Preparation method of spherical silica powder

A technology of spherical silicon micropowder and silicon source, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of wide particle size distribution, high equipment requirements, low spherical rate, etc., and achieve uniform particle size distribution, dense and smooth surface of the sphere, and flow good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of spherical micro-silicon powder, which comprises the following steps:

[0032] (1) Add 20 g of sodium silicate into a membrane emulsification device with a membrane aperture of 10 μm to form a dispersed phase silicon source;

[0033] (2) Add 0.5 g of Tween-60 into 50 ml of deionized water and mix evenly to form a mixed solution;

[0034] (3) adding the dispersed-phase silicon source in step (1) to the mixed solution in step (2) under a pressure of 0.1 MPa to form a stable emulsion;

[0035] (4) Add 1g of ammonia water to the stable emulsion in step (3), stir for 45 minutes to obtain particle slurry;

[0036] (5) centrifuging the granular slurry obtained in step (4), and drying the obtained powder at 80° C. for 5 hours to obtain a dry powder;

[0037] (6) Calcining the dry powder obtained in step (5), the heating rate is 3 hours to 600° C., and the holding time is 8 hours to obtain spherical silicon oxide micropowder.

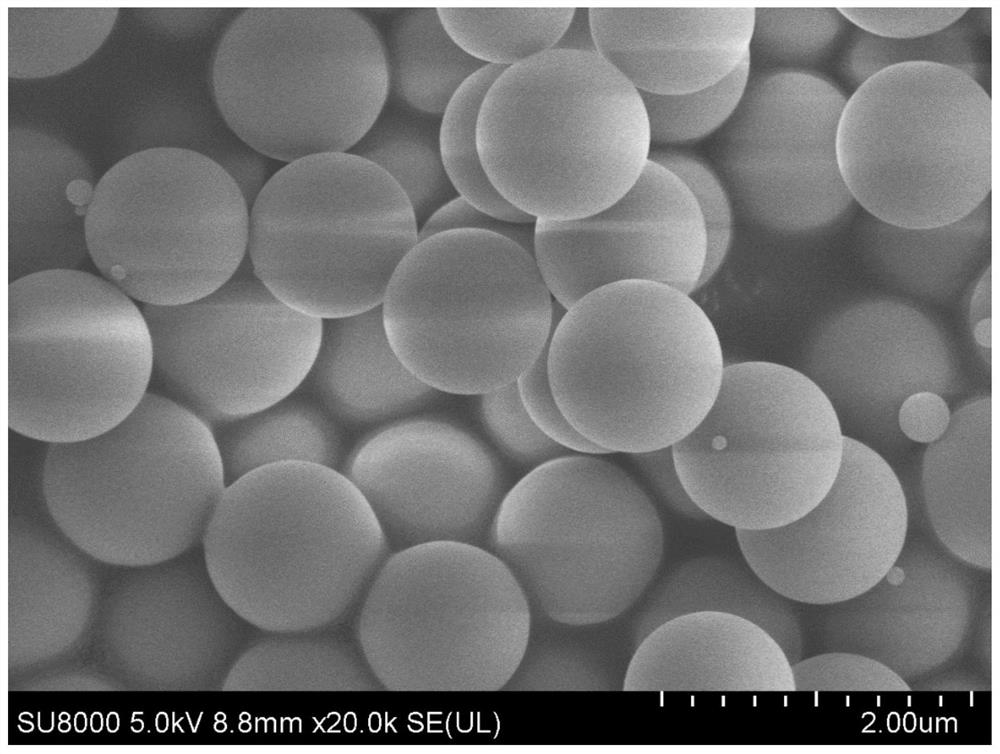

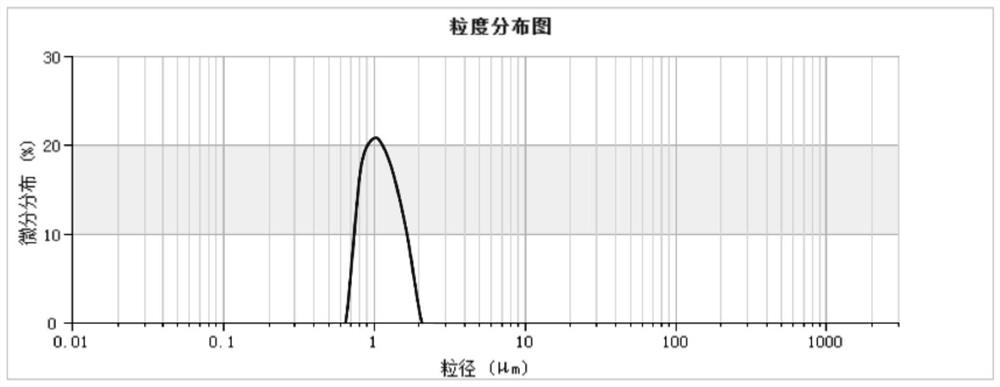

[0038] From figure 1 It ...

Embodiment 2

[0040] A preparation method of spherical micro-silicon powder, which comprises the following steps:

[0041] (1) Add 30 g of sodium silicate into a membrane emulsification device with a membrane aperture of 20 μm to form a dispersed phase silicon source;

[0042] (2) Add 0.5 g of Tween-60 into 50 parts of deionized water and mix evenly to form a mixed solution;

[0043] (3) adding the dispersed-phase silicon source in step (1) to the mixed solution in step (2) under a pressure of 0.1 MPa to form a stable emulsion;

[0044] (4) 1g of formic acid is added in the stable emulsion in step (3), stirred for 30 minutes to obtain particle slurry;

[0045] (5) centrifuging the granular slurry obtained in step (4), and drying the obtained powder at 80° C. for 5 hours to obtain a dry powder;

[0046] (6) Calcining the dry powder obtained in step (5), the heating rate is 3 hours to 600° C., and the holding time is 8 hours to obtain spherical silicon oxide micropowder.

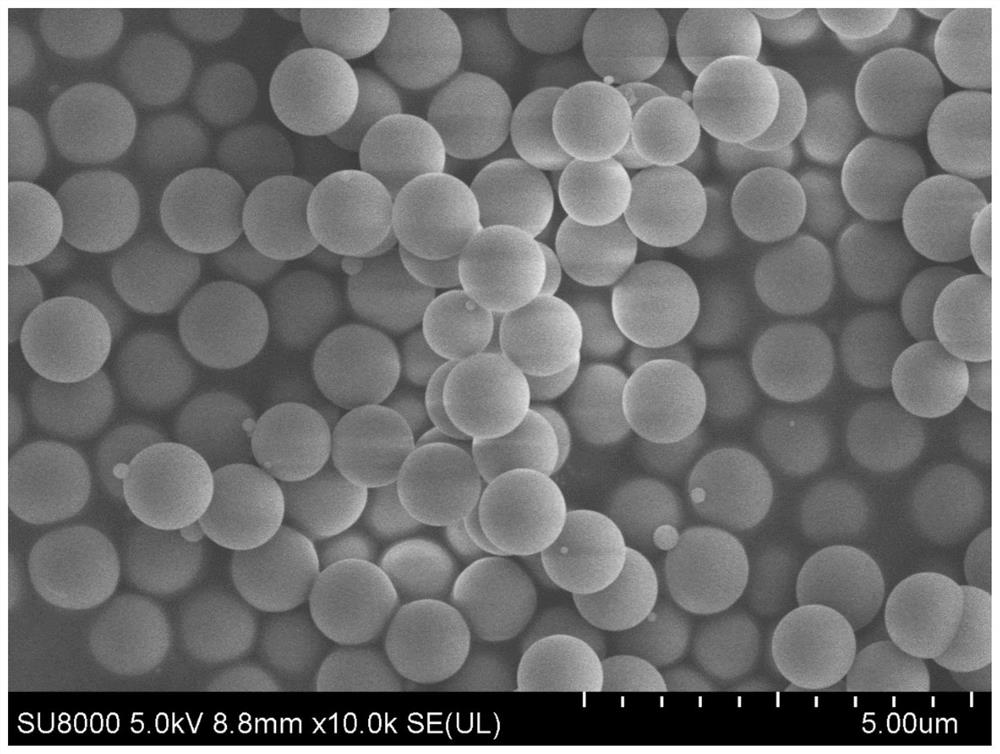

[0047] The parti...

Embodiment 3

[0049] A preparation method of spherical micro-silicon powder, which comprises the following steps:

[0050] (1) Add 30 g of methyltrimethoxysilane into a membrane emulsification device with a membrane aperture of 30 μm to form a dispersed phase silicon source;

[0051] (2) Add 0.3 parts of Span-80 into 80 parts of deionized water and mix evenly to form a mixed solution;

[0052](3) adding the dispersed-phase silicon source in step (1) to the mixed solution in step (2) under a pressure of 0.05 MPa to form a stable emulsion;

[0053] (4) Add 1g of ammonia water to the stable emulsion in step (3), stir for 30 minutes to obtain particle slurry;

[0054] (5) centrifuging the particle slurry obtained in step (4), and drying the obtained powder at 100° C. for +6 hours to obtain a dry powder;

[0055] (6) Calcining the dry powder obtained in step (5), the heating rate is 4 hours to 500° C., and the holding time is 5 hours to obtain spherical silicon oxide micropowder.

[0056] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com