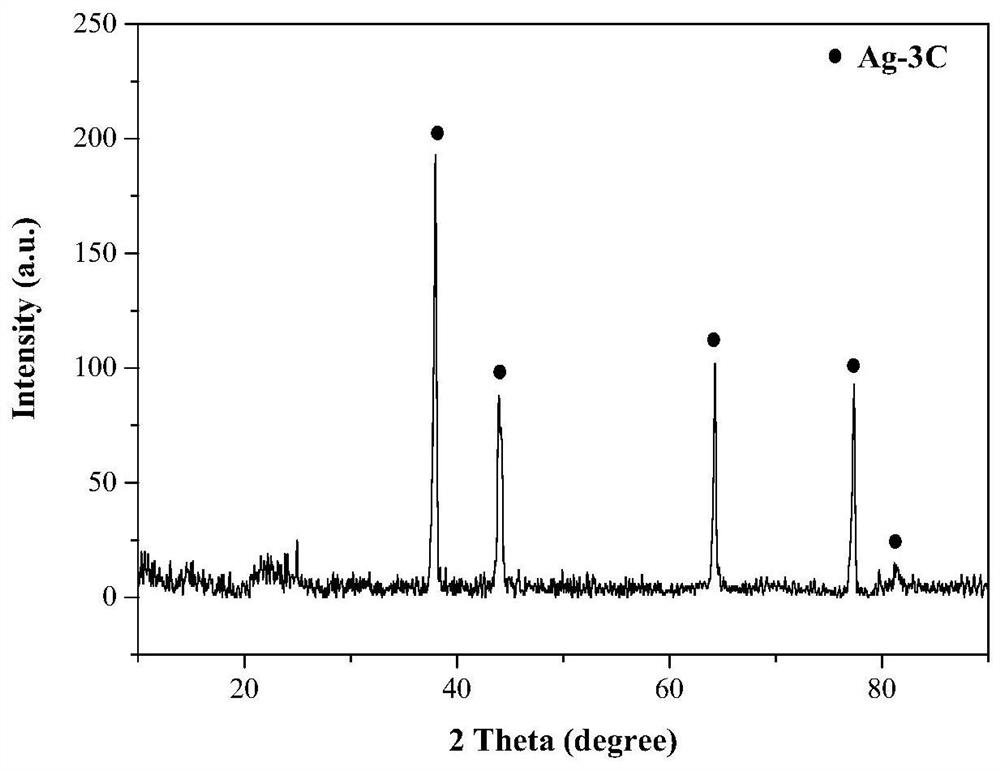

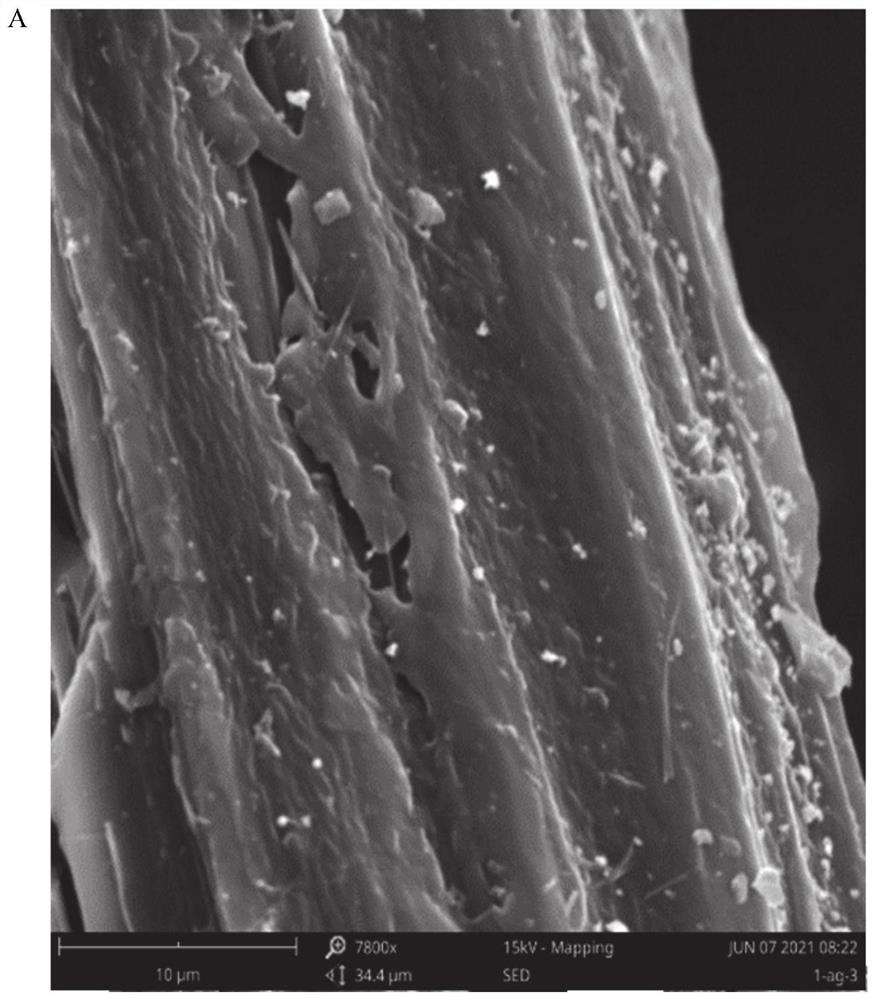

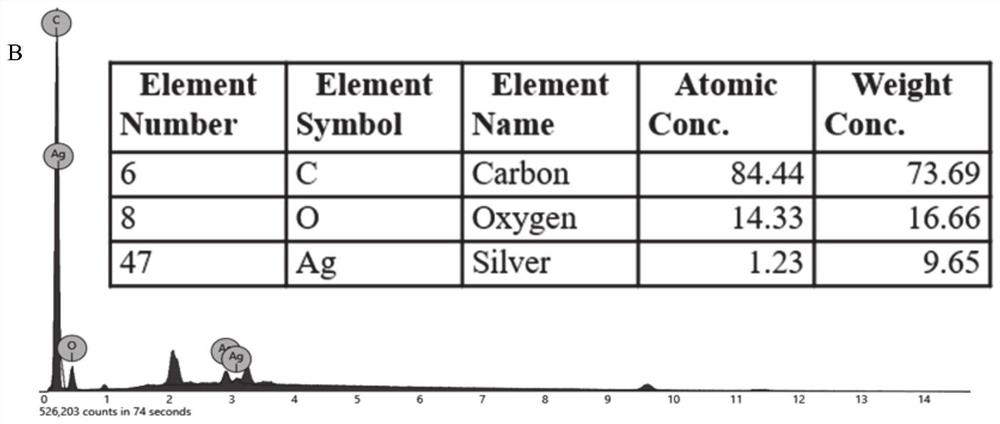

Preparation method and application of straw-based antibacterial activated carbon

A technology of activated carbon and straw, applied in the field of activated carbon, can solve the problems of high cost of antibacterial carrier, complex preparation process, poor adsorption, etc., and achieve the effects of abundant micropores, strong antibacterial broad-spectrum and strong adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of preparation method of straw-based antibacterial activated carbon is as follows:

[0036] (1) Pretreatment of rice straw to obtain straw powder: picking, drying, grinding and sieving the waste straw to obtain a powder with a particle size of 80 mesh;

[0037] (2) Pretreating the straw powder by microwave method to obtain a derived carbonaceous mesophase: sending the straw powder dried in step (1) into a microwave reactor, and heat-treating at 90° C. for 5 minutes;

[0038] (3) Carbonize the carbonaceous mesophase to obtain pyrolytic carbon: place the carbonaceous mesophase derived in step (2) in a tube furnace, purging with nitrogen, set the pyrolysis temperature to 550°C, and the pyrolysis time to 60 minutes, the heating rate is 10°C / min;

[0039] (4) Make silver nitrate antibacterial agent and potassium hydroxide activator into a solution, then impregnate pyrolytic carbon in 150mL solution containing silver nitrate and potassium hydroxide, wher...

Embodiment 2

[0043] Embodiment 2: a kind of preparation method of straw-based antibacterial activated carbon is as follows:

[0044](1) Cotton stalks are pretreated to obtain straw powder: the waste straws are selected, dried, ground, and sieved to obtain a powder with a particle size of 100 mesh;

[0045] (2) Pretreating the straw powder by microwave method to obtain a derived carbonaceous mesophase: sending the straw powder dried in step (1) into a microwave reactor, and heating at 60° C. for 8 minutes;

[0046] (3) Carbonize the carbonaceous mesophase to obtain pyrolytic carbon: place the carbonaceous mesophase derived in step (2) in a tube furnace, purging with nitrogen, set the pyrolysis temperature to 650°C, and the pyrolysis time to 45 minutes, the heating rate is 5°C / min;

[0047] (4) Make a solution of zinc sulfate antibacterial agent and potassium hydroxide activator, then impregnate pyrolytic carbon in 150mL solution containing zinc sulfate and potassium hydroxide, wherein the ...

Embodiment 3

[0079] Antibacterial detection: Escherichia coli and Staphylococcus aureus are used as the strains, and the sterilization rate is detected and calculated using the scheme in GB21551.2-2010.

[0080] The antibacterial experiment process is as follows: boil solid medium (10g of peptone, 5g of beef extract, 5g of sodium chloride, 17.5g of agar, 1000ml of distilled water), pour it into an Erlenmeyer flask, and pass through a pressure steam sterilizer under high pressure (120°C, 1.5 MPa) after being sterilized for 20 minutes, it was dispensed into petri dishes while it was hot, and cooled under aseptic conditions to obtain a solid medium. The cultured Escherichia coli liquid was made into a concentration of 5.0×10 5 -10×10 5 For cfu / ml bacterial suspension, take a round sample with a diameter of 50mm, draw 1.0±0.1ml of bacterial solution and inoculate it on the sample to ensure that the bacterial solution is evenly distributed and does not touch the wall. Tighten the cover to prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com