Preparation method of polymer adhesive for asphalt concrete

A kind of asphalt concrete and polymer technology, applied in the field of polymer adhesive preparation, can solve the problems of poor construction performance, short service life of concrete adhesive, not easy to wear, etc., and achieve the effect of good light transmission and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] see Figure 1-6 Shown, present embodiment is a kind of preparation method of polymer adhesive for asphalt concrete, comprises the following steps:

[0036] Step 1: Soak the talc powder in the acetic acid solution with a pH value of 4, perform suction filtration after 1 hour, put the filter cake in a vacuum oven, and dry it at a temperature of 90°C for 5 to obtain the talc pretreated with acetic acid pink;

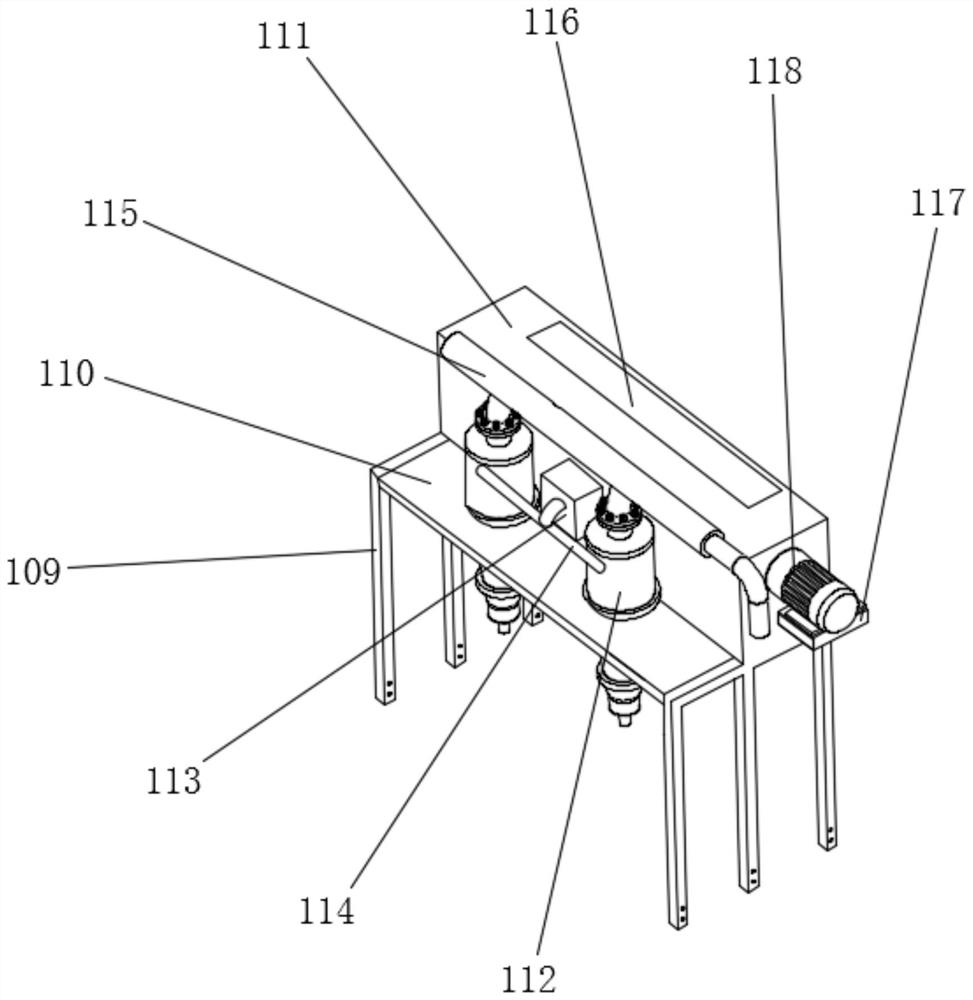

[0037] Step 2: Open the sealing cover 116 of the grinding and screening equipment, put the talcum powder pretreated by acetic acid into the inner cavity of the grinding chamber 111, and the talcum powder pretreated by acetic acid flows into the grinding tank 130 through the guide seat 129;

[0038] Step 3: start the grinding motor 127, the grinding motor 127 runs to drive the grinding disc 128 to rotate, start the drive motor 118, the drive motor 118 runs to drive the threaded rod 124 to rotate, because the threaded rod 124 is threaded with the threaded base 126, th...

Embodiment 2

[0049] see Figure 1-6 Shown, present embodiment is a kind of preparation method of polymer adhesive for asphalt concrete, comprises the following steps:

[0050] Step 1: Soak the talc powder in an acetic acid solution with a pH value of 5, perform suction filtration after 2 hours, put the filter cake in a vacuum oven, and dry it for 7 hours at a temperature of 95°C to obtain talc pretreated with acetic acid pink;

[0051] Step 2: Open the sealing cover 116 of the grinding and screening equipment, put the talcum powder pretreated by acetic acid into the inner cavity of the grinding chamber 111, and the talcum powder pretreated by acetic acid flows into the grinding tank 130 through the diversion seat 129;

[0052] Step 3: start the grinding motor 127, the grinding motor 127 runs to drive the grinding disc 128 to rotate, start the drive motor 118, the drive motor 118 runs to drive the threaded rod 124 to rotate, because the threaded rod 124 is threaded with the threaded base 1...

Embodiment 3

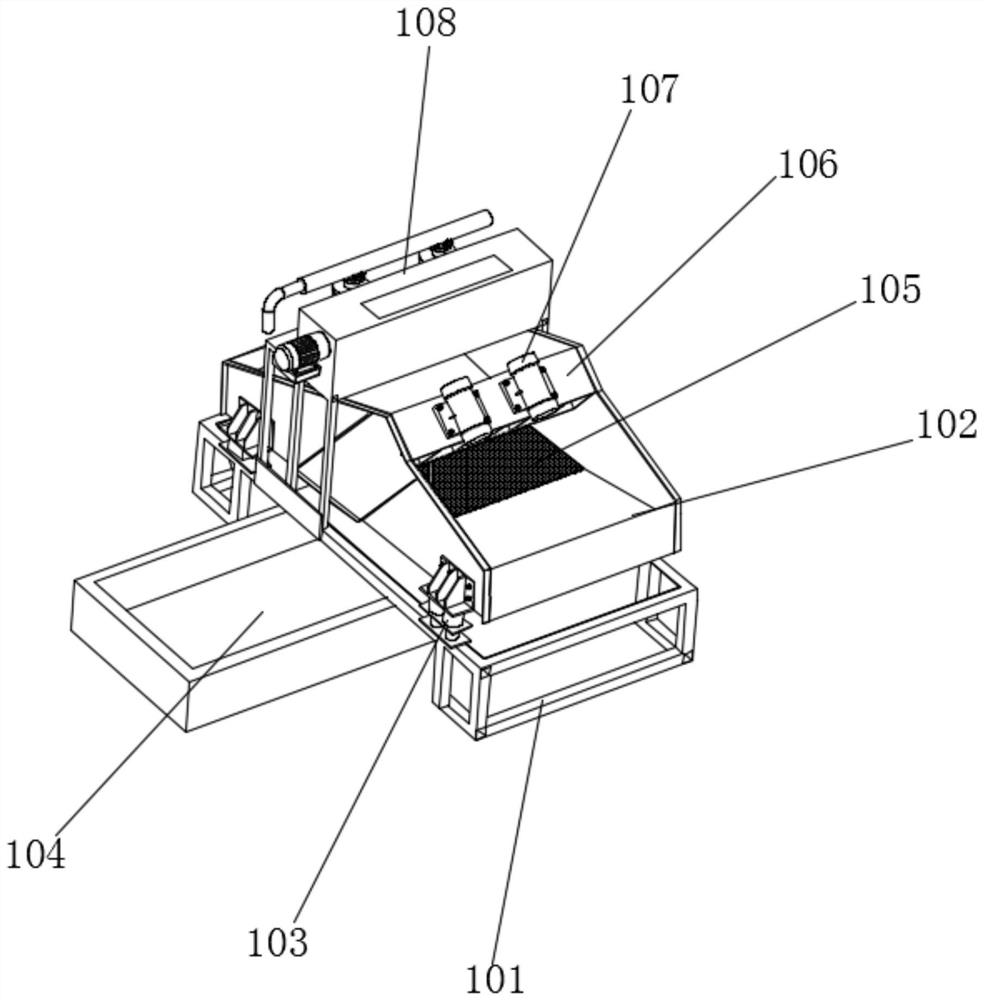

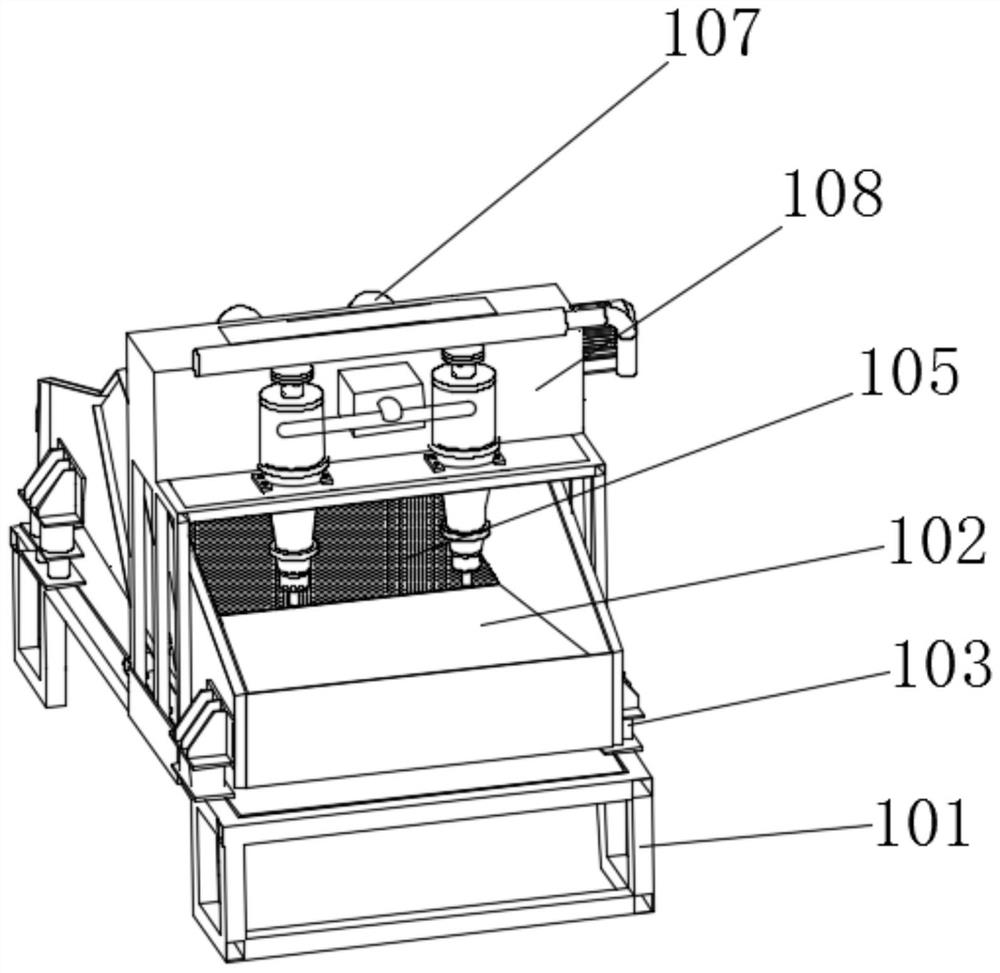

[0063]see Figure 1-6 As shown, the grinding and screening equipment in the present embodiment includes a mounting frame 101, a filter bin 102, a support leg 103, a receiving tray 104, a fine filter screen 105, a transmission plate 106, a vibrating motor 107, and a grinding mechanism 108. A filter bin 102 is arranged directly above the frame 101, and several support legs 103 are installed on both sides of the filter bin 102, and several of the support legs 103 on both sides are respectively installed on both sides of the top of the mounting frame 101, The below of described installation frame 101 is placed with collecting tray 104, and the bottom middle position of described filter bin 102 is equipped with fine filter screen 105, and described fine filter screen 105 is positioned at the top of receiving tray 104, and described filter bin 102 A drive plate 106 is installed on the top of the drive plate 106, and several vibration motors 107 are installed on the drive plate 106. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com