Short-process spinning method for polyester industrial yarns

An industrial yarn and short-process technology, which is applied in the field of polyester industrial yarn, can solve the problems of increasing heterogeneous structure, unfavorable strength and modulus, and increasing the size of amorphous region, so as to reduce the number of thermal stretching series and magnification, Effect of reducing microstructural defects, reduction of tensile series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

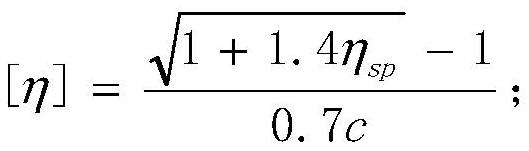

[0034] The preparation method of the polytetrafluoroethylene nano-particle containing ester group on the surface is as follows:

[0035] Configuration methacrylate volume content is 37.5% chlorobenzene solution, polytetrafluoroethylene nano-powder (polymerization degree is 5 * 10 3 , with an average particle diameter of 300nm) placed in the aforementioned solution (the mass ratio of polytetrafluoroethylene nano-powder to the aforementioned solution is 1:2), and treated with plasma in an argon atmosphere for 100 s to make formazan The chemical graft polymerization of acrylate on the surface of polytetrafluoroethylene nano powders forms a layer of graft polymer on the surface, and obtains a polytetrafluoroethylene with an average particle size of 300nm and an ester group content of 20ppm. Tetrafluoroethylene nanoparticles.

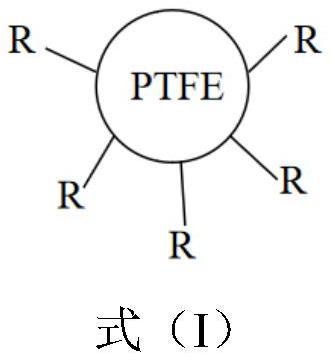

[0036] The structural formula of the polytetrafluoroethylene nanoparticles containing ester groups on the surface is as formula (I), wherein,

Embodiment 2

[0038] The preparation method of the polytetrafluoroethylene nano-particle containing ester group on the surface is as follows:

[0039] Configuration ethyl methacrylate volume content is the chlorobenzene solution of 37.5%, polytetrafluoroethylene nano-powder (polymerization degree is 5 * 10 3 , with an average particle diameter of 350nm) placed in the aforementioned solution (the mass ratio of polytetrafluoroethylene nano-powder to the aforementioned solution is 1:2), and treated with plasma in an argon atmosphere for 150s to make formazan Ethyl acrylate undergoes chemical graft polymerization on the surface of polytetrafluoroethylene nano-powders, forming a layer of graft polymer on the surface, and obtaining a surface containing ester groups with an average particle size of 350nm and an ester group content of 30ppm. PTFE nanoparticles.

[0040] The structural formula of the polytetrafluoroethylene nanoparticles containing ester groups on the surface is as formula (I), whe...

Embodiment 3

[0042] The preparation method of the polytetrafluoroethylene nano-particle containing ester group on the surface is as follows:

[0043] Configuration propyl methacrylate volume content is the chlorobenzene solution of 37.5%, polytetrafluoroethylene nano-powder (polymerization degree is 5 * 10 3 , with an average particle diameter of 400nm) placed in the aforementioned solution (the mass ratio of polytetrafluoroethylene nano-powder to the aforementioned solution is 1:2), and treated with plasma in an argon atmosphere, and the treatment time is 200s to make formazan Propyl acrylate is chemically grafted and polymerized on the surface of polytetrafluoroethylene nanopowders, forming a layer of graft polymer on the surface, and obtaining a surface containing ester groups with an average particle size of 400nm and an ester group content of 40ppm. PTFE nanoparticles.

[0044] The structural formula of the polytetrafluoroethylene nanoparticles containing ester groups on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com