Method and device for continuously producing ellagic acid

A technology of ellagic acid and dopamine, applied in the field of tannin degradation, can solve the problems of strict requirements for enzymatic conversion conditions, cumbersome process, difficult sewage treatment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

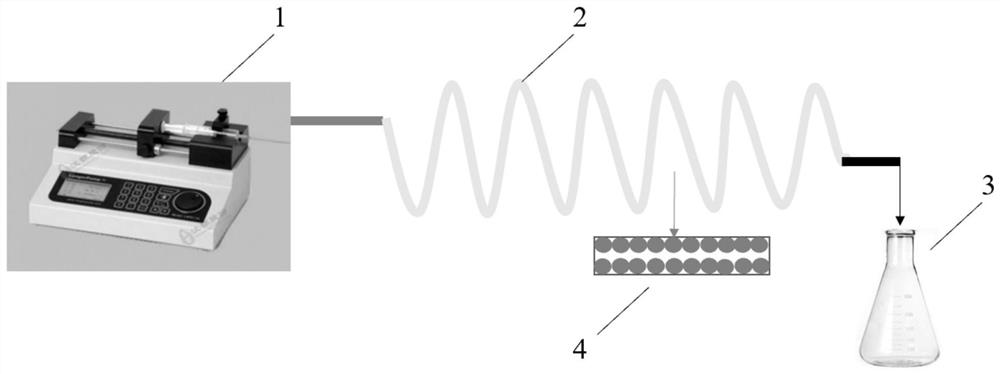

Method used

Image

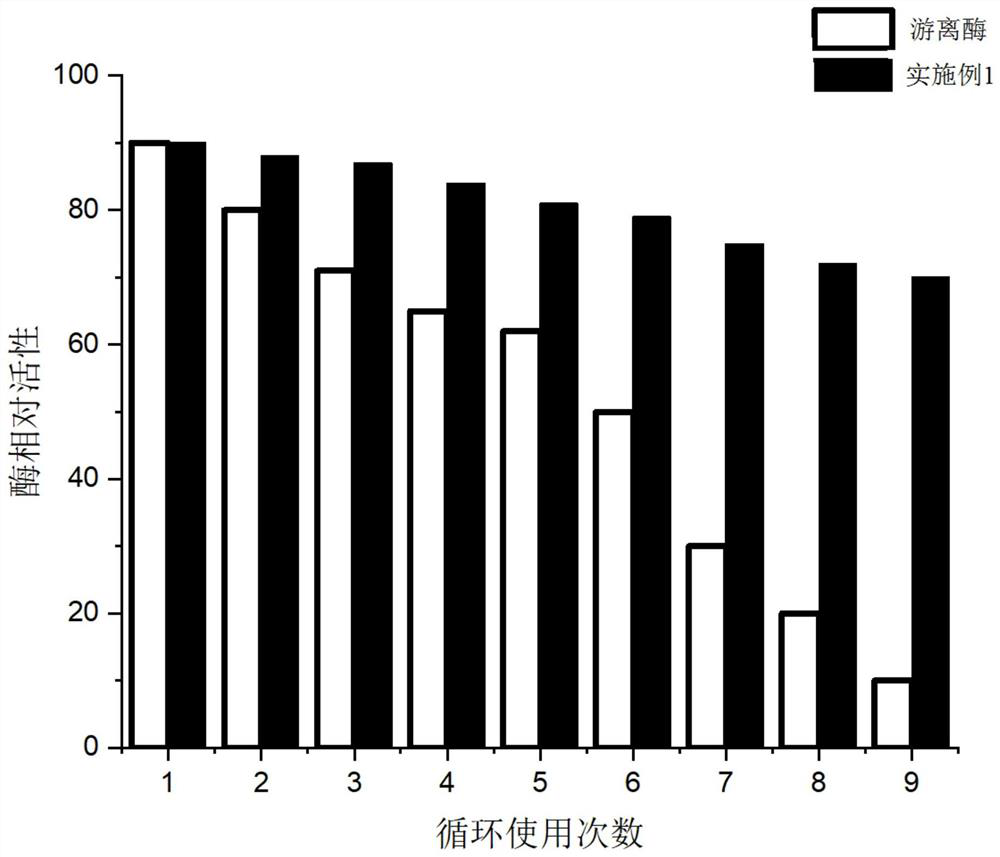

Examples

preparation example Construction

[0027] According to the present invention, the preparation method of the dopamine coating comprises: aminating the surface of the silica gel to obtain an aminated silica gel, and modifying the aminated silica gel with a fixative solution containing dopamine. The inventors found that in this preferred embodiment, it is beneficial to improve the immobilization efficiency and stability of the dopamine coating on tannase.

[0028] According to the present invention, the temperature for modifying the aminated silica gel with a fixative solution containing dopamine is 40-60°C, specifically 40°C, 45°C, 50°C, 55°C, 60°C, or between the above two values any value in between. After the modification, the modified silica gel can be washed, for example, Tris-HCl buffer solution at a flow rate of 50-150 μL / m can be used for washing.

[0029] According to the present invention, the process of the amination treatment includes: contacting the surface of the silica gel with an amination soluti...

Embodiment 1

[0046] S1. Choose a silicone tube with a length of 0.5m and an inner diameter of 0.03cm. First, use a syringe to inject 1M sodium hydroxide solution into the silicone tube for cleaning (flow rate is 100μL / min, flow rate is 1mL), and then use a syringe to make the volume fraction 10%. 3-Aminopropyltrimethoxysilane (APTES)-ethanol solution (flow rate: 100 μL / min, flow rate: 1 mL) was injected into the silica gel tube, the temperature of the incubator was adjusted to 60 ° C, and the silica gel tube was incubated at 60 ° C for 3 h to The surface of the inner cavity of the silicone tube is aminated, and the silicone tube treated with APTES is rinsed with ethanol injected from a syringe, and then baked in a thermostat at 125°C for 1 hour to dry to obtain aminated silica gel;

[0047] S2. Adjust the temperature of the incubator to 50°C, inject 1.5mL of fixative solution (with a dopamine concentration of 1mg / ml) into the silicone tube at a flow rate of 1 μL / min at 50°C with a syringe, ...

Embodiment 2

[0051] S1. Choose a silicone tube with a length of 0.4m and an inner diameter of 0.05cm. First, use a syringe to inject 1M sodium hydroxide solution into the silicone tube for cleaning (flow rate is 100μL / min, flow rate is 1mL), and then use a syringe to inject a volume fraction of 5%. 3-aminopropyltrimethoxysilane (APTES)-ethanol solution (flow rate: 50 μL / min, flow rate: 2.6 mL) was injected into the silica gel tube, the temperature of the incubator was adjusted to 50 °C, and the silica gel tube was incubated at 50 °C for 4 h The surface of the inner cavity of the silicone tube is aminated, and the silicone tube treated with APTES is rinsed with ethanol injected into a syringe, and then dried in a thermostat at 110°C for 1.5 hours to obtain aminated silica gel;

[0052] S2. Adjust the temperature of the incubator to 40°C, inject 3.8mL of fixative solution (with a dopamine concentration of 0.5mg / mL) into the silicone tube at a flow rate of 1.5μL / min at 40°C with a syringe, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com