In-situ preparation method of flexible piezoelectric photocatalysis nanofibers

A nanofiber, in-situ preparation technology, applied in chemical instruments and methods, nanotechnology, fiber processing, etc., can solve problems such as easy degradation, achieve high effective interface contact, reduce grain size, and reduce brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

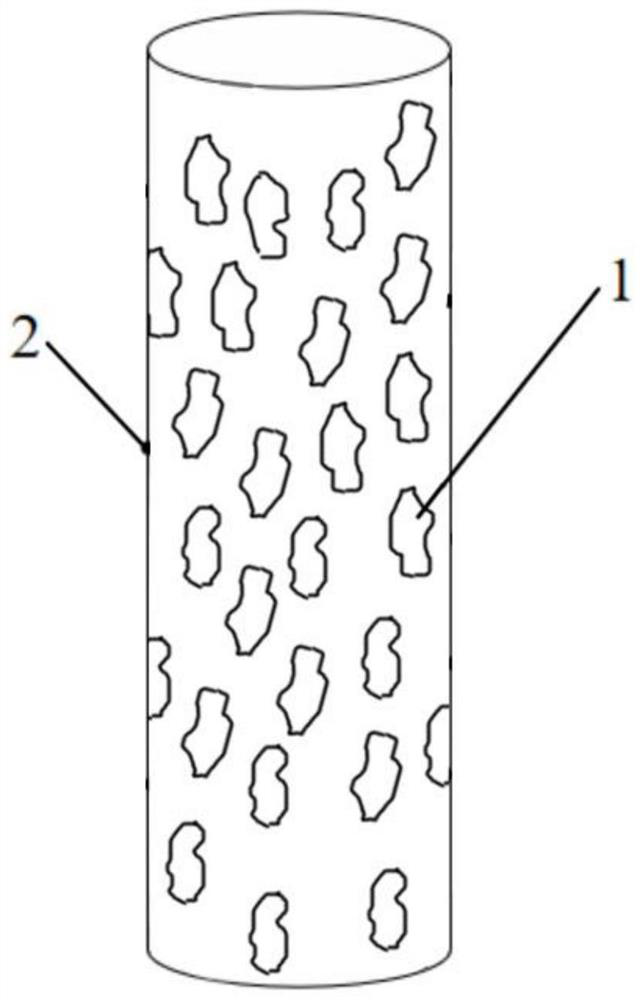

Image

Examples

Embodiment 1

[0047] Preparation of BaTiO 3 -TiO 2 Composite Flexible Fiber Membrane

[0048] Put 1g of yttrium nitrate hexahydrate, 3.5g of isopropyl titanate, 1g of PVP, 6g of DMF and 2g of glacial acetic acid into the propulsion pump, adjust the spinning voltage to 12kv, and the receiving distance to 18cm. The silk temperature is 30°C, the humidity is 10%, the propulsion pump speed is 0.3mL / h, electrospinning is carried out, and then calcined at 550°C for 2h to obtain flexible TiO 2 Nanofibers;

[0049] Weigh 3g of butyl titanate according to Ba:Ti=1, add 10ml of glacial acetic acid and 10ml of absolute ethanol at room temperature, then add 1.456g of barium acetate aqueous solution dropwise under stirring, and stir for 30min to form a uniform and transparent mixed sol.

[0050] Flexible TiO 2 The fiber membrane was fixed on a spin coater, and a mass ratio of 0.1mol / L (CTAC:Ba(NO 3 ) 2 =7:3) The mixed solution is dropped onto the center of the film, and the spin coater rotates at a ...

Embodiment 2

[0053] Preparation of BaTiO 3 -ZnO Composite Flexible Fiber Membrane

[0054] Put 0.8g of yttrium nitrate hexahydrate, 3.5g of zinc nitrate, 1.5g of PVP, 6g of DMF and 2g of glacial acetic acid into the propulsion pump, adjust the spinning voltage to 12kv, and the receiving distance to 18cm. The temperature is 30°C, the humidity is 10%, the propulsion pump speed is 0.3mL / h, electrospinning is carried out, and then calcined at 550°C for 2 hours to obtain flexible ZnO nanofibers;

[0055] Weigh 3g of butyl titanate according to Ba:Ti=1, add 10ml of glacial acetic acid and 10ml of absolute ethanol at room temperature, then add 1.456g of barium acetate aqueous solution dropwise under stirring, and stir for 30min to form a uniform and transparent mixed sol.

[0056] The flexible ZnO fiber membrane was fixed on a spin coater, and a mass ratio of 0.1mol / L (CTAB:Ba(NO 3 ) 2 =3:2) The mixed solution is dropped onto the center of the film, and the spin coater rotates at a speed of 20...

Embodiment 3

[0059] Preparation of ZnO-TiO 2 Composite Flexible Fiber Membrane

[0060] Put 1g of yttrium nitrate hexahydrate, 3.5g of isopropyl titanate, 1g of PVP, 6g of DMF and 2g of glacial acetic acid into the propulsion pump, adjust the spinning voltage to 12kv, and the receiving distance to 18cm. The silk temperature is 30°C, the humidity is 10%, the propulsion pump speed is 0.3mL / h, electrospinning is carried out, and then calcined at 550°C for 2h to obtain flexible TiO 2 Nanofibers;

[0061] Select zinc acetate dihydrate as a precursor, ethylene glycol methyl ether as an organic solvent, and ethanolamine as a stabilizer, dissolve 3.78g of zinc acetate dihydrate in 4.3g of ethylene glycol methyl ether, then add equimolar ethanolamine, Stir well at 75°C for 2 hours to form a light yellow transparent solution with a zinc ion concentration of 0.5 mol / L.

[0062] Flexible TiO 2 The fiber membrane was fixed on a spin coater, and a mass ratio of 0.1mol / L (CTAC:Zn(NO 3 ) 2 =5:1) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com