Culture soil for improving survival rate of camellia chekiangoleosa seedlings and preparation method of culture soil

A technology for safflower oil camellia and survival rate, which is applied in the field of culture soil for improving the survival rate of safflower oil camellia seedlings and the field of preparation thereof, and can solve the problems such as the influence of changes in physiological indicators of camellia oleifera seedlings on the survival rate of camellia oleifera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Antibacterial particles are made by the following steps:

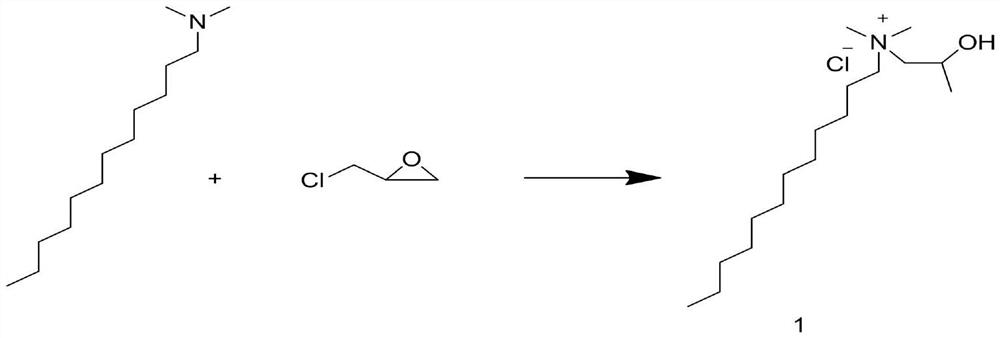

[0047] Step S1: Add 0.1 mol of dodecyl dimethyl tertiary amine and 100 mL of isopropanol into the beaker, stir for 10 minutes, then raise the temperature to 41°C, add 0.1mol of epichlorohydrin, control the reaction temperature at 70°C, and stir for 7 hours After the reaction, the isopropanol was removed by rotary evaporation under reduced pressure, cooled to room temperature, dissolved in acetone, placed in a refrigerator at 5°C for 3h, taken out, filtered with suction, and the filter cake was dried at 30°C for 12h to obtain intermediate 1 ;

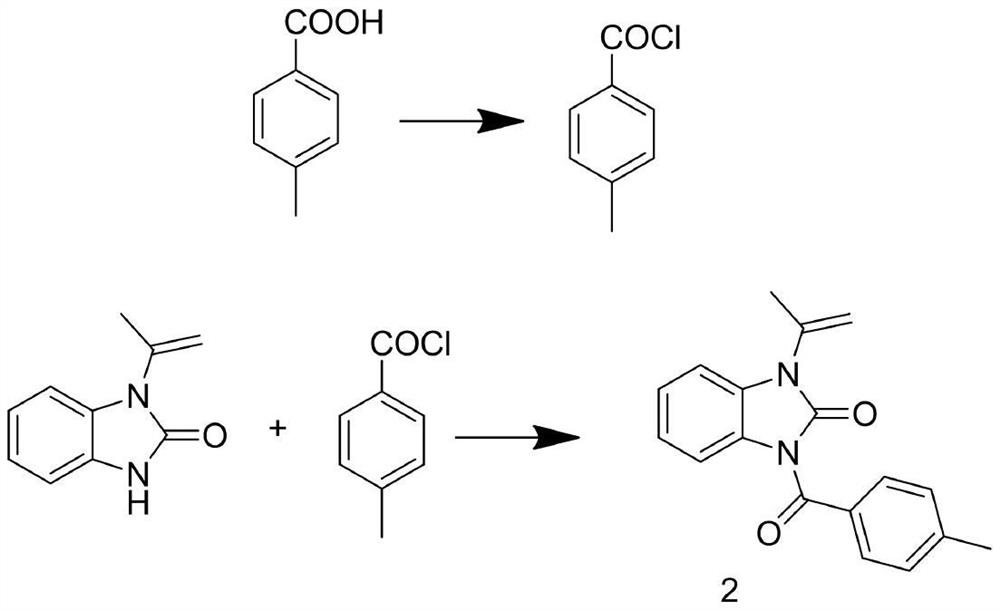

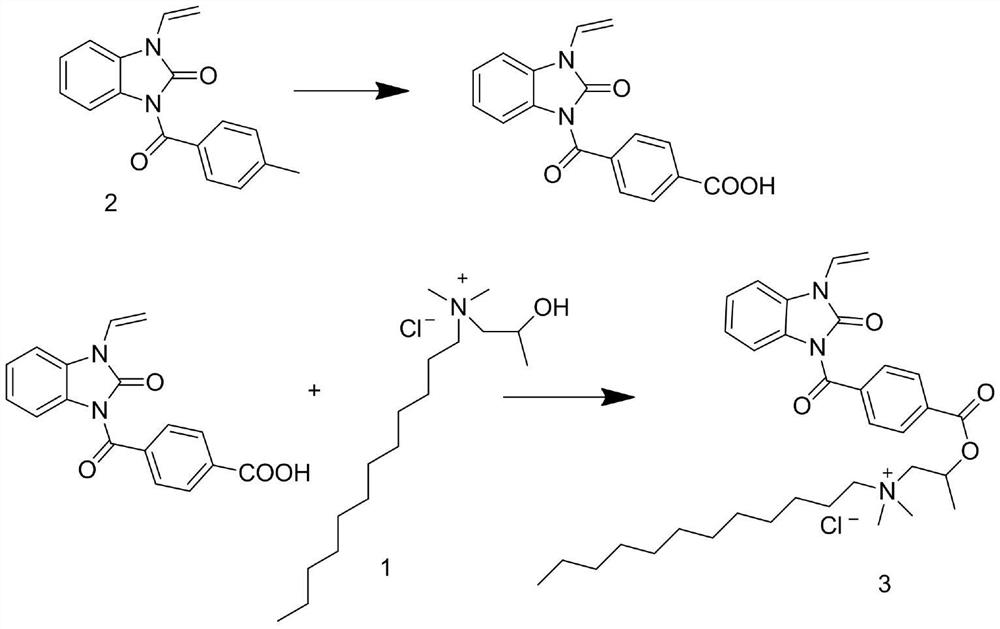

[0048] Step S2: Add 1mmol of 1-isopropenyl-2-benzimidazolone and 20mL of dried dichloromethane into a three-necked flask, stir and dissolve, add 0.3mL of triethylamine and 1mmol of p-toluic acid, and set the temperature at 0°C Add 5 mL of triphosgene solvent dropwise, and control the dropping rate at 1 drop / second. After the dropwise addition, stir and react for 2 hours a...

Embodiment 2

[0054] Antibacterial particles are made by the following steps:

[0055] Step S1: Add 0.1 mol of dodecyl dimethyl tertiary amine and 200 mL of isopropanol into a beaker, stir for 10 minutes, heat up to 45°C, add 0.1mol of epichlorohydrin, control the reaction temperature at 80°C, and stir for 7 hours After the reaction, the isopropanol was removed by rotary evaporation under reduced pressure, cooled to room temperature, dissolved in acetone, placed in a refrigerator at 5°C for 5h, taken out, filtered with suction, and the filter cake was dried at 40°C for 12h to obtain intermediate 1 ;

[0056] Step S2: Add 1mmol of 1-isopropenyl-2-benzimidazolone and 28mL of dried dichloromethane into a three-necked flask, stir and dissolve, add 0.3mL of triethylamine and 1mmol of p-toluic acid, at 5°C Add 5 mL of triphosgene solvent dropwise, and control the dropping rate at 1 drop / second. After the dropwise addition, stir and react for 2 hours at room temperature. Drying over sodium sulfa...

Embodiment 3

[0068] Water retaining agent is made by the following steps:

[0069] Mix 50g of distarch phosphate and 30mL of distilled water, gelatinize at 60°C for 20min, cool to room temperature, add 100g of potassium hydroxide neutralized acrylic acid solution to it, ultrasonically vibrate at a frequency of 20kHz for 15min, then add 0.1 g of N,N-methylenebisacrylamide, 0.15g of ammonium persulfate and 0.2g of sodium binitrophenolate, mix well, control the reaction temperature at 70°C and stir for 30min, then dry in a vacuum oven at 65°C to Constant weight, then pulverized to obtain water retaining agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com