Lithium resource recovery method for waste batteries based on solid electrolyte

A solid electrolyte and waste battery technology, which is applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve the problems of high impurities, high energy consumption in high temperature treatment, slow kinetic rate, etc., and achieve high-purity lithium resource recovery , improve lithium recovery efficiency, and compensate for cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

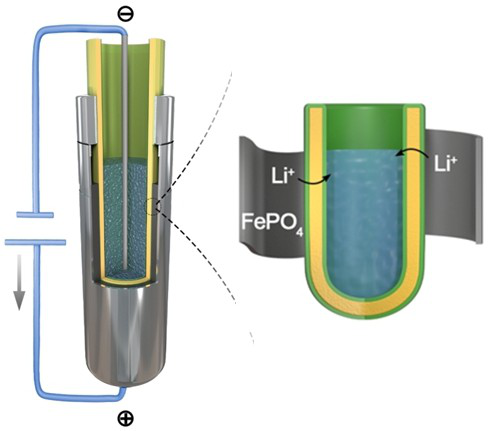

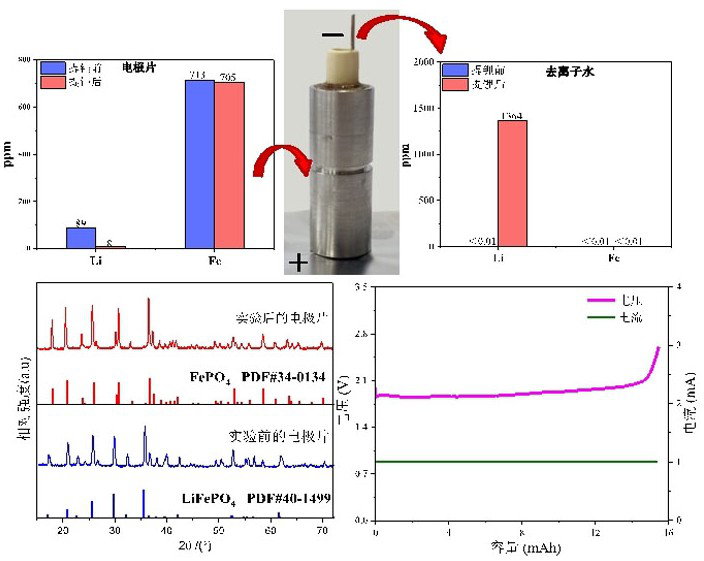

[0023] like figure 1 As shown, the solid electrolyte-based lithium resource recovery method for used batteries in this embodiment, the specific steps of the method are as follows:

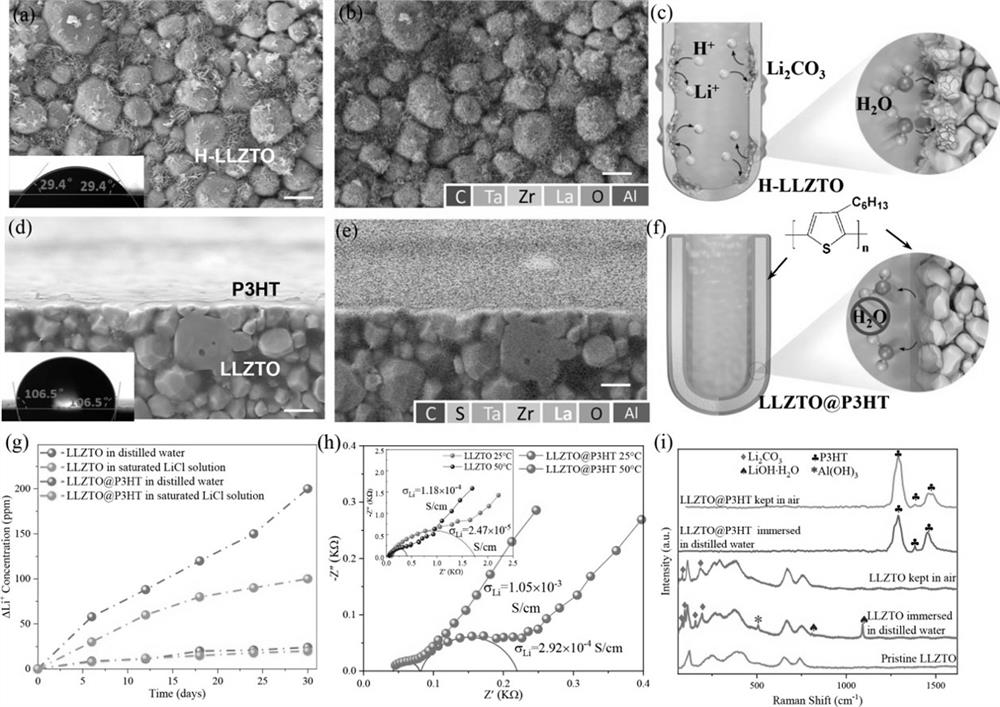

[0024] S1. Preparation of LLZTO waterproof ceramic tube: in a fume hood, dissolve a certain mass of P3HT powder in a carbon disulfide solution, wherein the ratio of P3HT powder to carbon disulfide solution is 12mg / ml, seal and stir to make a modified solution, and then mix LLZTO The ceramic tube is soaked in the modified solution for 5 minutes, and the soaked LLZTO ceramic tube is placed in a vacuum drying oven for drying. After drying, the surface of the LLZTO will form a waterproof coating;

[0025] S2, in the glove box, the electrode sheet of the taken out waste battery is wetted by lithium ion electrolyte, and the lithium ion electrolyte is 1M lithium hexafluorophosphate dissolved in ethylene carbonate with a volume ratio of 1:1, Mixed in diethyl carbonate;

[0026] S3. In the glove box, the ...

Embodiment 2

[0033] The solid electrolyte-based lithium resource recovery method for used batteries of the present embodiment, the specific steps of the method are as follows:

[0034] S1. Preparation of LLZTO waterproof ceramic tube: in a fume hood, dissolve a certain mass of P3HT powder in chloroform solution, in which the ratio of P3HT powder to chloroform solution is 22mg / ml, seal and stir to make a modified solution, and then mix LLZTO The ceramic tube is soaked in the modified solution for 5 minutes, and the soaked LLZTO ceramic tube is placed in a vacuum drying oven for drying. After drying, the surface of the LLZTO will form a waterproof coating;

[0035] S2, in the glove box, the electrode sheet of the taken out waste battery is wetted by lithium ion electrolyte, and the lithium ion electrolyte is 1M lithium hexafluorophosphate dissolved in ethylene carbonate with a volume ratio of 1:1, Mixed in diethyl carbonate;

[0036] S3. In the glove box, the wetted electrode sheet prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com