Preparation method and application of iron carbide/manganese cross-linked sodium alginate composite material

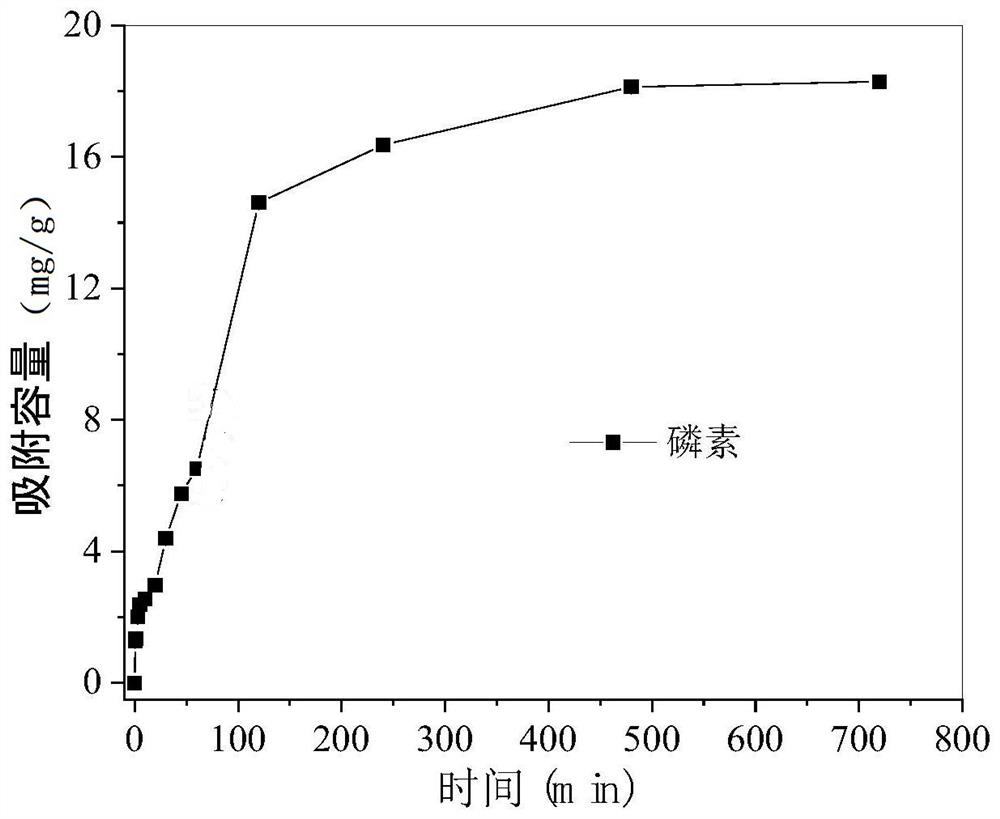

A technology of sodium alginate and composite materials, applied in the field of environmental governance, can solve the problems of low adsorption performance, high price, difficult preparation process, etc., and achieve the effect of realizing toxicity, reducing toxicity, and fast and efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a preparation method of iron carbide / manganese cross-linked sodium alginate composite material, comprising the following steps:

[0027] S1, in 2wt% sodium alginate aqueous solution, drip iron (II) salt solution and / or manganese (II) salt solution, generate iron / manganese cross-linked sodium alginate by cross-linking reaction, wash and collect microspherical particles, and dry;

[0028] S2. After sintering and carbonizing the dried sodium alginate in step S1 at 300-900°C for 1-4h under protective gas, cooling, washing, drying, grinding, and sieving to obtain the iron carbide / manganese cross-linked alginic acid Sodium composite.

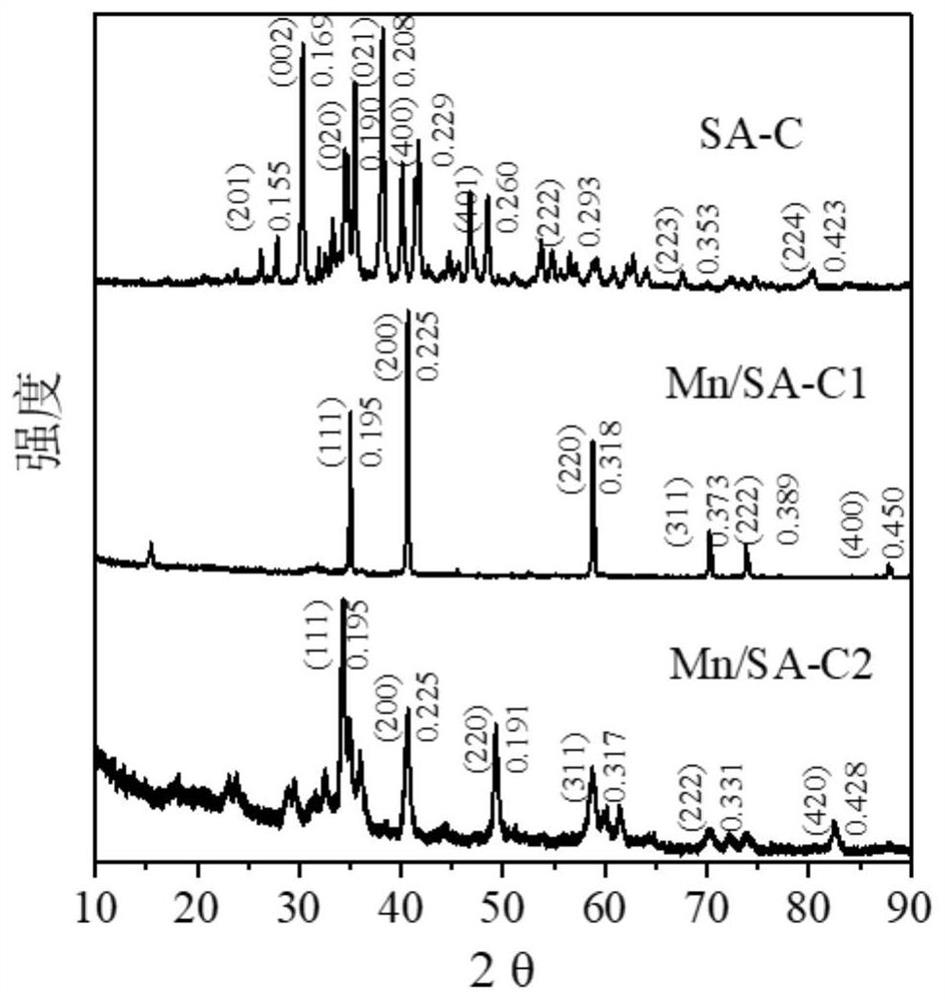

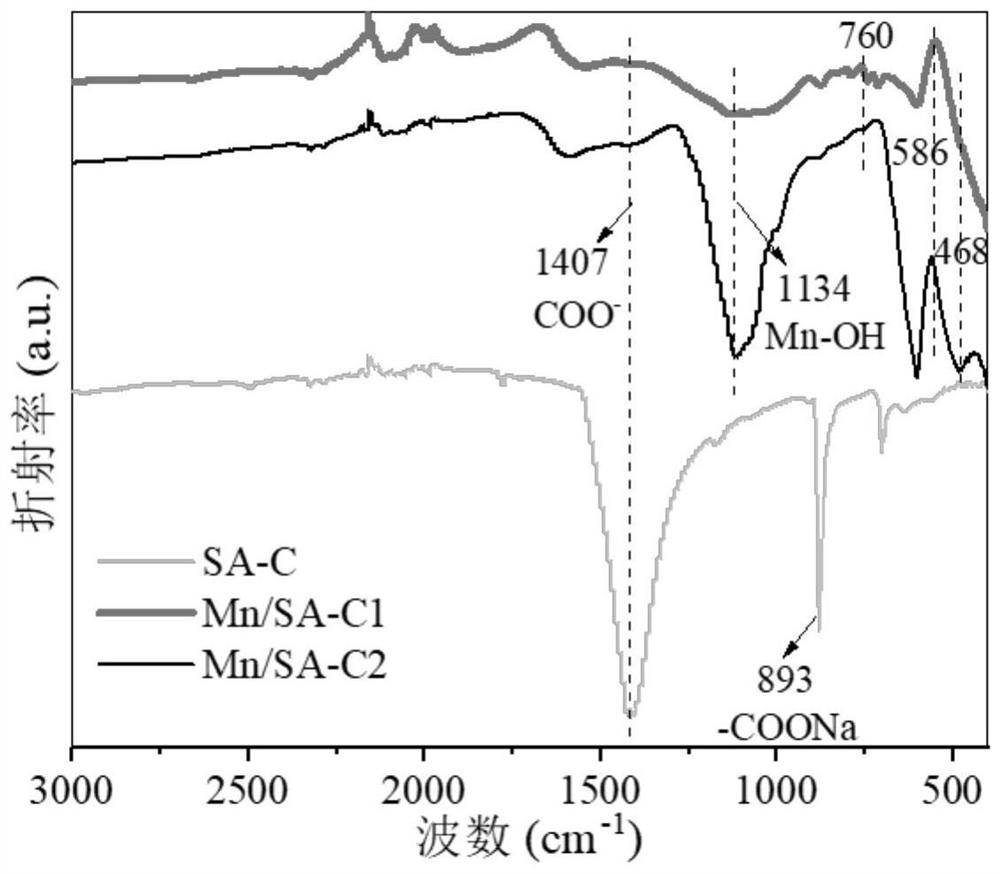

[0029] In the above technical scheme, the iron / manganese cross-linked sodium alginate obtained through step S1 is in the form of microspherical particles, which is not conducive to effective combination with heavy metal ions due to its smooth surface. The sintering and carbonization treatment o...

Embodiment 1

[0042] Dissolve 3g of sodium alginate in 150mL of distilled water at 60°C (a drop of acetic acid solution can be added dropwise during the dissolution process to assist the dissolution of sodium alginate). At the same time configure 100mmol 150mL MnSO 4 The solution was fully stirred for 2h, and the configured 2wt% sodium alginate solution was added dropwise to the MnSO 4 In solution, microspherical particles are rapidly formed. The prepared microspherical particles were washed three times with deionized water, dried in an oven at 80° C., and the microspherical particles were collected.

[0043] Place the obtained microspherical particles in a porcelain crucible, react in a vacuum muffle furnace filled with nitrogen at 600°C for 2 hours, cool to room temperature, grind the microspherical composite carbonized particles with an agate mortar, and ball mill at a speed of 220rpm with a ball mill After 15 minutes, the recovered powder was passed through a 60-mesh sieve to obtain a...

Embodiment 2

[0045] Dissolve 3g of sodium alginate in 150mL of distilled water at 60°C (a drop of acetic acid solution can be added dropwise during the dissolution process to assist the dissolution of sodium alginate). At the same time configure 100mmol 150mL MnCl 2 The solution was fully stirred for 2h, and the configured 2wt% sodium alginate solution was added dropwise to the MnCl 2 solution, and rapidly formed microspherical particles. The prepared microspherical particles were washed three times with deionized water, dried in an oven at 80° C., and the microspherical particles were collected.

[0046]Place the obtained microspherical particles in a porcelain crucible, react in a vacuum muffle furnace filled with nitrogen at 600°C for 2 hours, cool to room temperature, grind the microspherical composite carbonized particles with an agate mortar, and ball mill at a speed of 220rpm with a ball mill After 15 minutes, the recovered powder was passed through a 60-mesh sieve to obtain a man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com