Photoinduced carbon quantum dot and preparation method thereof

A carbon quantum dot, photoinduced technology, which is applied in the field of photosynthesis of carbon quantum dots and its preparation, can solve the problems of large differences in properties between carbon quantum dots and precursors, the inability to retain the excellent properties of the precursors, and the cumbersome preparation process, and achieve obvious excitation. Dependency, broadening design ideas, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (synthesis of carbon quantum dot precursor)

[0033] (1) The synthesis of compound 2, the specific steps are as follows:

[0034] Sodium hydride (0.24 g, 10 mmol) and phenothiazine (1.99 g, 10 mmol) were added to a solution in dry DMF (20 mL); after stirring the solution at room temperature for 30 min, 4-fluorophenylsulfone (2.54 g , 10 mmol), then the mixture was stirred at 130 °C for 2 hours under a nitrogen atmosphere; after sufficient reaction, the mixture was poured into ice water (300 mL) to precipitate, and the precipitate was collected by filtration, and the precipitate was passed through column chromatography (DCM:PE = 3 : 1, v / v) was further purified to obtain a pale yellow solid (60% yield), which was designated as compound 2;

[0035] (2) The synthesis of compound 3, the specific steps are as follows:

[0036] Add 5-nitroindole (0.81 g, 5 mmol), potassium carbonate (7.90 g, 50 mmol) and compound 2 (2.17 g, 5 mmol) into a round bottom flask and...

Embodiment 2

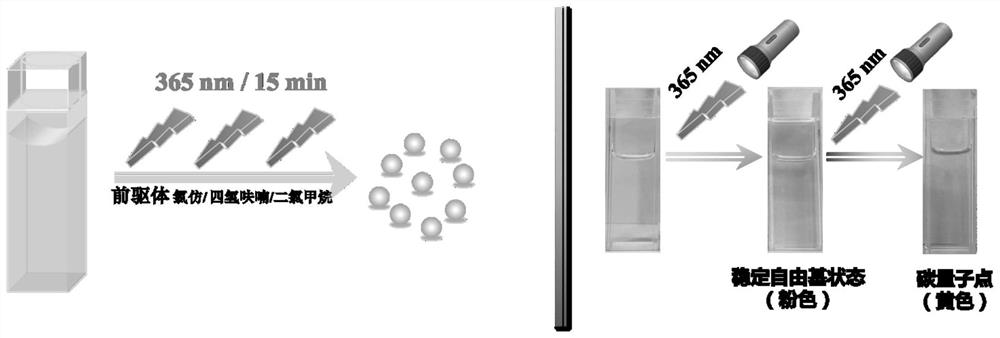

[0037] Embodiment 2 (synthesis of carbon quantum dots)

[0038] Step (1) Dissolve 10 mg of compound 3 in chloroform solvent to prepare 2*10 -4 mol / L chloroform dilute solution.

[0039] Step (2) Place the beaker containing the solution under a 5W or higher ultraviolet light source, and the beaker is 10cm away from the ultraviolet light source.

[0040] Continue to light for 15 minutes at room temperature.

[0041] Step (3) The solution in the beaker was spin-dried, the spin-dried powder was washed and suction-filtered with petroleum ether, and the powder after the suction-filtration of the upper layer was dried in a vacuum oven for 24 hours to obtain carbon quantum dots.

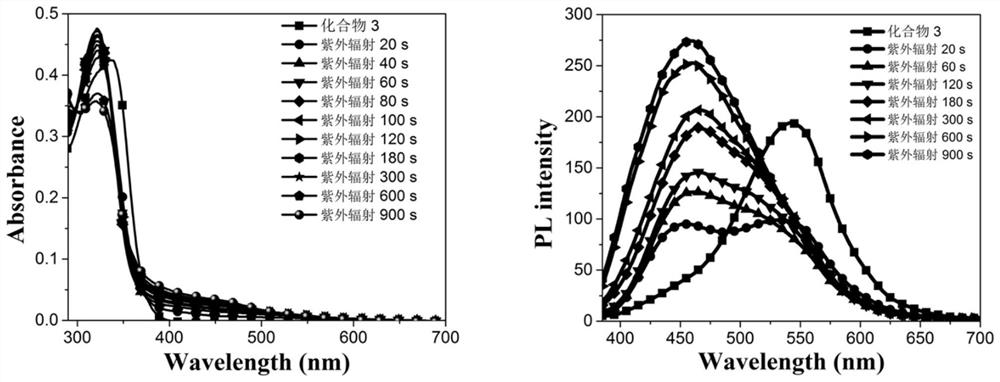

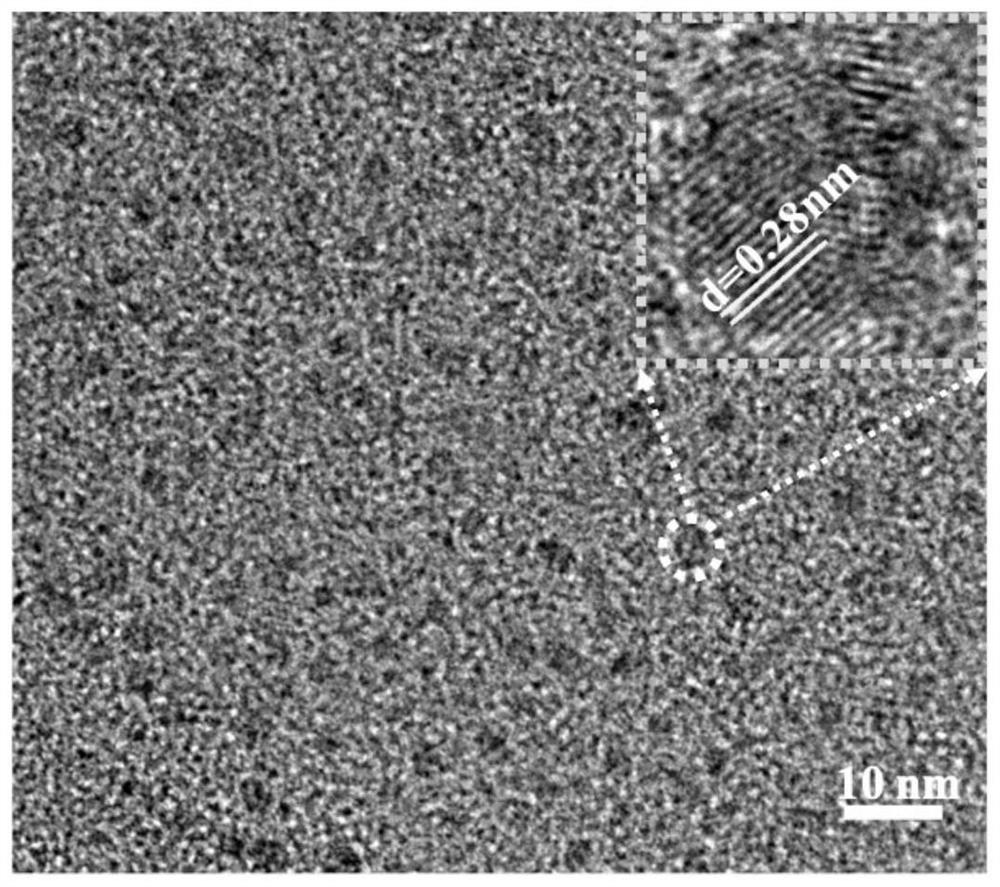

[0042] In step (2), the change of the solution under ultraviolet light for 15 minutes is as follows: figure 1 Shown; at the same time, take the solutions in different time periods during the illumination process and put them into 3 mL cuvettes, and measure the changes of their absorption and emission spec...

Embodiment 3

[0046] A preparation method of photoinduced carbon quantum dots, the specific steps are the same as in Example 2, only the solution chloroform in step (1) is replaced by dichloromethane. The quantum dot particles thus obtained are uniformly dispersed, but the width of the ultraviolet absorption spectrum is relatively narrow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com