Preparation method of antibacterial and antistatic polyester fabric

A polyester fabric, antistatic technology, applied in the field of preparation of antibacterial and antistatic polyester fabric, can solve the problems of lack of hydrophilic structure between molecules, low moisture regain, uncomfortable wearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

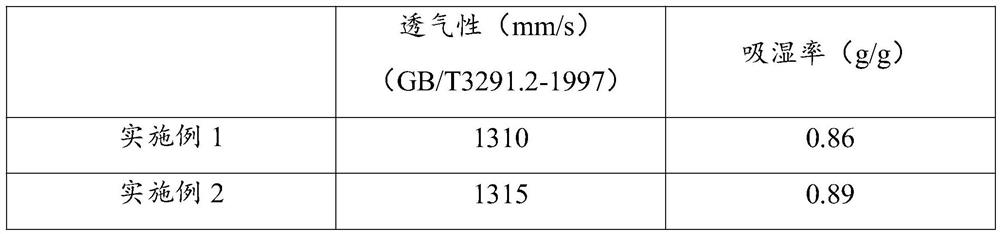

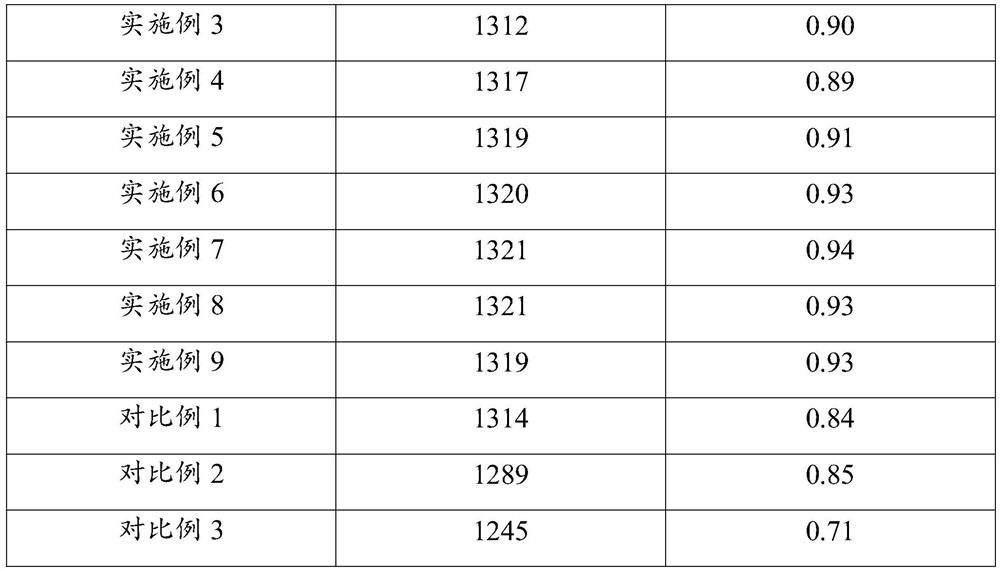

Examples

Embodiment 1

[0020] A kind of preparation method of antibacterial antistatic polyester fabric, comprises the following steps:

[0021] (1) Pretreatment: first mix 30g of antibacterial agent, 10g of titanate coupling agent, 6g of crosslinking agent, 10g of dispersant, and 40g of water-soluble polymer. Preferably, the antibacterial agent is tetrapod zinc oxide The mixture between whiskers and polyhexamethylene biguanide, the mass ratio between the tetraacicular zinc oxide whiskers and polyhexamethylene biguanide is 1.2:1, and the crosslinking agent is hydroxyethyl acrylate, diacetone The mixture between acrylamide and hydroxyethyl methacrylate, the mass ratio between the hydroxyethyl acrylate, diacetone acrylamide and hydroxyethyl methacrylate is 0.7:1.3:1, and the dispersant is ten A mixture of sodium dialkyl sulfate, sodium tripolyphosphate and sodium pyrophosphate, the mass ratio between sodium lauryl sulfate, sodium tripolyphosphate and sodium pyrophosphate is 1.1:0.8:1, the The water-s...

Embodiment 2

[0025] A kind of preparation method of antibacterial antistatic polyester fabric, comprises the following steps:

[0026] (2) Pretreatment: first mix 50g of antibacterial agent, 30g of titanate coupling agent, 8g of crosslinking agent, 30g of dispersant, and 60g of water-soluble polymer. Preferably, the antibacterial agent is tetrapod zinc oxide The mixture between whiskers and polyhexamethylene biguanide, the mass ratio between the tetraacicular zinc oxide whiskers and polyhexamethylene biguanide is 1.2:1, and the crosslinking agent is hydroxyethyl acrylate, diacetone The mixture between acrylamide and hydroxyethyl methacrylate, the mass ratio between the hydroxyethyl acrylate, diacetone acrylamide and hydroxyethyl methacrylate is 0.9:1.5:1, and the dispersant is ten A mixture of sodium dialkyl sulfate, sodium tripolyphosphate and sodium pyrophosphate, the mass ratio between sodium lauryl sulfate, sodium tripolyphosphate and sodium pyrophosphate is 1.3:1:1, the The water-sol...

Embodiment 3

[0030] A kind of preparation method of antibacterial antistatic polyester fabric, comprises the following steps:

[0031] (1) Pretreatment: first, mix 35g of antibacterial agent, 15g of titanate coupling agent, 6.5g of crosslinking agent, 15g of dispersant, and 45g of water-soluble polymer. Preferably, the antibacterial agent is a four-acicular oxidation A mixture between zinc whiskers and polyhexamethylene biguanide, the mass ratio between the tetraacicular zinc oxide whiskers and polyhexamethylene biguanide is 1.2:1, and the crosslinking agent is hydroxyethyl acrylate, bis A mixture between acetone acrylamide and hydroxyethyl methacrylate, the mass ratio between the hydroxyethyl acrylate, diacetone acrylamide and hydroxyethyl methacrylate is 0.8:1.4:1, and the dispersant is A mixture of sodium lauryl sulfate, sodium tripolyphosphate and sodium pyrophosphate, the mass ratio between sodium lauryl sulfate, sodium tripolyphosphate and sodium pyrophosphate is 1.2:0.9:1, so Said ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com