A kind of iron trench castable combined with ammonium ion stabilized silica sol

A technology of iron ditch castables and ammonium ions, which is applied in the field of refractory materials, can solve the problems of slag-iron scour resistance and erosion resistance deterioration, lower corrosion resistance of castables, and narrow dehydration temperature range, so as to reduce material costs and simplify Product formula, good effect of anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

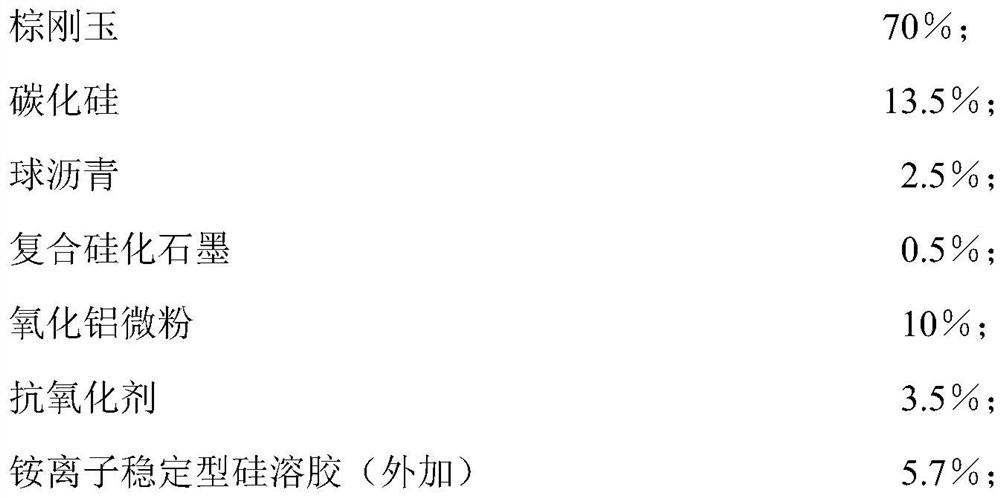

[0038] Provided is a sol-bonded castable for iron ditch which is composed of the following components and percentages by weight:

[0039]

Embodiment 2

[0041] Provided is a sol-bonded castable for iron ditch, which is composed of the following components and percentages by weight:

[0042]

Embodiment 3

[0044] Provided is a sol-bonded castable for iron ditch, which is composed of the following components and percentages by weight:

[0045]

[0046]

[0047] Using sodium hydroxide stabilized silica sol (silicon dioxide content of 30%) to prepare iron trench castables, it is composed of the following components and weight percentages:

[0048]

[0049] The physical and chemical parameters of the iron trench casting obtained in Examples 1, 2, and 3 are shown in Table 1.

[0050] Table 1

[0051]

[0052]

[0053]The pH value of conventional sodium hydroxide-stabilized silica sol is between 8-10, and the sodium ion content is about 0.3%, resulting in low thermal flexural strength, because the sodium hydroxide-stabilized silica sol promotes metal aluminum and metal silicon. reaction. The invention adopts ammonium ion-stabilized silica sol as the binding agent of the castable for iron ditch, strictly controls the quality of raw materials, and focuses on improving t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com