Preparation method and application of difunctional electrocatalyst

An electrocatalyst and dual-function technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of limited electrochemical reaction state, reduction of catalytic active sites, local charge transport limitation, etc., to avoid aggregation and desorption Attachment, the effect of accelerating charge transport efficiency and overcoming differences in surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

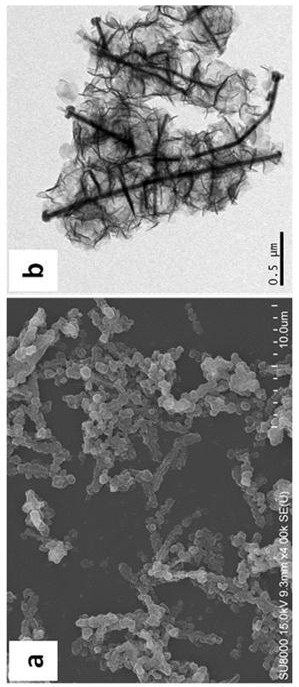

[0035] Step S1: Add 0.9g of cuprous chloride and 28g of sucrose into 35mL of deionized water, stir and mix evenly, then transfer to a 500mL polytetrafluoroethylene reactor, react at 160°C for 36h, cool to room temperature, and wash with deionized water After several times of vacuum drying, a one-dimensional conductive material carrier is obtained. The one-dimensional conductive material carrier has a skin-core structure, that is, the material of the skin layer is carbon, and the material of the inner core is copper;

[0036] Step S2: Take 10 mg of the one-dimensional conductive material carrier obtained in step S1 and add it to 40 mL of ethylene glycol, then add 1560 mg of sodium acetate, 590 mg of polyethylene glycol, 800 mg of ferric chloride hexahydrate and 900 mg of 1H-benzimidazole-5 -Carboxylic acid, stirred vigorously for 30 minutes, transferred to a 50mL polytetrafluoroethylene reactor, reacted at 170°C for 9 hours, cooled to room temperature, washed several times with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com