Colon-targeted gel microsphere with controllable core-shell ratio, and preparation and application of colon-targeted gel microsphere

A gel microsphere and colon-targeting technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, microcapsules, etc., can solve uncontrollable core-shell ratio, limited application, cumbersome operation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

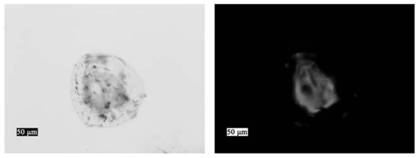

Image

Examples

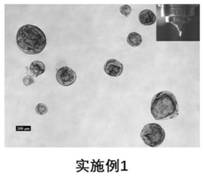

Embodiment 1

[0057] Example 1 Preparation of colon targeting gel microspheres with controlled core-shell ratio loaded with alcohol-soluble capsaicin (core-shell ratio is 0.60)

[0058] (1) 1g chitosan powder, 3g calcium chloride, 3g Tween 20 are dissolved in 94mL 2% (v / v) acetic acid aqueous solution under 600rpm stirring condition, obtain shell layer solution; 1.5g low-ester pectin Powder and 1.5g of sodium alginate powder were dissolved in 97mL of third-grade water under 600rpm stirring and 200W ultrasonic conditions to obtain an inner shell solution; 0.075g capsaicin powder and 0.05g zein powder were vortexed and 200W ultrasonic Dissolve in 4.6mL80% (v / v) ethanol aqueous solution under the condition to obtain the nuclear layer solution;

[0059] (2) Set the coaxial electrostatic spray parameters as follows for preparation: the voltage is 11kV, the injection rate of the inner shell layer is 1.5mL / h, the injection rate of the core layer is 0.5mL / h, the coaxial electrostatic spray nozzle a...

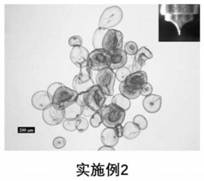

Embodiment 2

[0062] Example 2 Preparation of colon-targeted gel microspheres with a controllable core-shell ratio loaded with alcohol-soluble curcumin (the core-shell ratio is 0.58)

[0063] (1) 1g chitosan powder, 2g calcium chloride, 3g Tween 20 are dissolved in 94mL 2% (v / v) acetic acid aqueous solution under 600rpm stirring condition, obtain shell layer solution; 2g sodium alginate powder is in 600rpm stirring and 200W ultrasonic conditions were dissolved in 97mL of three-grade water to obtain the inner shell solution; 0.05g curcumin powder and 0.15g zein powder were dissolved in 4.6mL 80% ( v / v) in an aqueous ethanol solution to obtain a nuclear layer solution;

[0064] (2) Set the coaxial electrostatic spray parameters as follows to prepare: the voltage is 14kV, the injection rate of the inner shell layer is 2mL / h, the injection rate of the nuclear layer is 0.5mL / h, the coaxial electrostatic spray nozzle and the surface of the outer shell solution The distance is 120mm, the temperat...

Embodiment 3

[0067] Example 3 Preparation of colon-targeting gel microspheres loaded with water-soluble oleuropein with a controllable core-shell ratio (core-shell ratio is 0.86)

[0068] (1) 2g chitosan powder, 1g calcium chloride, 1g Tween 20 are dissolved in 94mL 2% (v / v) acetic acid aqueous solution under 600rpm stirring condition, obtain shell layer solution; 4g low-ester pectin powder Dissolve in 97mL of tertiary water under 600rpm stirring and 200W ultrasonic conditions to obtain the inner shell solution; dissolve 0.05g oleuropein powder and 0.15g kafirin powder in 4.6mL70% under vortex oscillation and 200W ultrasonic conditions (v / v) in acetic acid aqueous solution, obtain nuclear layer solution;

[0069] (2) Set the coaxial electrostatic spray parameters as follows for preparation: the voltage is 15kV, the injection rate of the inner shell layer is 1mL / h, the injection rate of the nuclear layer is 0.5mL / h, the coaxial electrostatic spray nozzle and the surface of the outer shell s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com