Additive manufacturing method for thin-wall tubular component

A tubular component and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as difficulty in producing thin-walled tubular components and large-diameter tubular components, restrictions on the promotion and application of alloy material tubular components, and limitations on the size and shape of tubular components , to achieve the effects of rapid preparation, tight integration, and reduced processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

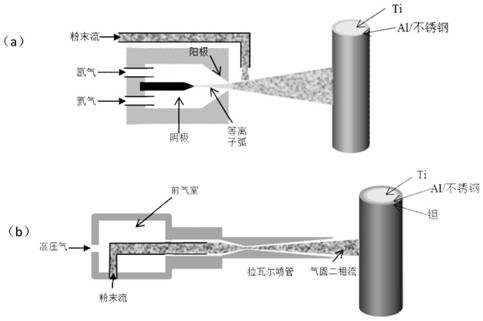

[0036] see figure 1 , a method for additive manufacturing of a thin-walled tubular member, comprising the following steps

[0037] 1) Clamp the tubular titanium substrate on the machine tool, degrease, dry and sandblast the surface of the tubular titanium substrate; the titanium substrate in step 1) adopts a hollow tube with a diameter of 3mm, and the sandblasting equipment uses supersonic Air flame spraying (HVAF) equipment, the air pressure during sandblasting is 60PSI, the propane pressure is 50PSI, the sandblasting distance is 250mm, and the sandblasting rate is 80g / min.

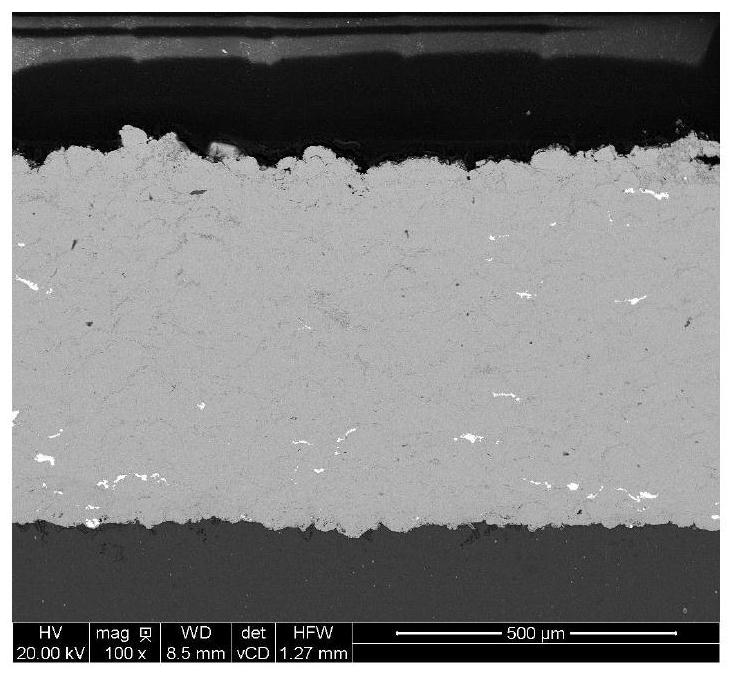

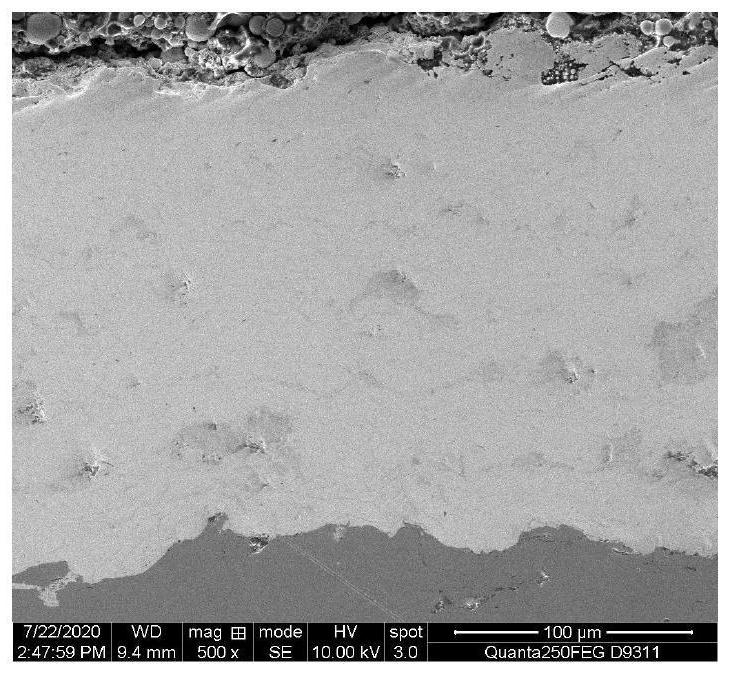

[0038] 2) preparing an aluminum / stainless steel composite coating on the outer wall of the titanium substrate in step 1), forming a titanium-aluminum / stainless steel composite pipe substrate; step 2) adopting the aluminum / stainless steel composite powder spraying method when preparing the aluminum / stainless steel composite coating, The aluminum / Cr25 stainless steel composite powder is loaded into the pl...

Embodiment 2

[0051] A method for additive manufacturing of thin-walled tubular components, comprising the following steps

[0052] 1) Clamp the tubular titanium substrate on the machine tool, degrease, dry and sandblast the surface of the tubular titanium substrate; the titanium substrate in step 1) adopts a hollow tube with a diameter of 10mm, and the sandblasting equipment uses supersonic air For flame spraying (HVAF) equipment, the air pressure during sandblasting is 70PSI, the propane pressure is 60PSI, the sandblasting distance is 300mm, and the sandblasting rate is 100g / min.

[0053] 2) preparing an aluminum / stainless steel composite coating on the outer wall of the titanium substrate in step 1), forming a titanium-aluminum / stainless steel composite pipe substrate; step 2) adopting the aluminum / stainless steel composite powder spraying method when preparing the aluminum / stainless steel composite coating, The aluminum / Cr25 stainless steel composite powder is loaded into the plasma pow...

Embodiment 3

[0061] A method for additive manufacturing of thin-walled tubular components, comprising the following steps

[0062] 1) Clamp the tubular titanium substrate with a diameter of 30 mm on the machine tool, and perform degreasing, drying and sandblasting on the surface of the tubular titanium substrate; the titanium substrate in step 1) adopts a hollow tube, and the sandblasting equipment uses supersonic air For flame spraying (HVAF) equipment, the air pressure during sandblasting is 80PSI, the propane pressure is 70PSI, the sandblasting distance is 200mm, and the sandblasting rate is 200g / min.

[0063] 2) preparing an aluminum / stainless steel composite coating on the outer wall of the titanium substrate in step 1), forming a titanium-aluminum / stainless steel composite pipe substrate; step 2) adopting the aluminum / stainless steel composite powder spraying method when preparing the aluminum / stainless steel composite coating, Specifically, plasma spraying equipment is used, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com