Modified collagen membrane and preparation method thereof, and activated multi-alkynyl cross-linking agent for modifying collagen

A collagen film and polyalkyne-based technology, applied in the field of activated polyalkyne-based cross-linking agents, can solve the problems of long reaction time of epoxy compounds, limited use of cross-linking agents, low cross-linking efficiency, etc., and achieve good biocompatibility , Improve hydrophilic ability, good cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of collagen membrane

[0052] Dissolve the collagen with 1M hydrochloric acid to prepare a 6.5mg / ml collagen solution, then pour the resulting collagen solution into a petri dish, place it on a clean bench and air-dry it to obtain a collagen film. The collagen membrane was rinsed repeatedly with ultrapure water, then soaked in normal saline, and the water was changed at intervals of 30 minutes until the pH of the soaked normal saline remained basically unchanged.

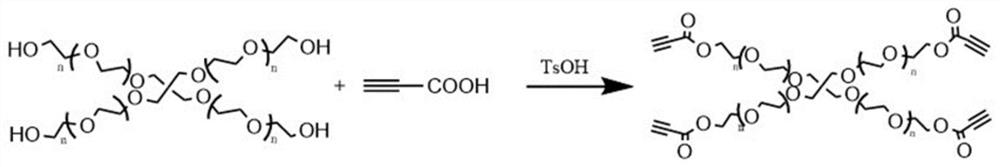

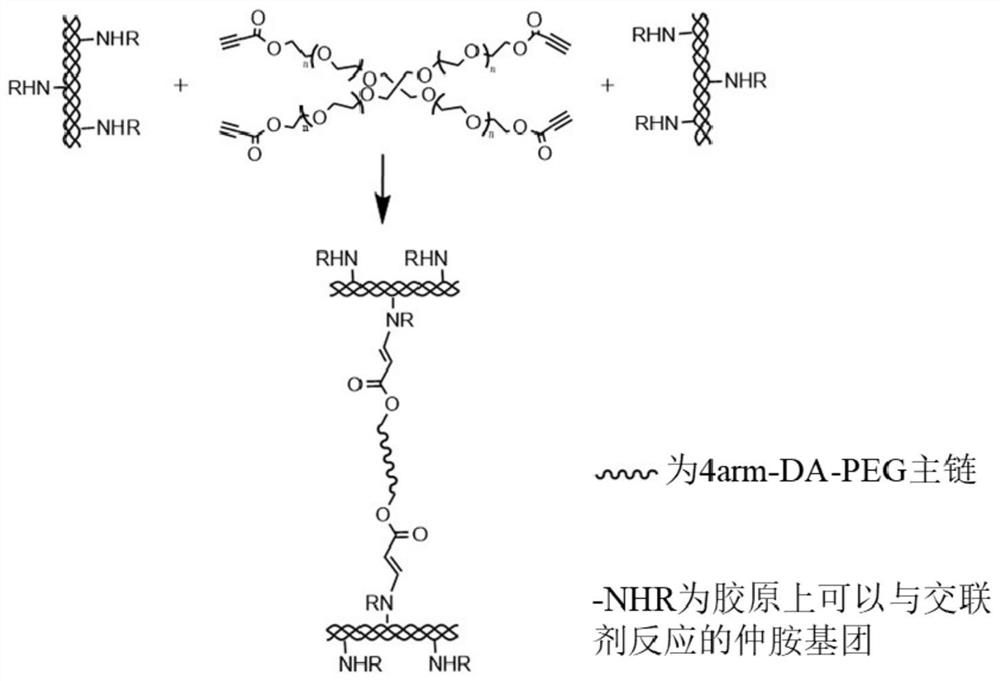

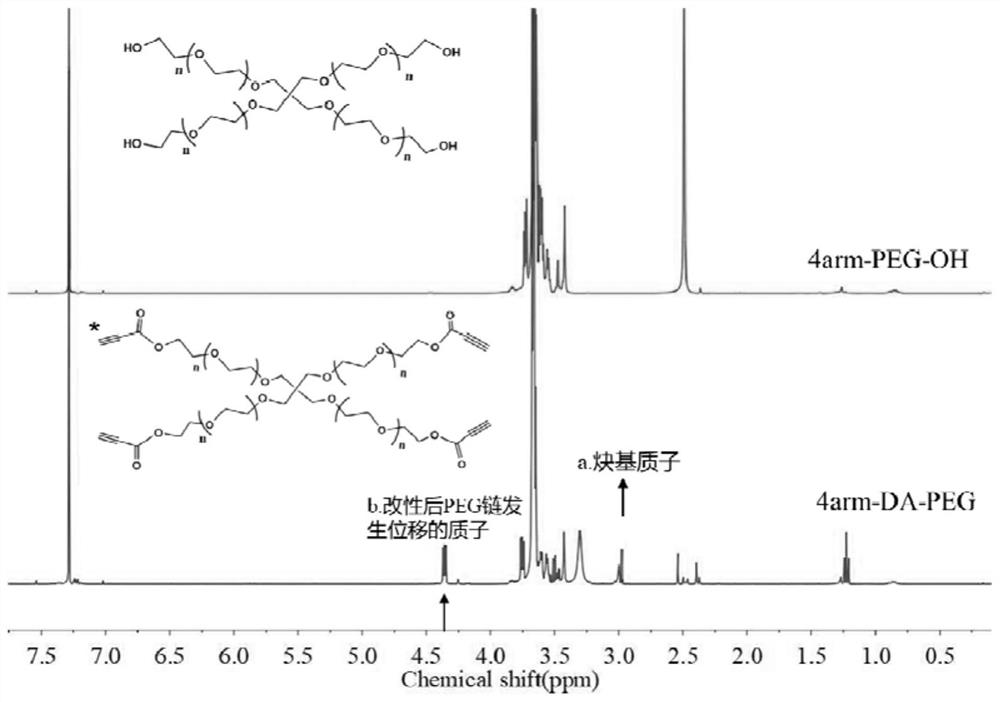

[0053] (2) Synthesis of polyalkyne crosslinker 4arm-DA-PEG

[0054] Weigh 4g of four-arm polyethylene glycol 4arm-PEG-OH (Mn=10000) and 1.12g of propiolic acid into a 150ml round bottom flask, add 60ml of dry toluene solution, and then add 0.1g of p-toluene during magnetic stirring Sulfonic acid monohydrate, heat the mixed solution to 135°C, divide the by-product water during the process of condensation and reflux, take the mixed solution for evaporating and concentrating after 48 hours of reac...

Embodiment 2

[0072] To explore the effect of polyalkyne-based crosslinker 4arm-DA-PEG on the modification of collagen membrane at different temperatures:

[0073] Weigh the 4arm-DA-PEG solid and dissolve it in a conical flask of boric acid-borax buffer (pH=8.4) to form a 4arm-DA-PEG solution with a mass fraction of 20%, adjust the solution to 8.5 with 5M NaOH, add The cut collagen membranes were placed on a temperature-controllable cradle at 4°C, 20°C, and 37°C for 7 hours to obtain a series of 4arm-DA-PEG / Coll crosslinked membranes, which were washed repeatedly with ultrapure water after the reaction. Modification of collagen membranes with polyalkyne-based crosslinkers.

[0074] Cut the sample to be tested into rectangular splines with a width of 7 mm and a length of 20 mm with a knife, fully soak in normal saline for 2 hours, and then wipe off the surface moisture with filter paper. During the experiment, the sample film should always be kept in a wet state. The tensile strength and el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com