Biogas fermentation carbon reduction method for carbon dioxide internal circulation

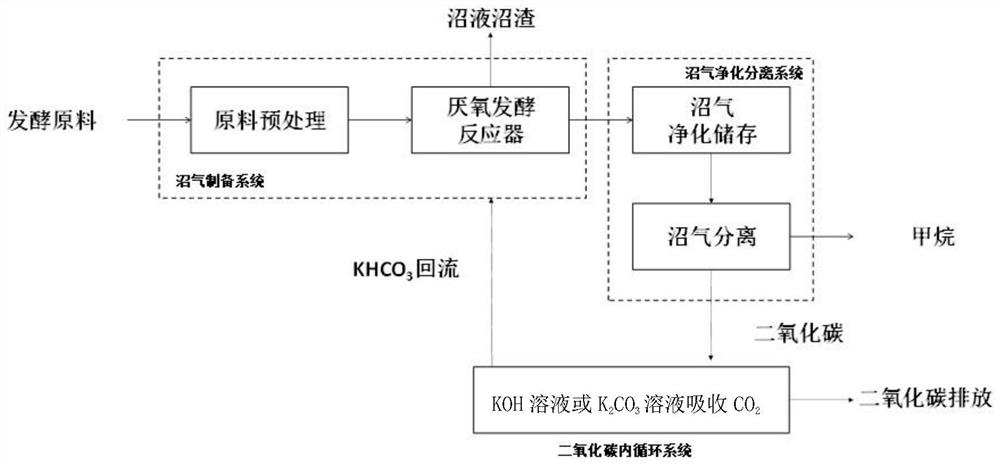

A technology for carbon dioxide and biogas fermentation, applied in chemical instruments and methods, biochemical equipment and methods, fermentation, etc., can solve the problems of less attention to carbon dioxide recovery and reuse, increased operating costs, and increased carbon emissions. Improve purity and application range, promote low-carbon production, reduce carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

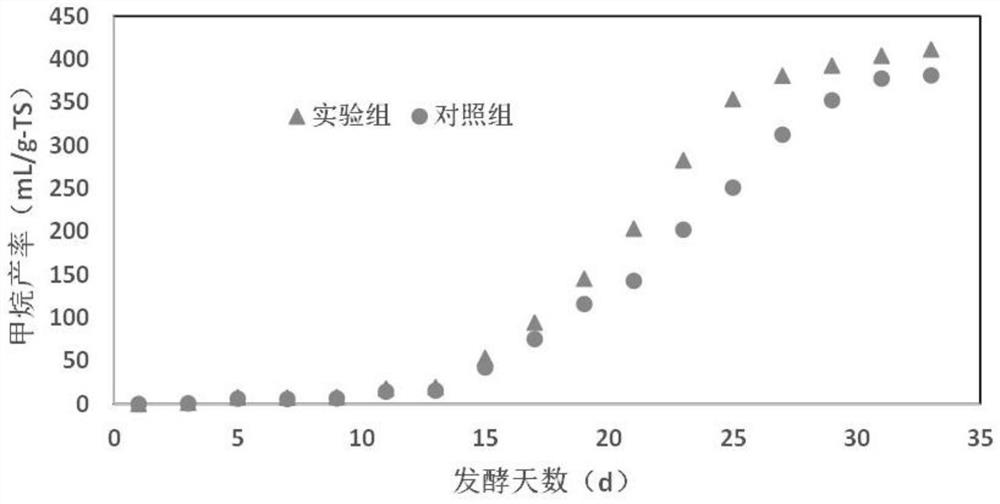

[0038] Select the anaerobic fermentation reactor, the reactor is a 500L anaerobic bottle, the effective volume is 400mL, the food waste is fermented, the fermentation substrate concentration is 35g-VS / L, the inoculation sludge is 16.5g-VS / L, and the fermentation temperature is 40 ℃, the initial pH value is 7.0, N 2 10min to create anaerobic conditions, batch fermentation. Experimental group: Pass the fermentation gas into a 5mL 1mol / L KOH absorption bottle for excessive absorption to obtain CO 2 Absorption liquid, inject the absorption liquid into the anaerobic fermentation bottle, and mix well. Control group: without CO 2 reflow.

[0039] Starting from the injection of the reflux absorption solution, the methane production rate is determined, see figure 2 . Depend on figure 2 It is known that CO is absorbed by lye 2 After internal reflux, the yield of methane increased by 8%. In the rapid gas production stage and after the gas production tends to be stable, the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com