A kind of composite carrier material for biological fluidized bed and preparation method thereof

A biological fluidized bed and composite carrier technology, which is applied in the field of composite carrier materials for biological fluidized beds and its preparation, can solve the problems of weak binding strength, low adsorption performance, and poor pertinence of a single carrier, and is conducive to the growth of film growth , short film-hanging time and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

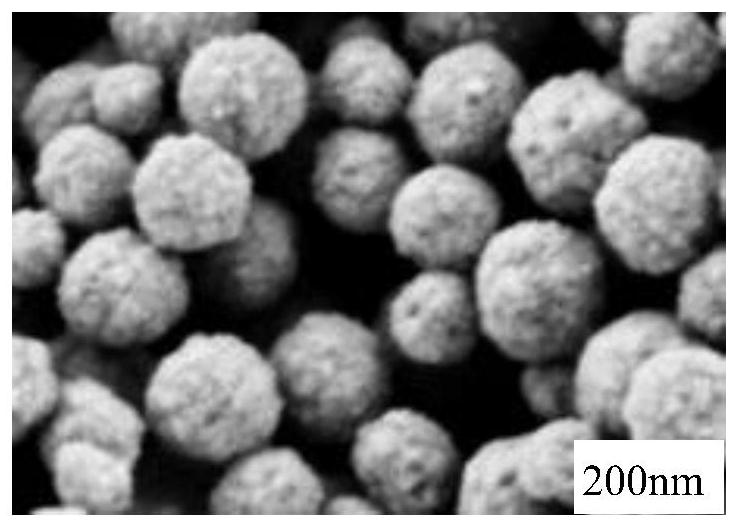

Image

Examples

preparation example Construction

[0026] A preparation method for a composite carrier material for a biological fluidized bed, comprising the steps of:

[0027] 1) Weigh diatomaceous earth, put it in 1mol / L sodium hydroxide solution, soak it at 40°C for 1h, take it out, wash it with water until the surface is neutral, and then calcinate it at 450°C for 2h; after cooling to room temperature Add it into 1mol / L hydrochloric acid solution, soak it at 40°C for 1h, take it out, wash it with water until the surface becomes neutral, calcinate it at 450°C for 1h, wash it with water and dry it to obtain purified diatomite;

[0028] 2) Take purified diatomite and KH570 and add them to anhydrous toluene at a mass ratio of 1:2, ultrasonically disperse them evenly, heat and reflux for 4-5 hours, and centrifuge after natural cooling, collect the solids, wash with ethanol, dry, and grind , to obtain modified diatomite powder;

[0029] 3) Add equal volumes of ethanol and water into the reaction flask respectively, under the p...

Embodiment 2

[0033] 1) Weigh diatomaceous earth, put it in 1mol / L sodium hydroxide solution, soak it at 40°C for 1h, take it out, wash it with water until the surface is neutral, and then calcinate it at 450°C for 2h; after cooling to room temperature Add it into 1mol / L hydrochloric acid solution, soak it at 40°C for 1h, take it out, wash it with water until the surface becomes neutral, calcinate it at 450°C for 1h, wash it with water and dry it to obtain purified diatomite;

[0034] 2) Add purified diatomite and KH570 into 50ml of anhydrous toluene at a mass ratio of 1:2, disperse evenly with ultrasound, heat and reflux for 4-5h, and centrifuge after natural cooling, collect the solids, wash with ethanol, and dry. Grinding to obtain modified diatomite powder;

[0035]3) Add equal volumes of ethanol and water into the reaction flask respectively, under the protection of nitrogen, add the modified diatomite powder into the reaction flask, stir to make it evenly dispersed, and then continue ...

Embodiment 3

[0038] Same as Example 2, the difference is that KH570 is replaced by KH560.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com