A semiconductor single crystal silicon growth device

A growth device and single crystal silicon technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of reducing the conductive quality, single crystal silicon rod pollution, and can not well solve the carbon pollution, etc. Improve conductivity quality, reduce rework rate, reduce conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

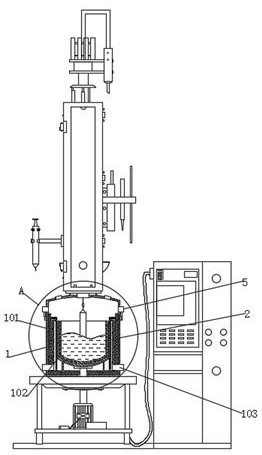

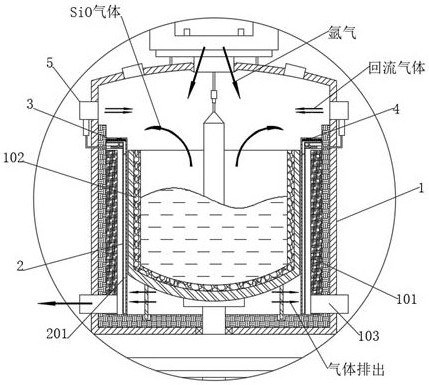

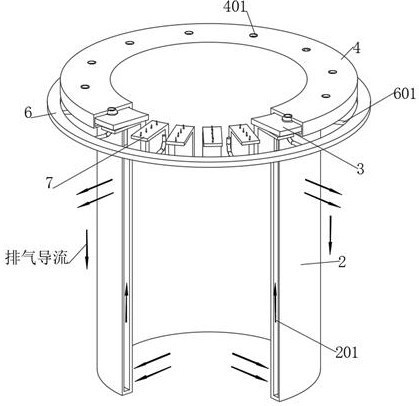

[0044] see Figure 1-10 , a semiconductor single crystal silicon growth device, comprising a single crystal silicon furnace body 1, a graphite heater 101 installed in the single crystal silicon furnace body 1 and a silicon melting crucible 102 matched with the graphite heater 101, the single crystal The silicon furnace body 1 is fixedly installed with a direction-adjusting adsorption cylinder 2 between the graphite heater 101 and the silicon melting crucible 102. The upper end of the direction-adjusting adsorption cylinder 2 is fixedly connected with a microporous one-way adsorption plate 4. An X-type zeolite molecular sieve 3 is fixedly connected to the upper inner wall of the one-way adsorption plate 4, and the inner wall of the X-type zeolite molecular sieve 3 is coated with a layer of cuprous chloride to improve its adsorption capacity for carbon monoxide gas. The microporous one-way adsorption plate 4 The inner wall is connected with an extrusion regeneration assembly 7 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com