Slow-release fertilizer for oilseed rape and preparation method of slow-release fertilizer

A slow-release fertilizer, rapeseed technology, applied in the application, nitrogen fertilizer, potash fertilizer and other directions, can solve the problems of not energy saving and environmental protection, low fertilizer efficiency and utilization rate, etc., and achieve the effect of alleviating diseases and insect pests, fully utilizing and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

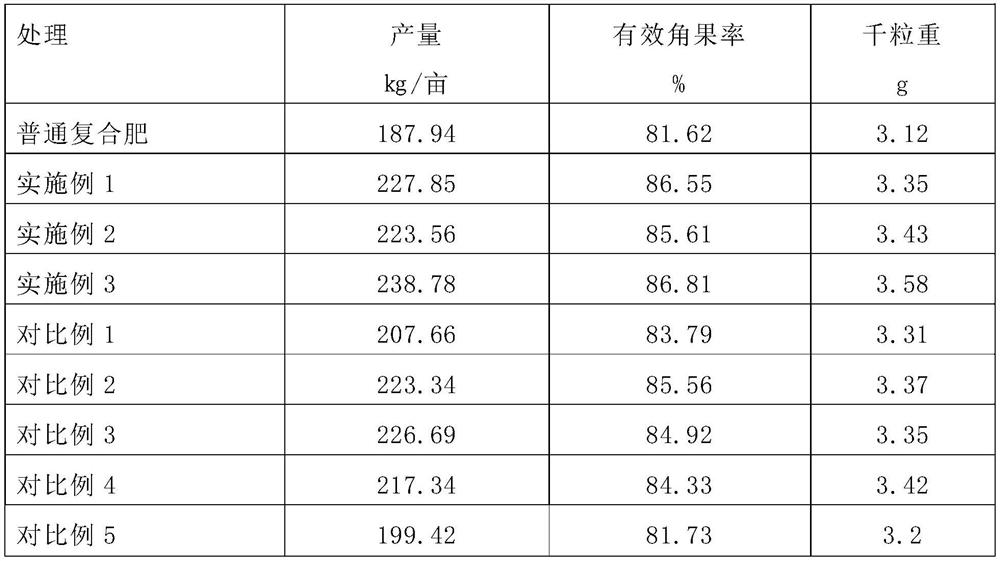

Embodiment 1

[0030] A slow-release fertilizer for rape, consisting of 370 kg of urea, 155 kg of monoammonium phosphate, 25 kg of potassium chloride, 265 kg of potassium sulfate, 27 kg of magnesium sulfate, 8 kg of zinc sulfate, 2 kg of ferrous sulfate, molybdic acid 1 kg of ammonium, 23 kg of boric acid, 8 kg of polyglutamic acid, 6 kg of brown rot potassium, 0.01 kg of smart Cong, 0.01 kg of probiotics, 108 kg of calcium carbonate powder and 2 kg of urease inhibitor.

[0031] Potassium brown humic acid is preferably produced by Xinjiang Shuanglong Humic Acid Co., Ltd. It is processed from natural mineral source humic acid and contains both large molecular weight brown black humic acid and small molecular weight fulvic acid.

[0032] Polyglutamic acid is produced by Nanjing Xuankai Biotechnology Co., Ltd. It is an ecological fertilizer additive made by microbial fermentation. After adding, the utilization rate of synergistic fertilizer can be increased from 30-35% to 40-50%. The utilization...

Embodiment 2

[0038] A slow-release fertilizer for rape, consisting of 395 kg of urea, 130 kg of monoammonium phosphate, 40 kg of potassium chloride, 247 kg of potassium sulfate, 21 kg of magnesium sulfate, 6 kg of zinc sulfate, 6 kg of ferrous sulfate, molybdic acid 1 kg of ammonium, 15 kg of boric acid, 7 kg of polyglutamic acid, 7 kg of brown rot potassium, 0.02 kg of smart Cong, 0.01 kg of probiotics, 123 kg of calcium powder, and 2 kg of urease inhibitor.

[0039]The specific production process is as follows: Mix 2 kg of urease inhibitor and 395 kg of urea evenly, and transport them to reactor A through a conveyor belt, mix with 247 kg of potassium sulfate, 40 kg of potassium chloride, 130 kg of monoammonium phosphate, and mix and heat with the system return material. , the stirring speed is 130 rpm, the temperature is 115-118°C, and the stirring time is 3 minutes; 7 kg of polyglutamic acid, 21 kg of magnesium sulfate, 6 kg of zinc sulfate, 15 kg of boric acid, and 6 kg of ferrous sulfa...

Embodiment 3

[0041] A slow-release fertilizer for rape, consisting of urea 385Kg, monoammonium phosphate 146Kg, potassium chloride 30Kg, potassium sulfate 255Kg, magnesium sulfate 25Kg, zinc sulfate 7Kg, ferrous sulfate 4Kg, ammonium molybdate 1Kg, boric acid 20Kg, poly Glutamic acid 10Kg, brown yellow rot potassium 10Kg, Zhizhicong 0.01Kg, biopromoting hormone 0.015Kg, calcium powder 105Kg, urease inhibitor 2Kg.

[0042] The specific production process is as follows: Mix 2 kg of urease inhibitor and 385 kg of urea evenly, transport them to reactor A through a conveyor belt, mix with 255 kg of potassium sulfate, 30 kg of potassium chloride, 146 kg of monoammonium phosphate, and mix and heat the mixture with the system return material. , the stirring speed is 130 rpm, the temperature is 115-118°C, and the stirring time is 3 minutes; 10 kg of polyglutamic acid, 25 kg of magnesium sulfate, 7 kg of zinc sulfate, 20 kg of boric acid, and 4 kg of ferrous sulfate , 1 kg of ammonium molybdate was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com