Preparation method of biological membrane as well as product and application of biological membrane

A biofilm and animal technology, which is applied in tissue regeneration, medical science, surgery, etc., can solve the problems of large dosage of drugs, large residues, and incomplete decellularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

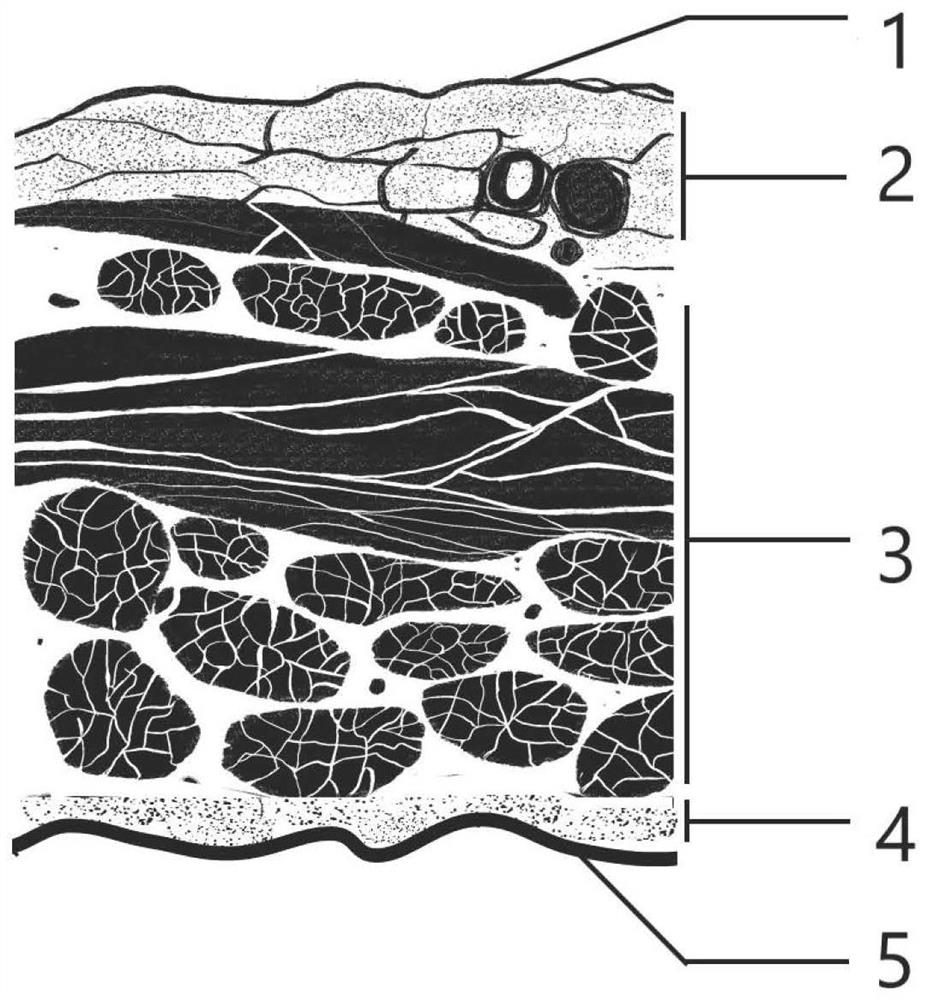

[0100] The present embodiment provides a kind of biofilm, and the preparation method of described biofilm comprises the following steps:

[0101] (1) Soak 100g of fresh porcine bladder tissue material in 1L of 10wt% acetylcysteine solution for 2h;

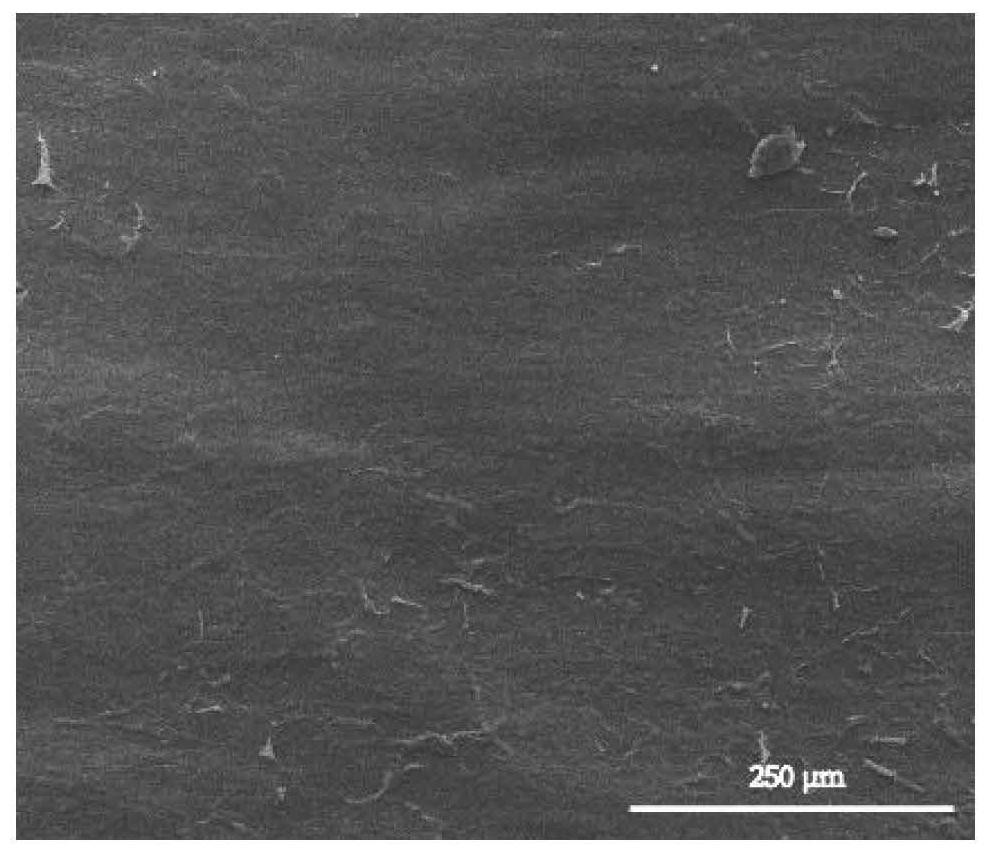

[0102] (2) Cut the product obtained in step (1) at 25°C with a slicing device to remove a film layer with a thickness of 1mm from the bladder material serosa layer, wherein the specific process parameters for mechanical cutting device removal are: voltage 220V, power 3600W, The cutting speed is 15mm / s, and the surface roughness of the material after cutting is less than 100μm;

[0103] (3) Soak 100 g of the product obtained in step (2) in 1 L of 2 wt % trypsin solution at 25° C. for 4 h;

[0104] (4) Soak the product obtained in step (3) at 5° C. for 2 hours in 1 L of a mixed aqueous solution containing 1 mol / L sodium hydroxide and 3% acetylcysteine;

[0105] (5) Soak the product obtained in step (4) at 25°C for 16 hours in 1L ...

Embodiment 2

[0112] This embodiment provides a biofilm, and the preparation method of the biofilm specifically includes the following steps:

[0113] (1) Soak 100g of fresh pig stomach tissue material in 1L of 5wt% sodium citrate solution for 4h;

[0114] (2) The product obtained in step (1) is used at normal temperature to remove a membrane layer with a thickness of 1 mm from the gastric serosa layer using a slicing device, wherein the specific process parameters of mechanical cutting device removal are: voltage 220V, power 3600W, cutting rate 15mm / s, the surface roughness of the material after cutting is <100μm;

[0115] (3) Soak 100 g of the product obtained in step (2) in 1 L of 1 wt% 1398 protease solution at 25° C. for 5 h;

[0116] (4) Soak the product obtained in step (3) at 10° C. in 1 L of 2 mol / L sodium carbonate and 2% sodium citrate mixed aqueous solution for 4 h;

[0117] (5) Soak the product obtained in step (4) at 25°C for 15 hours in 1L of decellularized solution, which ...

Embodiment 3

[0124] This embodiment provides a biofilm, and the preparation method of the biofilm specifically includes the following steps:

[0125] (1) Soak 100 g of fresh bovine large intestine tissue material in 1 L of 15% edetate disodium solution for 2 hours;

[0126] (2) The product obtained in step (1) is used at normal temperature to remove a film layer with a thickness of 3 mm from the serosa layer of the large intestine tissue using a slicing device. The specific process parameters for mechanical cutting device removal are: voltage 220V, power 3600W, cutting The speed is 15mm / s, and the surface roughness of the material after cutting is <100μm;

[0127] (3) Soak 100 g of the product obtained in step (2) in 1 L of 3 wt% trypsin solution at 25° C. for 3 h;

[0128] (4) Soak the product obtained in step (3) in 1 L of 3 mol / L calcium hydroxide and 2% edetate disodium mixed aqueous solution at 15° C. for 1 h;

[0129] (5) Soak the product obtained in step (4) at 15°C for 22 hours i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com