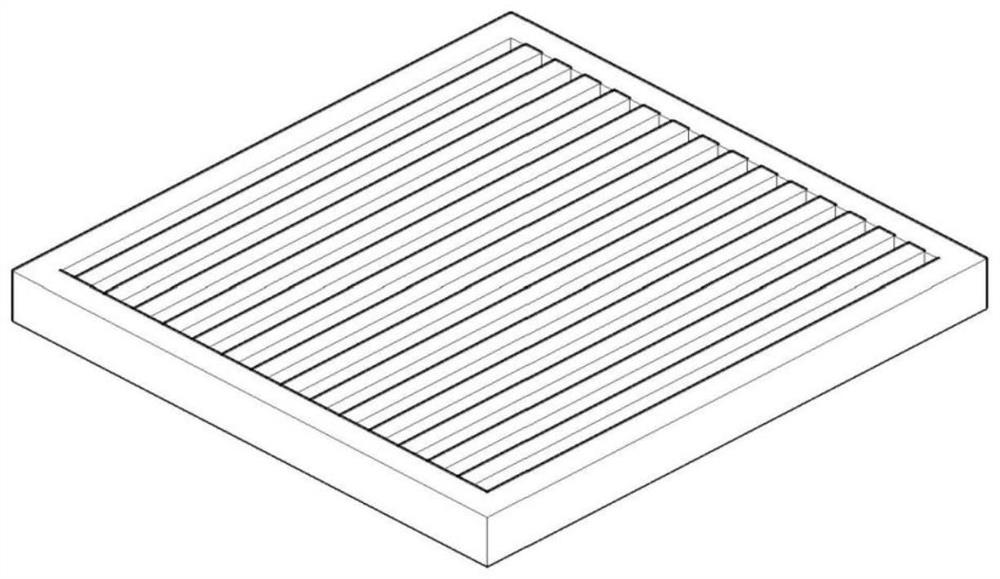

Preparation method of manifold type all-diamond micro-channel radiator

A diamond and microchannel technology, applied in heat exchange equipment, lighting and heating equipment, etc., can solve the problems of thermal management system design requirements that cannot effectively cope with ultra-high heat flux devices, small microchannel size, and increased packaging difficulty. Achieving the effect of good shape, strong heat exchange capacity and high encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Use a DC plasma jet chemical vapor deposition device to grow a diamond thick film on a molybdenum substrate with a diameter of 100mm and a thickness of 50mm plated with a composite transition layer of Ti, Mo, Si, and W. Grind the substrate with diamond abrasive paste with a particle size of 0.5 μm for 5 min, and rinse with acetone twice. Put it into the chamber, set the deposition temperature range to 850-950°C, Ar flow rate to 4slm, H 2 The flow is 7.8slm, CH 4 The flow rate is 100sccm, every growth 100h, the CH 4 The flow rate was increased to 130sccm, nucleation was performed for 15 minutes, and then CH was closed 4 , keep H 2 / Ar plasma treatment for 10 min. Then set the CH 4 Flow to 120sccm and continue to grow for 100h. Until the deposition time is 350h, at the same time, the deposition table is continuously reduced at a rate of 15μm / h during the diamond film deposition stage, and the distance between the deposition surface and the anode is always kept at...

Embodiment 2

[0043] 1. Select a direct current plasma jet chemical vapor deposition device to prepare a diamond thick film on a graphite substrate with a diameter of 100 mm, use a diamond abrasive paste with a particle size of 0.5 μm to grind the substrate for 5 minutes, wash it with acetone twice, and then dry it and put it into chemical vapor deposition In the system; a diamond thick film is prepared on the surface of the above-mentioned substrate by using direct-flow jet CVD technology. The deposition process is set to: CH 4 The flow rate is 120sccm, H 2 The flow rate is 7.5slm, the Ar flow rate is 3.7, the power is about 22kW, and the substrate temperature is about 900°C. Every 120h of growth, the CH 4 Increase the flow rate by 50 sccm, nucleate for 10 minutes, and then close CH 4 , keep H 2 / Ar plasma treatment for 20min, and then CH 4 Flow was reduced by 30 sccm to continue growth. At the same time, during the diamond film deposition stage, the deposition table is reduced at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com