Preparation method of chondroitin sulfate

A technology of chondroitin sulfate and cartilage, applied in the biological field, can solve problems such as difficult control of process parameters, long enzymatic hydrolysis time, incomplete enzymatic hydrolysis, etc., to reduce production costs and sewage treatment costs, simple and easy to obtain, and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

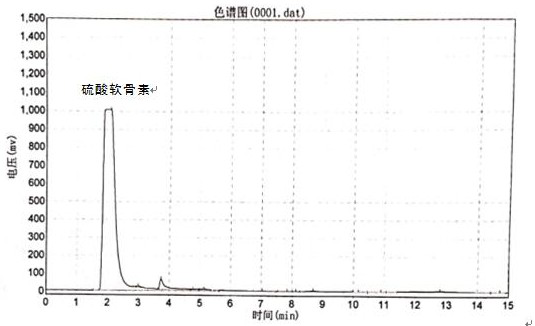

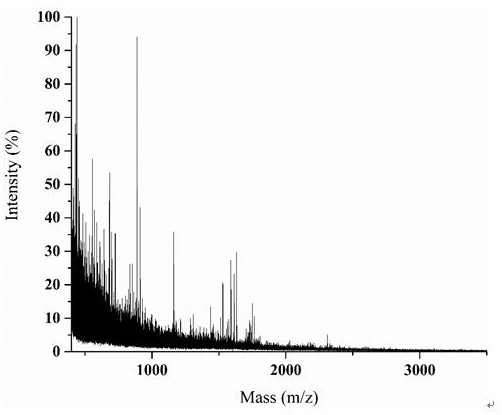

Image

Examples

Embodiment 1

[0042] Weigh 500 g of cartilage and 500 g of trachea, and wash them twice with drinking water. Put it into a cooking pot, add distilled water to immerse, heat up to 100°C, and cook for 2 hours. After cooling down to 45°C, a small amount of sodium hydroxide was added to adjust the pH of the feed solution to 8.50.

[0043] Add 35 g of porcine pancreas and 5 g of lipase to the cooking liquid, and slowly stir with a stirring paddle, keep the temperature at 45-50°C, and react for 4 h.

[0044] In the above feed solution, a mixed enzyme containing neutral protease and collagenase was added according to the ratio of 0.20% of the raw material mass (the mass ratio of the two in the mixed enzyme was 2:1), and the temperature was maintained at 45 ° C for 2.5 h. (The pH is stable after the primary enzymatic hydrolysis, which is suitable for the secondary enzymatic hydrolysis reaction, and there is no need to add additional acid and alkali to adjust the pH). The filter residue was washed...

Embodiment 2

[0053] Weigh 250 g of cartilage and 750 g of trachea, and wash them twice with drinking water. Put it into a cooking pot, add distilled water to immerse, heat up to 100°C, and cook for 2 hours. After cooling down to 50°C, a small amount of sodium hydroxide was added to adjust the pH of the feed solution to 9.00.

[0054] 30 g of porcine pancreas and 10 g of lipase were added to the cooking liquid, supplemented by low-speed stirring with a stirring paddle, and the temperature was kept at 50°C for 2.0 h of reaction.

[0055] In the above feed solution, a mixed enzyme containing collagenase and flavor protease was added according to the proportion of 0.40% of the raw material mass (the mass ratio of the two in the mixed enzyme was 5:3), and the temperature was maintained at 50°C for 2.0 h. (The pH is stable after the primary enzymatic hydrolysis, which is suitable for the secondary enzymatic hydrolysis reaction, and there is no need to add additional acid and alkali to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com