Precious metal ion adsorption material based on magnetic metal organic framework and preparation method

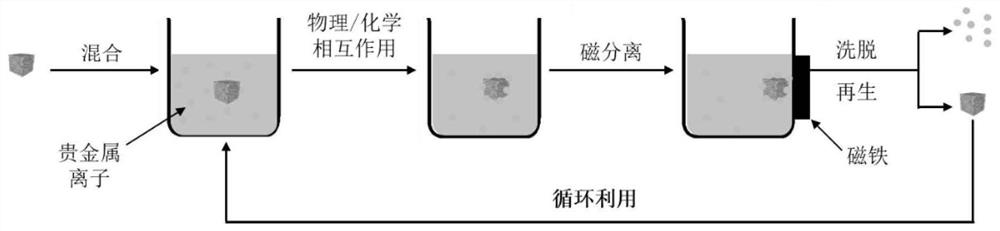

A precious metal ion, organic framework technology, applied in alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of increasing the use cost of MOFs, and achieve enhanced stability, simple recovery process, High adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

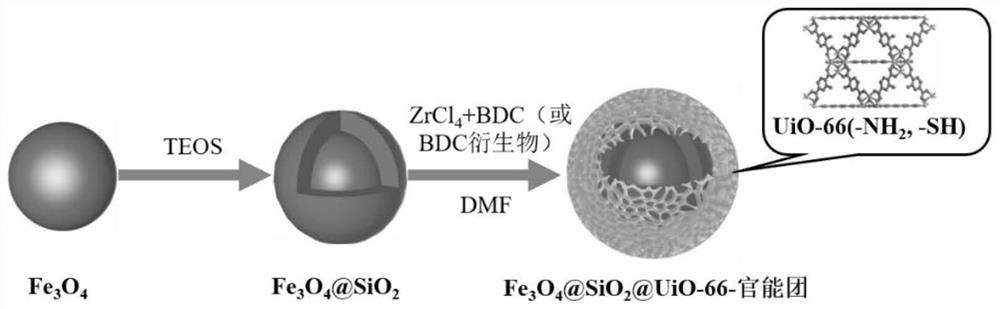

[0035] The invention provides a noble metal ion adsorption material based on a magnetic metal organic framework and a preparation method.

[0036] The central metal of the adsorption material MOFs is Zr, the organic ligand is terephthalic acid or its derivatives, and the expression is Fe 3 o 4 @SiO 2 @UiO-66 - Functional groups.

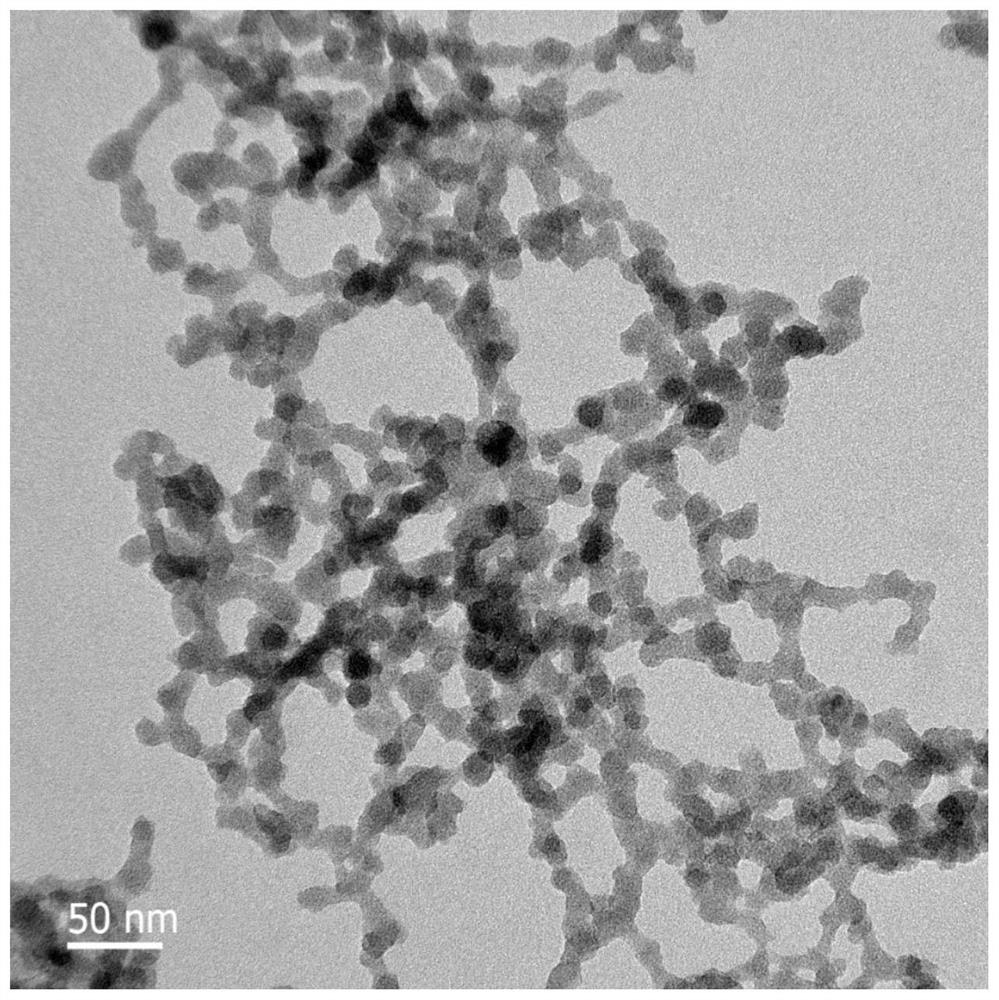

[0037] Fe in this material 3 o 4 The content is 1%~50%, and the material has magnetism, the magnetic test figure of the synthesized magnetic MOFs composite material of the present invention is as follows Figure 5 Shown; Fe 3 o 4 Coated SiO 2 , Fe 3 o 4 The particle size is 5-50nm, SiO 2 The thickness of the shell layer is 1-30 nm.

[0038] The preparation method of this adsorption material comprises steps as follows:

[0039] (1) NaHCO 3 The solution is mixed with the ferric salt solution in proportion and then reacted. After the brick-red precipitate is formed, the reducing agent solution is added dropwise to the mixture. After the bri...

Embodiment 1

[0061] 1. Magnetic Zr-based MOFs composite Fe 3 o 4 @SiO 2 The preparation steps of @UiO-66 are as follows:

[0062] (1) 0.3mol / L of FeCl 3 solution with 0.45mol / L NaHCO 3 The solution was mixed at a ratio of 1:2 and then reacted. After a brick-red precipitate was formed in the solution, 0.05mol / L vitamin C solution was added dropwise, and the mixture was transferred to a p-polyphenylene (PPL) reactor after stirring for 10 minutes. Place in a drying oven at 5°C min -1 Heating to 180°C at a rate of 12h, followed by 4°C·min -1 rate down to room temperature. Wash with ethanol and ultrapure water for 3 times and then vacuum dry for later use. The obtained product is marked as Fe 3 o 4 nanoparticles.

[0063] (2) Take 230mg Fe 3 o 4The nanoparticles were ultrasonically dispersed in 100 mL of a mixed solution of ethanol and water (ethanol: water = 1:4) for 30 min, then transferred to a three-necked round-bottomed flask and added with 1.5 mL of concentrated ammonia water. ...

Embodiment 2

[0071] 1. Amino-modified magnetic Zr-based MOFs composite Fe 3 o 4 @SiO 2 @UiO-66-NH 2 The synthesis steps are as follows:

[0072] (1) 0.3mol / L of Fe 2 (SO 4 ) 3 solution with 0.45mol / L NaHCO 3 The solution was mixed at a ratio of 1:2 and then reacted. After a brick-red precipitate was formed in the solution, 0.05mol / L uric acid solution was added dropwise. After stirring for 10 minutes, the mixture was transferred to a PPL reactor, and placed in a drying oven for 5 ℃·min -1 Heating to 180°C at a rate of 12h, followed by 4°C·min -1 The rate will come to room temperature. Wash with ethanol and ultrapure water for 3 times and then vacuum dry for later use. The obtained product is marked as Fe 3 o 4 nanoparticles.

[0073] (2) Take 230mg Fe 3 o 4 The nanoparticles were ultrasonically dispersed in 100 mL of a mixed solution of ethanol and water (ethanol: water = 1:4) for 30 min, then transferred to a three-necked round-bottomed flask and added with 1.5 mL of concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com