Preparation method of bubble film-shaped graphene coated metal phosphide electrode material

A graphene-coated, metal phosphide technology, applied in the direction of phosphide, graphene, nanotechnology for materials and surface science, etc., can solve the problem of low rate performance, low specific capacity, excessive volume change, poor actual stability, etc. problems, to achieve excellent performance, alleviate volume effect, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

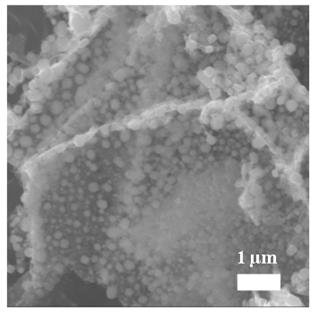

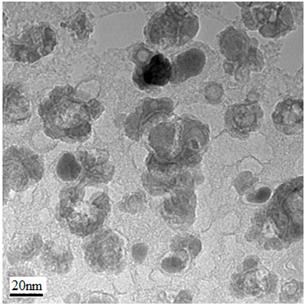

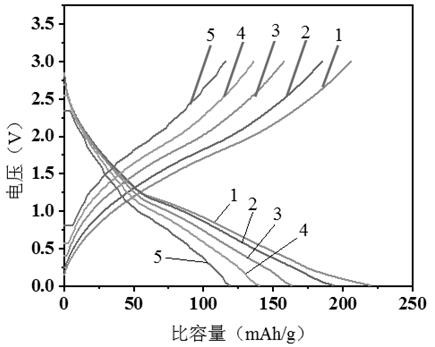

[0027] Dissolve 1mmol ferric nitrate completely in 35mL deionized water to form a ferric nitrate solution; completely dissolve 15g polyvinylpyrrolidone in 60mL deionized water to form a polyvinylpyrrolidone solution; then slowly pour the polyvinylpyrrolidone solution into the ferric nitrate solution, Stir magnetically at 25°C for 4 hours and mix thoroughly to obtain a precursor solution; transfer the precursor solution to a rotary evaporator and keep it warm at 80°C for 16 hours. After the water is completely evaporated, the complex powder is obtained; The material powder is placed in a tube furnace. After vacuuming, argon gas with a flow rate of 50 sccm is introduced, and the temperature is raised to 600 °C at a heating rate of 3 °C / min. Coated metal particle material; mix the bubble film-like graphene-coated metal particle material and NaH at a mass ratio of 1:2 2 PO 2 ·H 2 O, placed in a tube furnace, after evacuating, feed a hydrogen-argon mixture composed of hydrogen an...

Embodiment 2

[0034] 1mmol cobalt chloride is completely dissolved in 10mL deionized water to form a cobalt chloride solution; 15g polydopamine is completely dissolved in 100mL deionized water to form a polydopamine solution; then the polydopamine solution is slowly poured into the cobalt chloride solution, Stir magnetically at 10°C for 5 hours and mix thoroughly to obtain a precursor solution; transfer the precursor solution to a rotary evaporator and keep it warm at 60°C for 24 hours. After the water is completely evaporated, the complex powder is obtained; The material powder is placed in a tube furnace. After vacuuming, nitrogen gas with a flow rate of 10sccm is introduced, and the temperature is raised to 300°C at a heating rate of 1°C / min, kept for 4h, and naturally cooled to room temperature to obtain a bubble film-like graphene coating. Metal particle material; by mass ratio 1: 0.1, mix the bubble film-like graphene-coated metal particle material and Na 2 HPO 4 12H 2 O, placed in ...

Embodiment 3

[0036] Completely dissolve 1mmol nickel acetate in 100mL deionized water to form a nickel acetate solution; completely dissolve 15g polyvinyl alcohol in 10mL deionized water to form a polyvinyl alcohol solution; then slowly pour the polyvinyl alcohol solution into the nickel acetate solution, Stir magnetically at 40°C for 1 hour and mix thoroughly to obtain a precursor solution; transfer the precursor solution to a rotary evaporator and keep it warm at 120°C for 10 hours. After the water is completely evaporated, the complex powder is obtained; The material powder is placed in a tube furnace, and after vacuuming, argon gas with a flow rate of 100 sccm is introduced, and the temperature is raised to 800°C at a heating rate of 10°C / min, kept for 1h, and naturally cooled to room temperature to obtain a bubble film-shaped graphene package. Metal-coated particle material; mix the bubble-film-like graphene-coated metal particle material and NaH at a mass ratio of 1:5 2 PO 4 2H 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com