A method for reducing loss of raw liquid sulfonated carbon disulfide

A technology for liquid sulfonation of carbon disulfide and carbon disulfide, applied in chemical instruments and methods, separation methods, fiber chemical characteristics, etc., can solve the problems of inability to reduce the consumption of raw liquid sulfonation CS2, inability to improve the utilization rate of CS2, and high equipment investment, and achieve reduction Effects of CS2 Escape, Reducing CS2 Loss, and Improving Utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

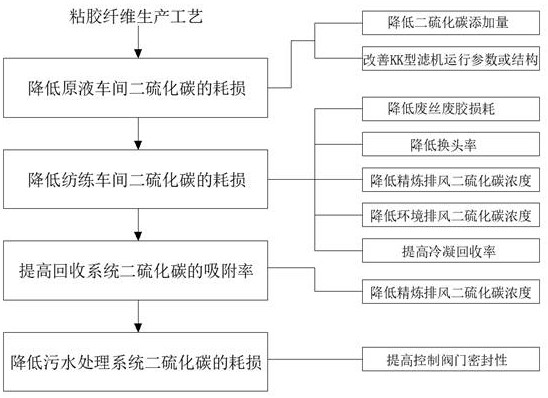

Image

Examples

Embodiment 1

[0033] A method for reducing the loss of stoste sulfonated carbon disulfide, comprising the following steps:

[0034] Stock solution workshop: by reducing the CS in the stock solution workshop 2 and improve the operating parameters of the KK-type filter in the raw liquid workshop. Adjust the air pressure control system and improve the structure of the KK-type filter. The air tightness of the machine, in which: the filter with good corrosion resistance is set as one of the metal rubber filter, nylon filter or metal filter, so as to improve the sulfonated CS 2 The utilization rate of the product can be reduced, the maturity of the product can be slowed down, the quality fluctuation of the finished product can be reduced, and the CS of the dope workshop can be reduced 2 loss. When the stock solution sulfonated CS 2 The addition rate decreased from 290kg / T to 278kg / T wire, and the ton wire decreased by 2.4kg / T wire. When the stock solution sulfonated CS 2 When the addition rat...

Embodiment 2

[0043] The procedure of this embodiment is the same as that of Example 1, the difference is that: the high-concentration carbon disulfide gas produced by the stock solution workshop, the spinning workshop and the acid station is connected to the condensation recovery system, and the stock solution workshop, the spinning workshop and the The direct discharge valve of the internal leakage of the acid station is used to reduce the concentration of the ambient exhaust air, thereby reducing the loss of carbon disulfide. The combined seal used is made of 316L stainless steel and graphite with strong corrosion resistance, so that the 2 Loss has dropped 0.31kg / T wire, all the other are identical with embodiment 1.

Embodiment 3

[0045] The steps of this embodiment are the same as those of Embodiment 2, except that the condensation recovery system includes a pretreatment device, a condensation treatment device and a secondary condensation treatment device, the pretreatment device is set as a long conduit for improving heat exchange efficiency, and the condensation The condenser tubes in the treatment device and the secondary condensation treatment device are made of glass fiber reinforced plastics to avoid fouling, and the cooling water outlets in the condensation recovery system are equipped with temperature sensors and pressure sensors. Steam pressure, increase the contact area between steam and fiber, increase cooling water and CS 2 The way of steam contact area improves condensation effect and reduces CS 2 Consume 0.42kg / T silk, all the other are identical with embodiment 2.

[0046] In summary, when the stock solution sulfonated CS 2 CS 2 The loss is reduced by 4.8kg / T silk; when the loss of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com