Preparation method and application of Ag/ZnO/CdS composite photocatalyst

A technology of catalyst and composite light, which is used in composite photocatalysts and in photocatalytic degradation of organic matter and antibacterial applications. In the field of preparation of nanocomposite photocatalyst Ag/ZnO/CdS, it can solve unfavorable photocatalytic activity and sterilization performance, The problems of CdS nanocrystal shedding and low valence band potential of CdS achieve excellent photocatalytic antibacterial performance, enhanced photocatalytic and sterilization performance, and excellent photocatalytic degradation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

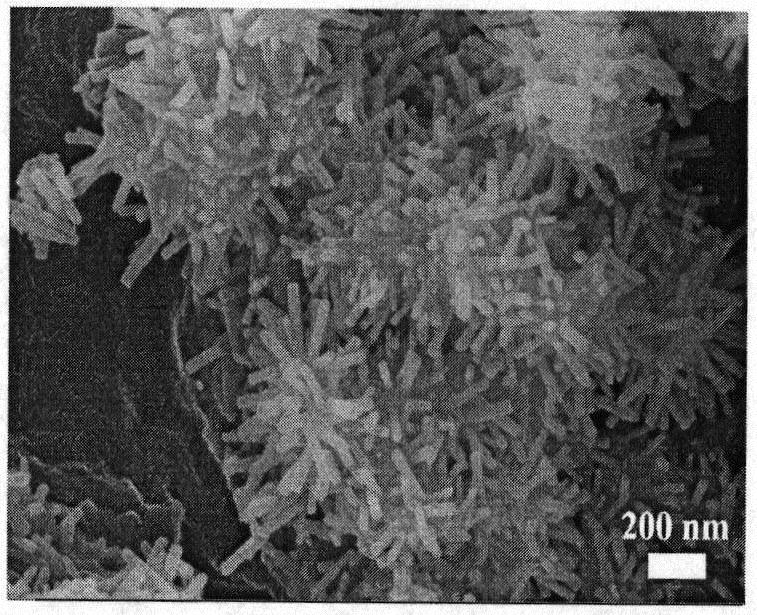

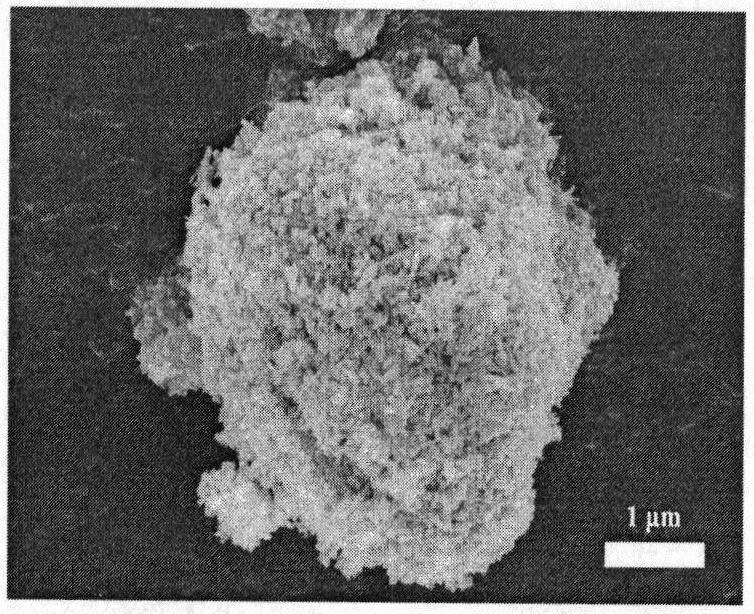

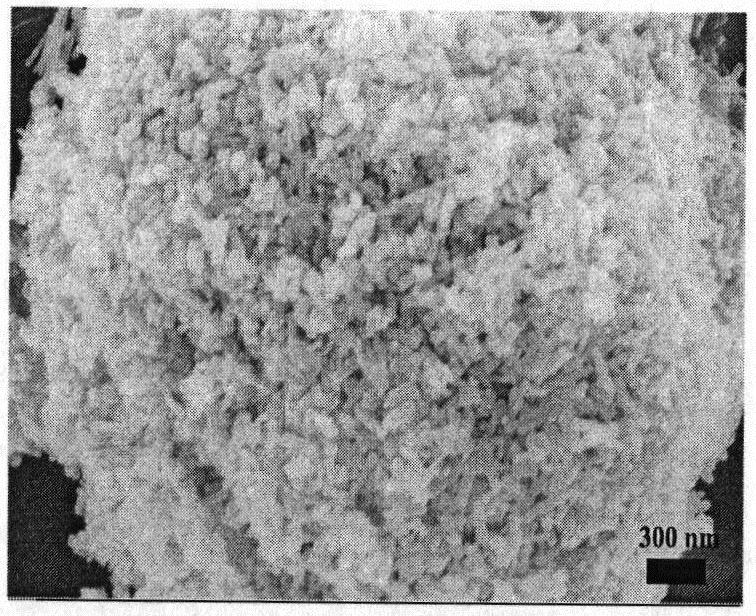

Image

Examples

Embodiment 1

[0056] The preparation method of composite photocatalyst Ag / ZnO / CdS comprises the following steps:

[0057] (1) Preparation of CdS crystals: Dissolve 0.005 mol of cadmium nitrate and 0.015 mol of thiourea in 50 mL of deionized water, after stirring for 1 hour, add 0.3 g of polyvinylpyrrolidone powder and continue stirring for 30 minutes until the solution is clear, then the above The solution was transferred to a reaction kettle, and reacted at a constant temperature of 200°C for 5 hours;

[0058] (2) Preparation of ZnO sol: Dissolve 0.6mmol sodium hydroxide solution in 20mL of absolute ethanol and stir evenly to obtain solution A, then dissolve 0.5mmol zinc acetate in 50mL of absolute ethanol and stir to obtain solution B, and then dissolve solution A Mix with solution B and stir at 60°C for 2 hours to obtain ZnO sol, and let it stand for 12 hours for later use;

[0059] (3) Preparation of ZnO solution: Dissolve 0.01 mol of zinc nitrate and 0.01 mol of hexamethylenetetramine...

Embodiment 2

[0063] The specific steps are consistent with Example 1, except that the cadmium salt selected in the step (1) is cadmium chloride, and all the other conditions are unchanged.

Embodiment 3

[0065] The specific steps are consistent with Example 1, except that the cadmium salt selected in the step (1) is cadmium sulfate, and all the other conditions are unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com