and sterilize at 120-125℃ for 20 minutes to obtain the standby solution III;

[0043] S2: Shake flask culture: Saccharomyces cerevisiae, Bacillus terpenoids, Aspergillus oryzae, Aspergillus niger, Staphylococcus thermophilus, Bacillus subtilis, and Bacillus licheniformis were separately inserted into the standby solution 1 from the slanted strains of t...

Embodiment 3

[0048] S1: Test-tube culture: take the peeled potatoes and cut them into small pieces, boil them, filter the juice, add glucose and sterilize at 110-120°C for 30 minutes to obtain a standby solution 1; take beef extract, peptone, and sodium chloride to mix and dissolve and adjust the pH to 7.2-7.5, after sterilizing at a temperature of 120-125 ℃ for 30 minutes, the second liquid is obtained; after taking beef extract, peptone, yeast extract, diammonium hydrogen citrate, glucose, Tween, sodium acetate, and dipotassium hydrogen phosphate, add water to dissolve, Adjust the pH value to 6.2-6.5, pack into laboratory anaerobic bottles, and sterilize at 120-125℃ for 20 minutes to obtain the standby solution III;

[0049] S2: Shake flask culture: Saccharomyces cerevisiae, Bacillus terpenoids, Aspergillus oryzae, Aspergillus niger, Staphylococcus thermophilus, Bacillus subtilis, and Bacillus licheniformis were separately inserted into the standby solution 1 from the slanted strains of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com