Basic catalyst and preparation method and application thereof

A technology of catalysts and co-catalysts, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, physical/chemical process catalysts, etc., can solve the problems of occupying land resources, polluting the environment, reducing the life of catalysts, etc., and achieve a higher ratio Surface area, overcoming secondary pollution, and improving the effect of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

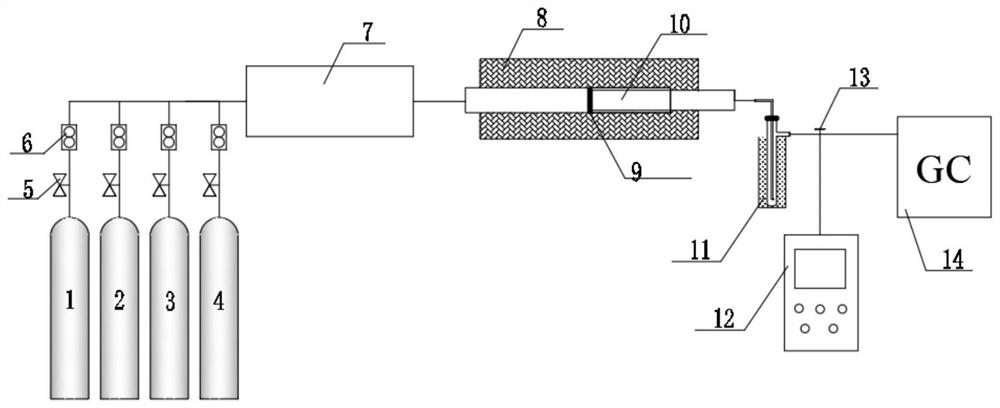

Method used

Image

Examples

Embodiment 1

[0026] a, 20.18g MgCl 2 ·6H 2 O and 4.04g C 12 h 12 o 11 respectively dissolved in 150mL and 25mLH 2 In O, the sucrose solution was slowly added dropwise to the MgCl 2 ·6H 2 O solution and mix well to obtain the mixed solution 1.

[0027] b. Add 0.40gCe(NO 3 ) 3 ·6H 2 O, 0.10gEu(NO 3 ) 3 ·6H 2 O, 0.01g KNO 3 , 0.06g Ca(NO 3 ) 4 4H 2 O was dissolved in 25ml of water and slowly added to the mixed solution 1, placed in a magnetic stirrer at 80°C and stirred at a constant speed for 4 hours to obtain the mixed solution 2;

[0028] c. Add 25ml of ammonia water to the mixed solution 2, place it in a magnetic stirrer at 80°C and stir for 2h at a constant speed, then place it in a blast drying oven at 100°C for heat preservation and drying, then place it in a muffle furnace for 4 hours of roasting at 600°C in an air atmosphere Prepared catalyst, wherein based on the carrier mass, the mass fraction of the active component is 5%, the mass fraction of the promoter is 0.5%...

Embodiment 2

[0031] a, 20.18g MgCl 2 ·6H 2 O and 5.05g C 12 h 12 o 11 respectively dissolved in 150mL and 25mLH 2 In O, the sucrose solution was slowly added dropwise to the MgCl 2 ·6H 2 O solution and mix well to obtain the mixed solution 1.

[0032] b. Add 0.66g Ce(NO 3 ) 3 ·6H 2 O, 0.33gEu(NO 3 ) 3 ·6H 2 O, 0.02g KNO 3 , 0.13g Ca(NO 3 ) 4 4H 2 O was dissolved in 25ml of water and slowly added to the mixed solution 1, placed in a magnetic stirrer at 75°C and stirred at a constant speed for 6 hours to obtain the mixed solution 2;

[0033] c. Add 25ml of ammonia water to the mixed solution 2, place it in a magnetic stirrer at 80°C for 4h at a constant speed, then place it in a blast drying oven at 120°C for heat preservation and drying, and then place it in a muffle furnace for 4h roasting at 550°C in an air atmosphere. Obtain catalyst, wherein take carrier mass as benchmark, the massfraction of active component is 10%, the massfraction of cocatalyst is 1%, the component m...

Embodiment 3

[0036] a, 20.18g MgCl 2 ·6H 2 O and 4.04g C 12 h 12 o 11 respectively dissolved in 150mL and 25mLH 2 In O, the sucrose solution was slowly added dropwise to the MgCl 2 ·6H 2 O solution and mix well to obtain the mixed solution 1.

[0037] b. Add 0.33g CeCl 3 ·6H 2 O, 0.08g EuCl 3 ·6H 2 O, 0.01g KCl, 0.03g CaCl 2 Dissolved in 25ml of water, slowly added to mixed solution 1, placed in a magnetic stirrer at 80°C and stirred at a constant speed for 4 hours to obtain mixed solution 2;

[0038] c. Add 25ml of ammonia water to the mixed solution 2, place it in a magnetic stirrer at 80°C and stir for 2h at a constant speed, then place it in a blast drying oven at 100°C for heat preservation and drying, then place it in a muffle furnace for 4 hours of roasting at 600°C in an air atmosphere Prepared catalyst, wherein based on the carrier mass, the mass fraction of the active component is 5%, the mass fraction of the promoter is 0.5%, and the component mass ratio of cerium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com