Active oxygen-eliminating antibacterial and anti-inflammatory hydrogel skin dressing and preparation method thereof

An antibacterial, anti-inflammatory, and hydrogel technology, applied in medical science, bandages, etc., can solve problems such as difficult storage, poor mechanical properties of hydrogels, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

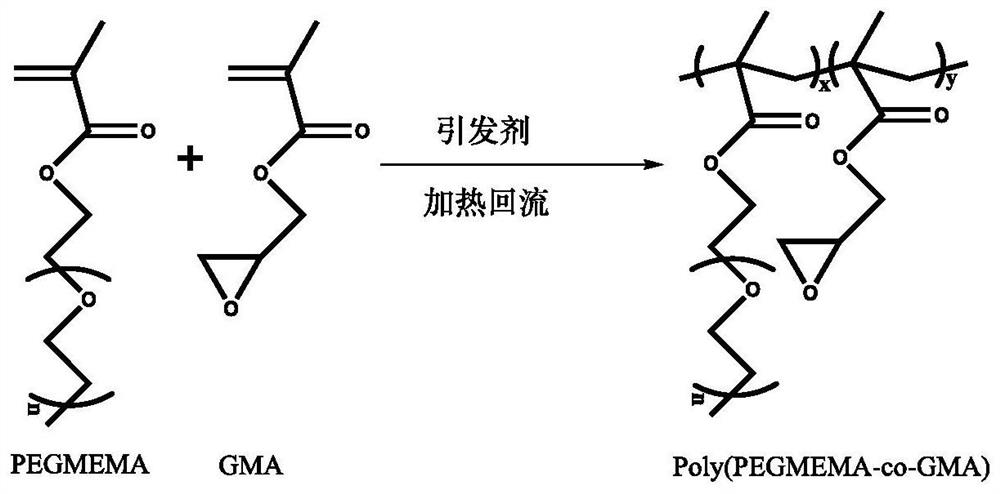

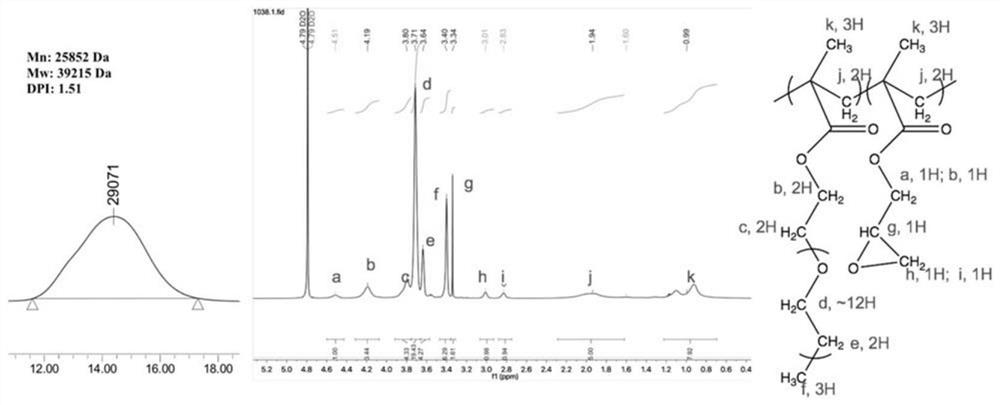

[0028]The first step: under nitrogen protection, 25.5g polyethylene glycol methyl ether methacrylate monomer (Mn=300), 6.4g glycidyl methacrylate monomer and 3.3g azobisisobutyronitrile were dissolved in 300ml In methanol solvent, magnetically stirred, heated to reflux at 70 degrees Celsius for 10 hours; after the reaction, the reaction solution was precipitated in glacial ether, the product was collected by centrifugation, and the crude product was obtained after drying; the crude product was dissolved in methanol, and then settled in glacial ether to remove Miscellaneous, collect product after repeating three times, vacuum drying obtains poly(polyethylene glycol methyl ether methacrylate-co-glycidyl methacrylate);

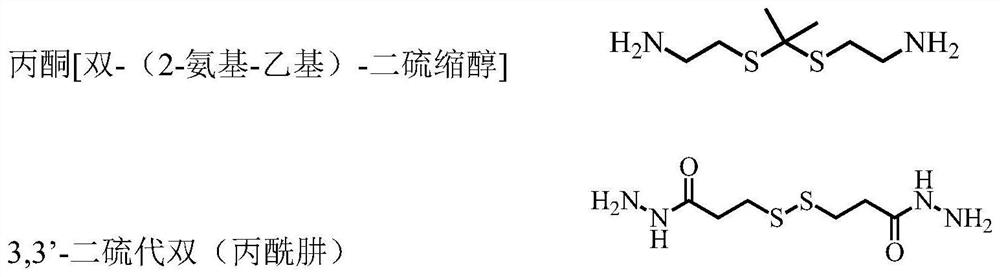

[0029] The second step: 0.8g of poly(polyethylene glycol methyl ether methacrylate-co-glycidyl methacrylate) prepared in the first step, 82.8mg of acetone [bis-(2-amino-ethyl)- Dithiol] and 51.4mg 3,3'-dithiobis(propionyl hydrazide) were dissolved in 4ml 0.5wt% p...

Embodiment 2

[0035] The first step: under nitrogen protection, 14.17g polyethylene glycol methyl ether methacrylate monomer (Mn=300), 3.56g glycidyl methacrylate monomer and 1.60g azobisisobutyronitrile were dissolved in 100ml In methanol solvent, magnetically stirred, heated to reflux at 70°C for 10 h; precipitated the reaction solution in glacial ether, centrifuged to collect the product, and dried to obtain a crude product; dissolved the crude product in methanol, then settled in glacial ether to remove impurities, and repeated After three times, the product was collected and vacuum-dried to obtain poly(polyethylene glycol methyl ether methacrylate-co-glycidyl methacrylate);

[0036] The second step: 0.2g of poly(polyethylene glycol methyl ether methacrylate-co-glycidyl methacrylate) prepared in the first step, 12.9mg of acetone [bis-(2-amino-ethyl)- Dithiol] and 22.5mg 3,3'-dithiobis(propionyl hydrazide) were dissolved in 1ml 1wt% polyvinyl alcohol solution to obtain a hydrogel prepoly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com