Method for preparing biomass carbon-loaded molybdenum sulfide electrode material by one-step method

A biomass carbon and electrode material technology, which is applied in the preparation/purification of molybdenum sulfide and carbon, electrodes, etc., can solve the problems of unsuitability for industrial production and low hydrogen production efficiency of electrolyzed water, and achieve excellent hydrogen evolution performance of electrolyzed water, excellent Electrochemical performance, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

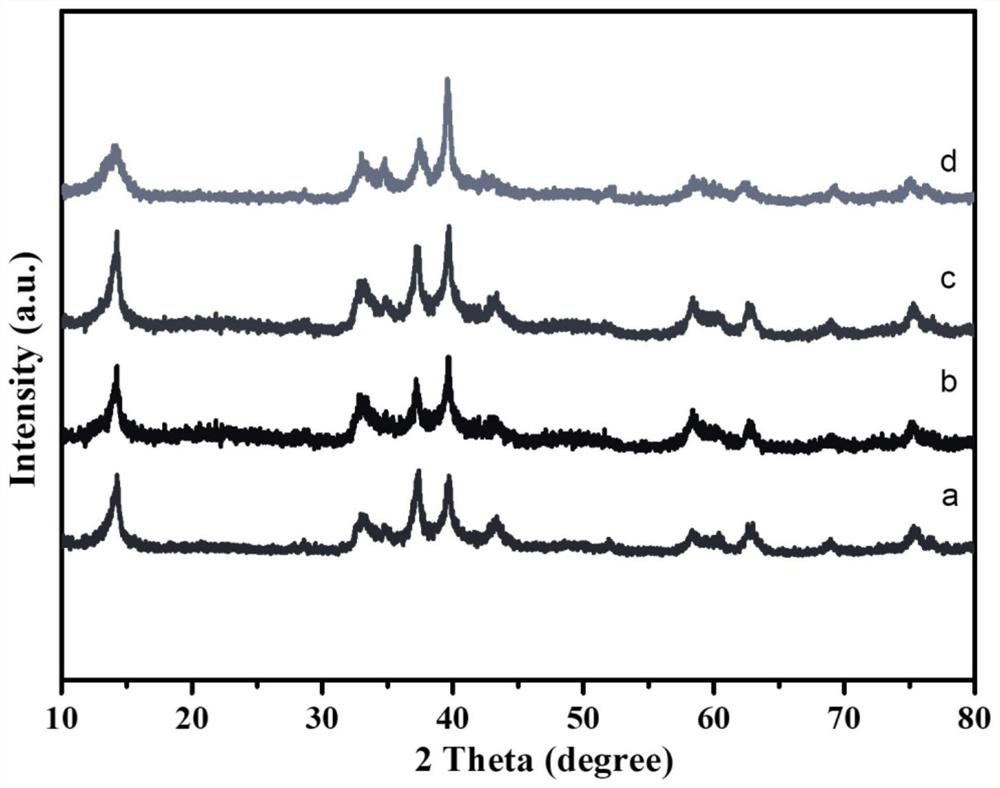

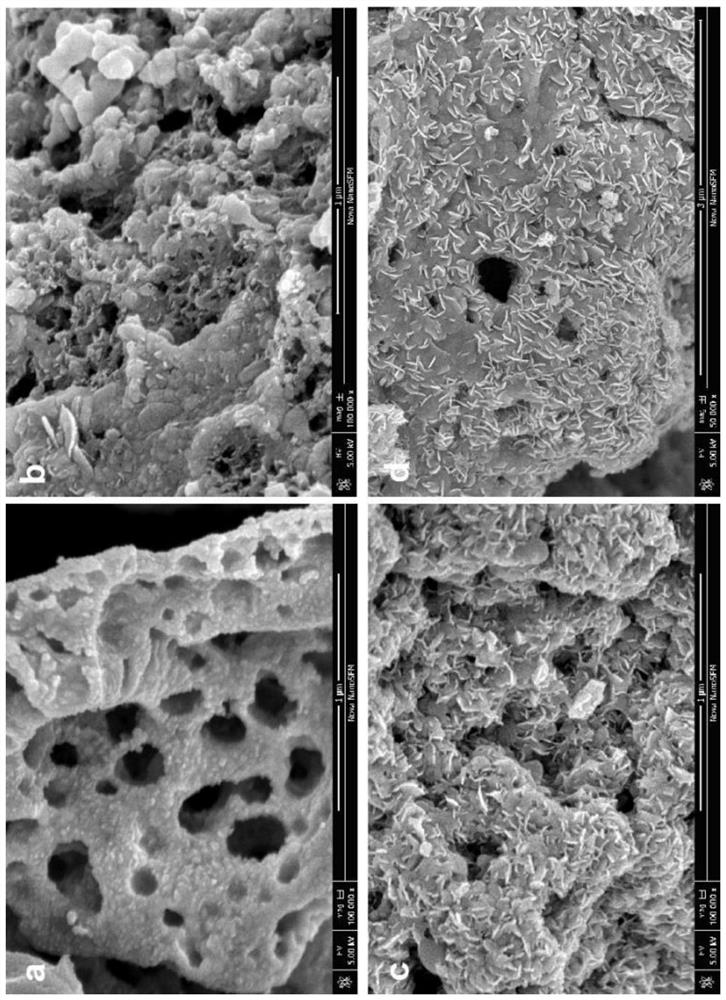

[0031] Dissolve 1 g of lotus pollen and 2 g of ammonium nitrate in 12 mL of deionized water, and ultrasonicate at room temperature for 5 h. Then add 0.37g of ammonium molybdate to dissolve in the above mixture, and then ultrasonic treatment for 1h, vacuum drying at 60°C for 24h to obtain powder solid. Put the dried powder sample in a porcelain boat and put it in the downstream of the dual-temperature tube furnace in a nitrogen atmosphere, and weigh 0.5g of sublimed sulfur and put it in another porcelain boat and put it in the upstream of the dual-temperature tube furnace. The upstream and downstream calcination temperature is 500°C (heating rate 2.5°C min -1 ) and 900°C (heating rate 5°C min -1 ), calcined for 1h. After cooling to room temperature, a solid powder was obtained. XRD patterns such as figure 1 As shown in a, the XRD curve conforms to the XRD standard card of molybdenum sulfide (PDF#37-1492), indicating that the biomass carbon-supported molybdenum sulfide was s...

Embodiment 2

[0033] Dissolve 1 g of lotus pollen and 2 g of ammonium nitrate in 12 mL of deionized water, and ultrasonicate at room temperature for 5 h. Then add 0.37g of ammonium molybdate to dissolve in the above mixture, and then ultrasonic treatment for 1h, vacuum drying at 60°C for 24h to obtain powder solid. Put the dried powder sample in a porcelain boat and place it downstream of a dual-temperature tube furnace in a nitrogen atmosphere, and weigh another 1g of sublimed sulfur, put it in another porcelain boat and place it upstream of the dual-temperature tube furnace, and set it on the tube furnace respectively. The downstream calcination temperature is at 500°C (heating rate 2.5°C min -1 ) and 900°C (heating rate 5°C min -1 ), calcined for 1h. After cooling to room temperature, a solid powder was obtained. XRD patterns such as figure 1 As shown in b, the XRD curve conforms to the XRD standard card of molybdenum sulfide (PDF#37-1492), indicating that the biomass carbon-loaded m...

Embodiment 3

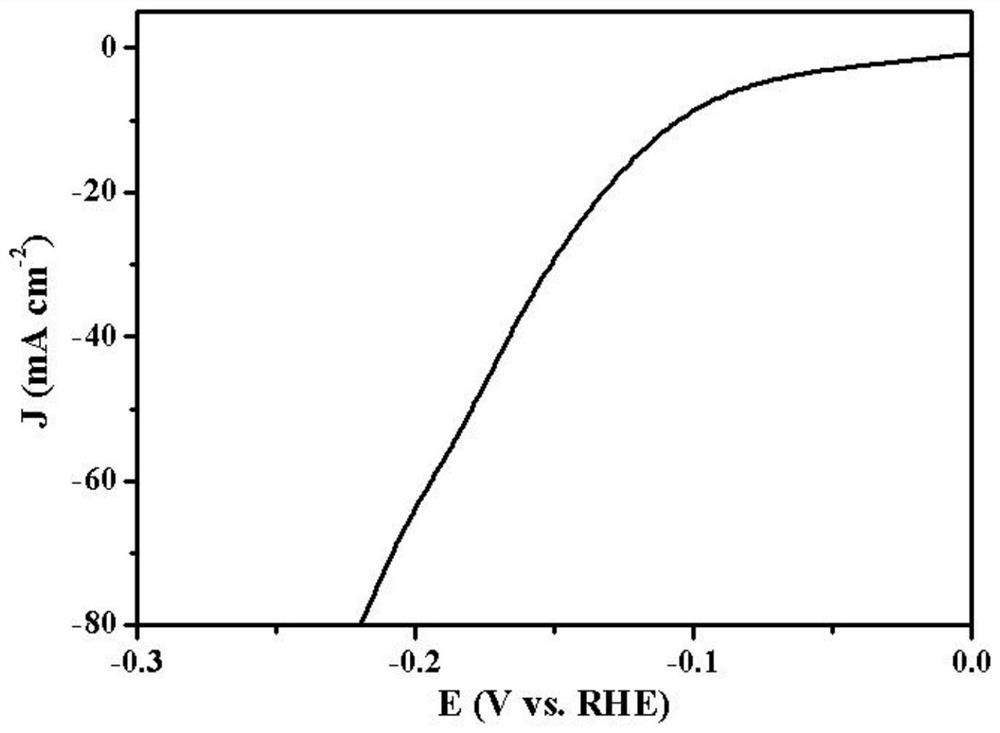

[0035] Dissolve 1 g of lotus pollen and 2 g of ammonium nitrate in 12 mL of deionized water, and ultrasonicate at room temperature for 5 h. Then add 0.37g of ammonium molybdate to dissolve in the above mixture, and then ultrasonic treatment for 1h, vacuum drying at 60°C for 24h to obtain powder solid. Put the dried powder sample in a porcelain boat and put it in the downstream of the dual-temperature tube furnace in a nitrogen atmosphere, and weigh 2g of sublimed sulfur in another porcelain boat and put it in the upstream of the dual-temperature tube furnace. The downstream calcination temperature is at 500°C (heating rate 2.5°C min -1 ) and 900°C (heating rate 5°C min -1 ), calcined for 1h. After cooling to room temperature, a solid powder was obtained. XRD patterns such as figure 1 As shown in c, the XRD curve conforms to the XRD standard card (PDF#37-1492) of molybdenum sulfide, indicating that the biomass carbon-loaded molybdenum sulfide was successfully prepared; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com