Fusion enzyme for directional synthesis of dextran as well as construction method and application thereof

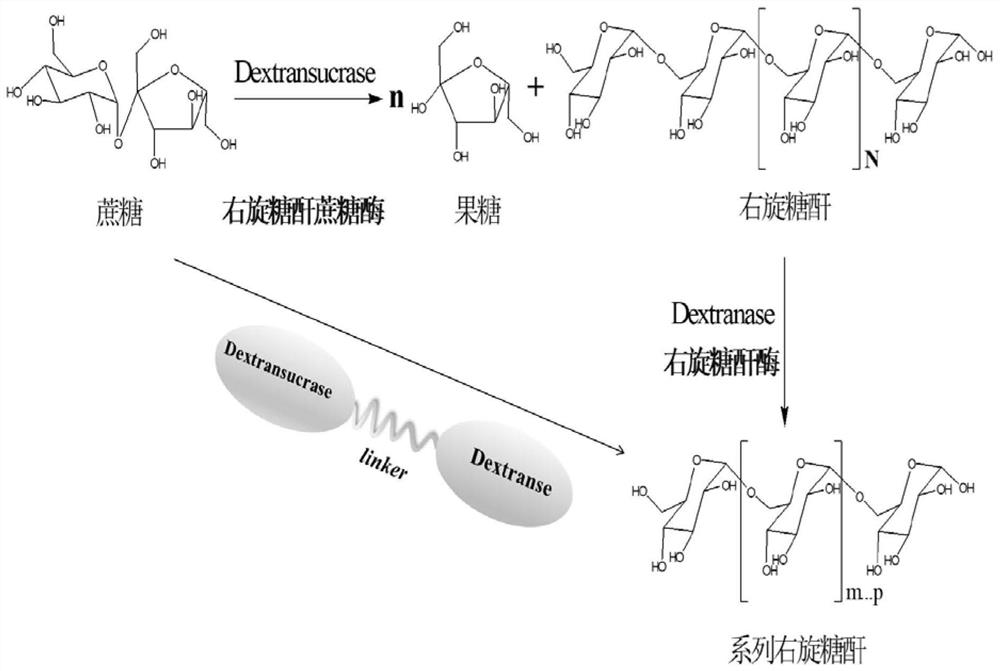

A dextran and construction method technology, applied in the field of directional synthesis of low-molecular-weight dextran fusion enzyme construction, can solve the problems of uniformity, restriction of catalytic efficiency, and difficulty in controlling the distance between enzyme molecules, and achieve high conversion rate and simple separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

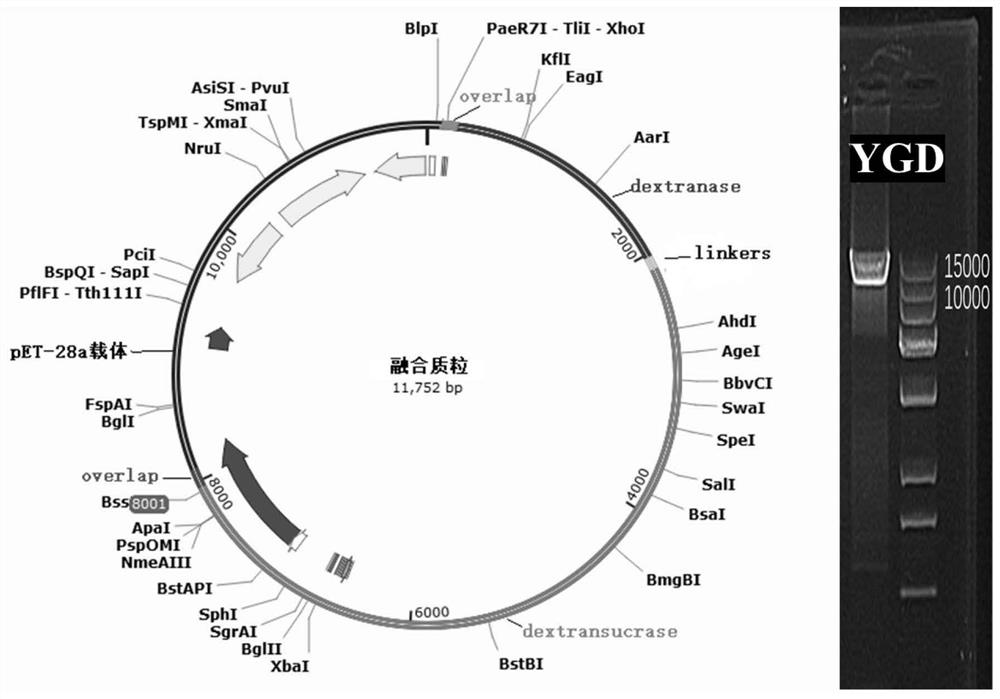

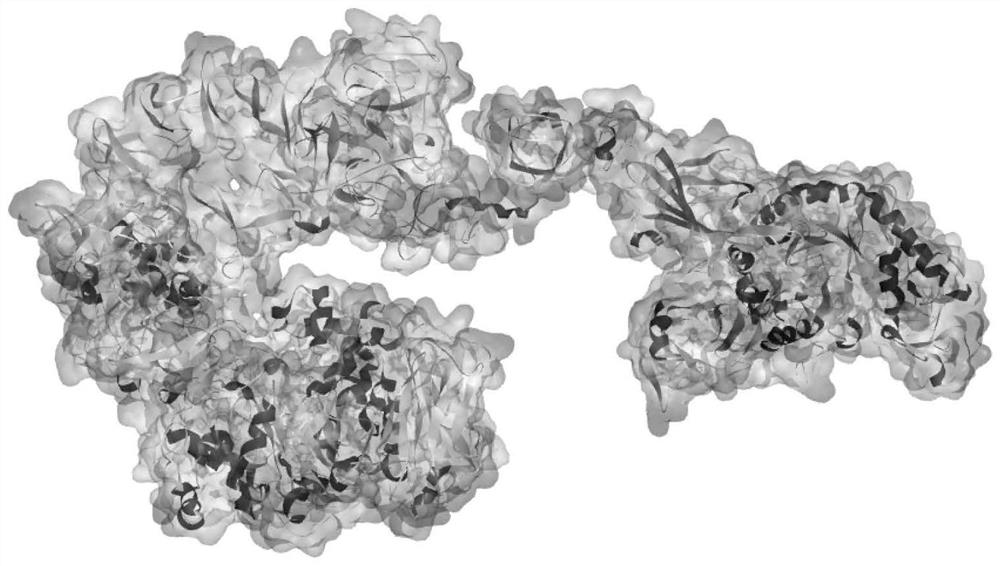

[0064] A method for constructing a fusion enzyme Escherichia coli capable of directional synthesis of dextran, using P473S / P856S double mutant heat-stable dextran sucrase gene and streptococcus-derived dextranase gene as templates, using (EAAAK) 1 Homologous recombination of two enzyme genes in order to connect peptides and transformation into BL21(DE3) Escherichia coli to obtain a fusion enzyme capable of directional synthesis of dextran Escherichia coli BL21(DE3) / dex-YG-G-a1dex genetic engineering bacteria. The other two fusion enzyme genetic engineering bacteria and construction methods are consistent with BL21(DE3) / dex-YG-G-a1dex genetic engineering bacteria. The BL21(DE3) / dex-YG-G-a1dex genetically engineered bacterium is preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee (No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing), and the classification is named Directed Synthesis Low-molecular-weight dextran ...

Embodiment 2

[0085] Expression of Fusion Enzyme Escherichia coli BL21(DE3) / dex-YG-G-a1dex Genetic Engineering Bacteria Capable of Directly Synthesizing Dextran

[0086] The genetically engineered bacterium BL21(DE3) / dex-YG-G-a1dex that embodiment 1 obtains is inoculated in the LB culture medium that contains 40~60 μ g / ml kanamycin by the inoculum size of 0.5%, rotating speed 250r / min, Cultivate at 37°C for 16 hours; draw 2mL from the above culture solution and add it to 200mL of medium A, culture on a shaker at 37°C, when the enriched culture solution is diluted 10 times with distilled water, the OD 600 Add 500μL IPTG to induce enzyme production at 0.20~0.24 o’clock. After inducing fermentation at 25℃ for 3.5~4 hours, carry out crushing and centrifugation, and perform high-performance liquid chromatography analysis on the samples taken. The protein molecular weight of the expressed fusion enzyme is about 265KDa, consistent with the predicted value. Wherein, each liter of the A medium cont...

Embodiment 3

[0088] The fermentation enzyme production of the fusion enzyme E. coli engineering bacteria BL21(DE3) / dex-YG-G-a1dex genetically engineered bacteria capable of directional synthesis of dextran specifically includes the following steps:

[0089] Inoculate the genetically engineered bacteria BL21(DE3) / dex-YG-G-a1dex into the LB medium containing 40-60 μg / ml kanamycin at an inoculum size of 0.5% by volume fraction, at a speed of 250 r / min, at 37° C. Cultivate under low temperature for 16 hours; draw 2mL from the above culture solution and add it to 200mL A medium, place it on a shaker at 37°C for culture, when the enriched culture solution is diluted 10 times with distilled water, the OD 600 At 0.20 to 0.24, add 500 μL IPTG to induce enzyme production, keep at 25°C to induce fermentation for 3.5 to 4 hours, and centrifuge the bacterial suspension after induced fermentation at 4°C at 8000r / min for 15min, and a centrifuge tube corresponds to Add a bottle of bacterial suspension, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protein molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com