High-adsorption bismuth oxyiodide visible-light-driven photocatalyst and application thereof

A technology of bismuth oxyiodide and visible light, applied in the field of new materials, can solve the problems of limiting bismuth oxyhalide, high recombination rate of photogenerated holes and photogenerated electrons, low light absorption efficiency of pure-phase bismuth oxyhalide, etc., so as to reduce production costs. , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

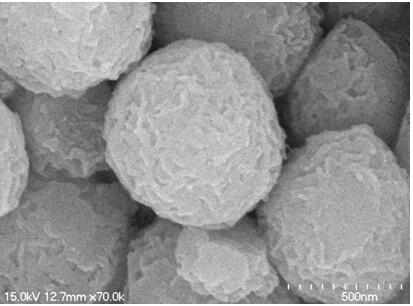

[0042] A solution is composed of bismuth nitrate pentahydrate, glacial acetic acid and ethanol, the ratio of which is 1:1.2:2.4 (molar mass: volume: volume); A solution is obtained after uniform dissolution; 0.04M povidone-iodine aqueous solution is configured, namely B solution .

[0043]Add solution A to solution B dropwise, control the molar ratio of bismuth and iodine to be 1:3, and obtain a uniform mixed solution through continuous stirring overnight at room temperature; transfer the mixed solution to a three-necked flask, install the condensing reflux device and Stirring device, placed in a constant temperature oil bath, control the reaction temperature at 60°C, the reaction time is 6h, after cooling, centrifuge, wash with deionized water and absolute ethanol respectively, and dry the reaction product in an oven at 80°C 8h. The photocatalyst of bismuth oxyiodide with high adsorption was obtained by careful grinding with a mortar.

[0044] The high-adsorption ultrafine ...

Embodiment example 2

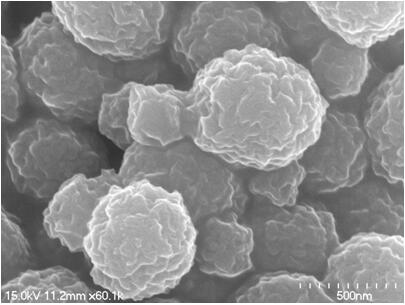

[0046] A solution is composed of anhydrous bismuth chloride, 1mol / L dilute hydrochloric acid and isopropanol, the ratio is 1:2:6 (molar mass: volume: volume); A solution is obtained after uniform dissolution; configure 0.1M polydimensional Ketone-iodine aqueous solution, that is, B solution.

[0047] Add solution A to solution B dropwise, control the molar ratio of bismuth and iodine to be 1:1, and keep stirring overnight at room temperature to obtain a uniform mixed solution; transfer the mixed solution to a three-necked flask, install the condensing reflux device and Stirring device, placed in a constant temperature oil bath, control the reaction temperature at 80°C, the reaction time is 6h, after cooling, centrifuge, wash with deionized water and absolute ethanol respectively, and dry the reaction product in an oven at 90°C 6h. The photocatalyst of bismuth oxyiodide with high adsorption was obtained by careful grinding with a mortar.

[0048] The high-adsorption ultrafine...

Embodiment example 3

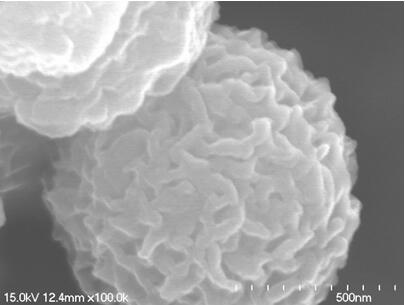

[0050] A solution is composed of bismuth acetate, glacial acetic acid and ethylene glycol, and its ratio is 1:3:8 (molar mass: volume: volume); A solution is obtained after uniform dissolution; 0.2M povidone-iodine aqueous solution is prepared, that is, B solution .

[0051] Add solution A dropwise to solution B, control the molar ratio of bismuth and iodine to 1:4, and keep stirring overnight at room temperature to obtain a uniform mixed solution; transfer the mixed solution to a three-necked flask, and install the condensing reflux device and a stirring device, placed in a constant temperature oil bath, control the reaction temperature at 90°C, and the reaction time is 6h. After cooling, centrifuge and separate, wash with deionized water and absolute ethanol respectively, and put the reaction product in an oven at 90°C Dry for 6h. The photocatalyst of bismuth oxyiodide with high adsorption was obtained by careful grinding with a mortar.

[0052] The high-adsorption ultrafi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com