Catalyst for decomposing nitrous oxide, preparation method of catalyst and nitrous oxide decomposition method

A nitrous oxide and catalyst technology, applied in the direction of nitrous oxide capture, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of reducing operating costs and short catalyst life cycles Easy deactivation, reducing initial equipment investment, etc., to achieve the effect of reducing operating costs, increasing long-term stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

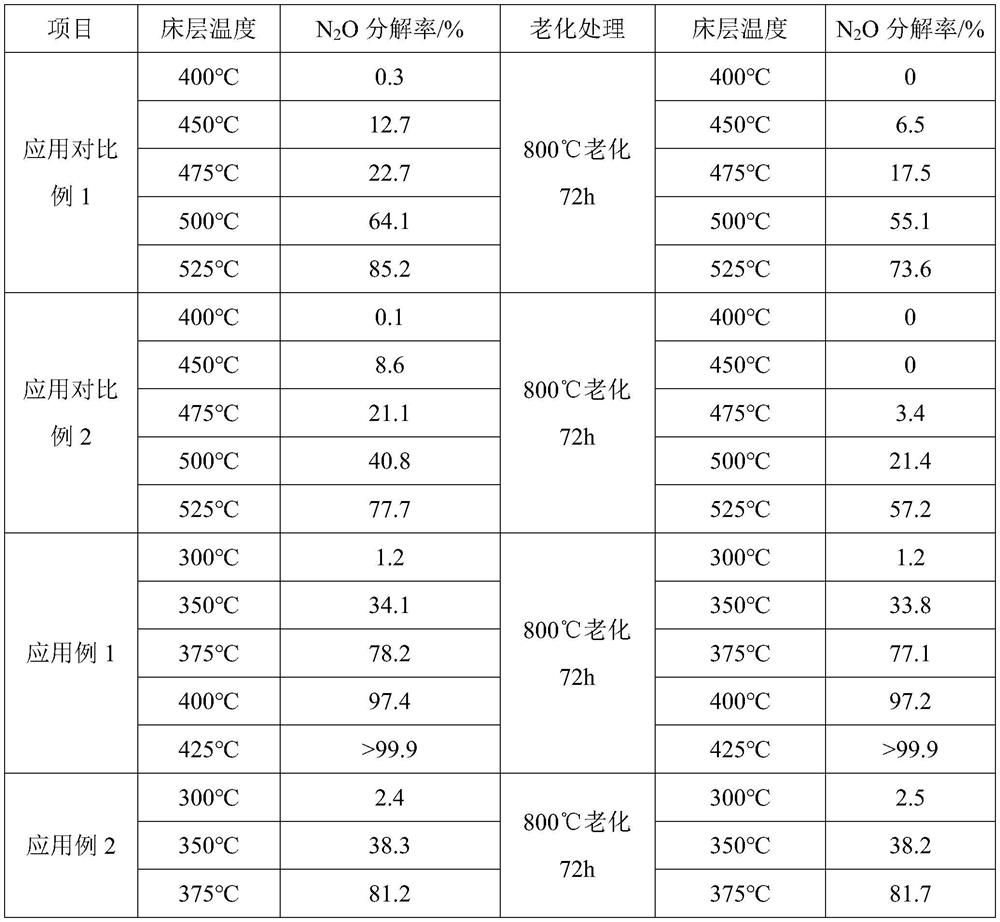

[0067] This embodiment provides a preparation method for a catalyst for decomposing nitrous oxide. The preparation method comprises: taking 0.4mol of cobalt acetate, 0.05mol of potassium hydroxide, 0.3mol of calcium hydroxide, 0.35mol of zinc oxide, and 5g of scallop powder Mix with 152g yttrium acetate-modified pseudo-boehmite (1mol alumina, 0.01mol yttrium acetate-modified) and knead with 70ml (containing 10ml formic acid and 5ml citric acid) aqueous solution, extrude 2mm strips, 120°C Drying for 12 hours, calcining at 800° C. for 6 hours, the molar ratio of catalyst components cobalt:potassium:calcium:zinc:yttrium:aluminum=0.4:0.05:0.3:0.35:0.01:2 was obtained. Denoted as catalyst I, the figure of the catalyst I is as follows figure 1 shown.

Embodiment 2

[0069] This embodiment provides a preparation method of a catalyst for decomposing nitrous oxide. The preparation method comprises: taking 0.3 mol of ferric hydroxide, 0.02 mol of strontium hydroxide, 0.3 mol of magnesium carbonate, 0.5 mol of basic zinc carbonate, 10 g of formazan Base cellulose and 153g of yttrium acetate-modified pseudoboehmite (1mol alumina, 0.02mol of yttrium acetate modification) were mixed and kneaded with 70ml (containing 5ml of formic acid and 15ml of citric acid) aqueous solution, extruding a 2mm strip , dried at 120°C for 12h, and calcined at 800°C for 6h to obtain the catalyst component molar ratio iron:strontium:magnesium:zinc:yttrium:aluminum=0.3:0.02:0.3:0.5:0.02:2, denoted as catalyst II.

Embodiment 3

[0071] This embodiment provides a preparation method of a catalyst for decomposing nitrous oxide, the preparation method comprising: taking 0.2mol nickel acetate, 0.03mol sodium hydroxide, 0.4mol magnesium carbonate, 0.5mol basic zinc carbonate, 10g methyl Cellulose and 153g of neodymium acetate-modified pseudo-boehmite (1mol alumina, 0.02mol of neodymium acetate modification) were mixed and kneaded with 80ml (containing 10ml formic acid and 10ml citric acid) aqueous solution, extruding 2mm strips, Drying at 120°C for 12 hours, and calcining at 800°C for 12 hours, the molar ratio of catalyst components nickel:sodium:magnesium:zinc:neodymium:aluminum=0.2:0.03:0.4:0.5:0.02:2 was obtained, which was designated as catalyst III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com