Degradable shape memory polymer, preparation method and application thereof, and 4D printing degradable inferior vena cava filter

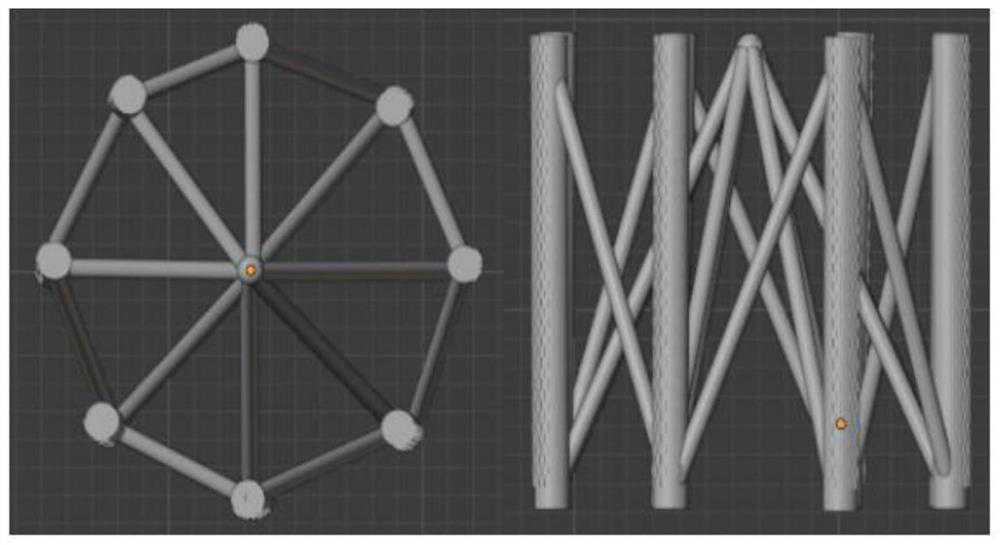

A technology of memory polymer and vena cava, which is applied in the fields of medical formula, drug delivery, medical science, etc., can solve the problems of inferior vena cava perforation, increase the economic burden of patients, and radiation exposure of surgeons, and achieve enhanced mechanical properties and good biological properties. Excellent compatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a preparation method of the degradable shape memory polymer described in the above technical solution, comprising the following steps:

[0040] Mix polyglyceryl sebacate acrylate, hydroxyethyl methacrylate and a photoinitiator, and carry out crosslinking reaction under light conditions to obtain a degradable shape memory polymer.

[0041] The invention mixes polyglyceryl sebacate acrylate, hydroxyethyl methacrylate and photoinitiator. In the present invention, the mass ratio of polyglyceryl sebacate acrylate to hydroxyethyl methacrylate is preferably 1:1˜7:3, more preferably 1.2:1.

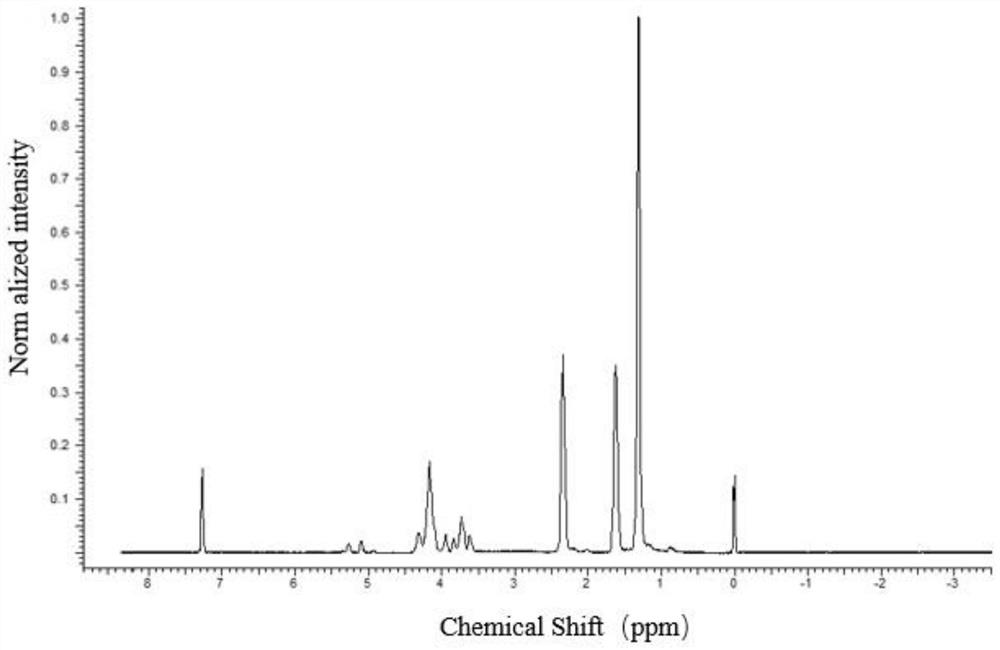

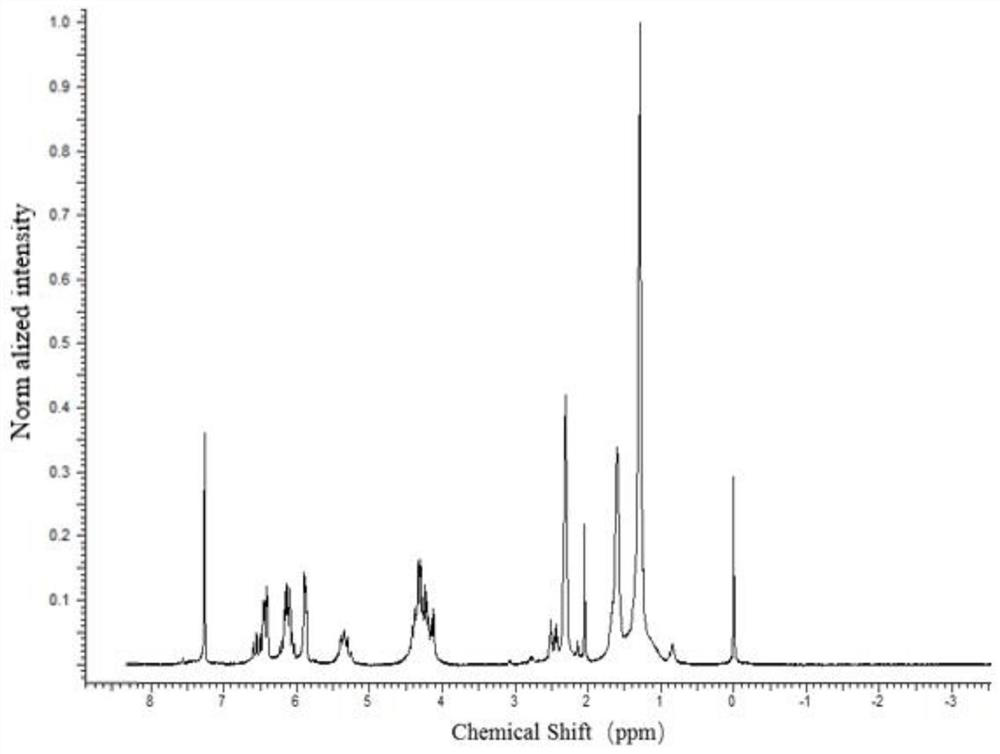

[0042] In the present invention, the polyglyceryl sebacate acrylate has a structure shown in formula 1:

[0043] Formula 1; the number average molecular weight of the polyglyceryl sebacate acrylate is 1900-5100 Da.

[0044] In the present invention, the preparation method of described polyglyceryl sebacate acrylate preferably comprises the following steps: ...

Embodiment 1

[0082] Take by weighing 21g glycerol (glycerol) and 46.1g sebacic acid and add in the there-necked flask, adopt magnetic stirring, N 2 Under protection, carry out the polymerization reaction at 120°C for 24 hours, and use a water separator and a condenser to remove moisture;

[0083] Remove water separator and condenser tube and N 2 Atmosphere, connect the vacuum pump, set the vacuum degree to be-800mbar, and continue to polymerize for 24h to obtain a light yellow viscous PGS polymer (light yellow waxy at room temperature), and the measured number average molecular weight is 3570Da;

[0084] Add 25g PGS polymkeric substance and 250mL methylene dichloride in the there-necked flask, make the mass concentration of gained polyglyceryl sebacate solution be 10%, under N 2 Add 9.9166g of triethylamine under protection, and then magnetically stir for 30min in an ice bath at 4°C to obtain a mixed solution; add 8.869g of acryloyl chloride dropwise to the mixed solution, and continue to...

Embodiment 2

[0088] Take by weighing 21g glycerol (glycerol) and 46.1g sebacic acid and add in the there-necked flask, adopt magnetic stirring, N 2 Under protection, carry out the polymerization reaction at 120°C for 24 hours, and use a water separator and a condenser to remove moisture;

[0089] Remove water separator and condenser tube and N 2 atmosphere, connect the vacuum pump, set the vacuum degree to be-800mbar, and continue to polymerize for 12h to obtain a light yellow viscous PGS polymer (light yellow waxy at room temperature), and the number average molecular weight recorded is 1953Da; and according to the modification of Example 1 The PGSA polymer is prepared by acrylation reaction by a unique method;

[0090] Get 10g PGSA and mix with 5.385g hydroxyethyl methacrylate (mass percentage 65%: 35%), add 307mg photoinitiator DMPA (by mass percentage 2%) and mix uniformly, at wavelength 365nm, intensity 10mW / cm 2 Under the irradiation of ultraviolet light, the crosslinking reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com