Breathable membrane for culturing high-yield varicella virus and culture method of high-yield varicella virus

A technology of varicella virus and culture method, which is applied in the direction of virus, virus/bacteriophage, double-stranded DNA virus, etc. It can solve the problems of not having oxygen selectivity, affecting the proliferation of varicella virus, affecting oxygen supply, etc., and achieving high-yield culture , enhance cell adhesion, enhance the effect of proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

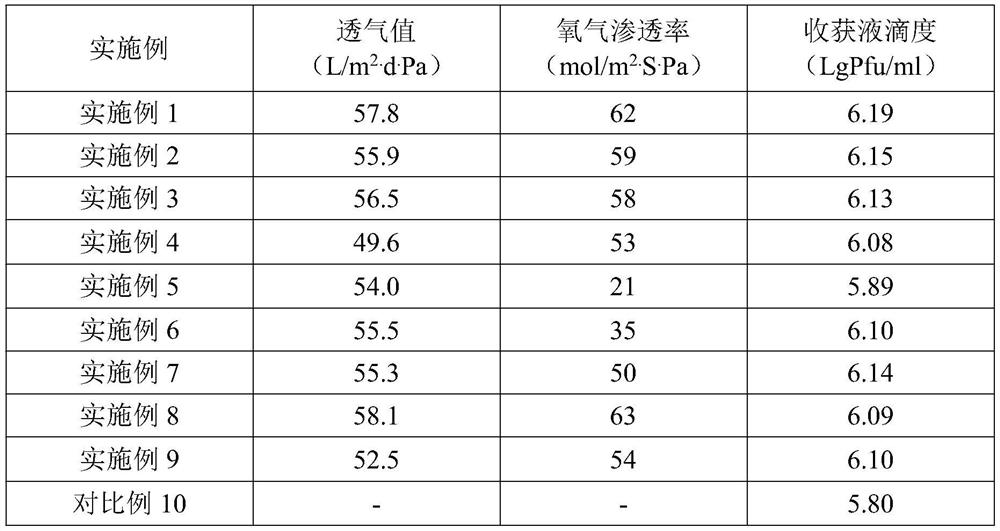

Examples

Embodiment 1

[0036] S1: Dissolve polypropylene and polycaprolactone in DMF-dichloromethane mixed solvent as a spinning solution, set the conditions: temperature is 25°C, relative humidity is 50%, feeding speed is 0.5mL / h, receiving distance 15cm, voltage 13Kv, electrospinning to obtain a fiber membrane; place it in a 0.4mol / L arginine aqueous solution, set the temperature at 40°C, shake for 2 hours, wash with water, and obtain a polycaprolactone composite membrane ,spare;

[0037] S2: (1) Set the temperature at 0°C, add the sodium nitrite solution to the pyridine solution and mix, add the multi-walled carbon nanotube dispersion, and stir for 2.5 hours; set the temperature at 26°C, stir for 9 hours, and wash until Neutral, dry; under inert gas, ultrasonically disperse it in the solvent, add cobalt phthalocyanine, set the temperature at 72°C and reflux for 2.3 hours, wash and filter; disperse it and polypropylene pyrrolidone in DMF-water, ultrasonic for 7 hours, Washing and drying to obtain...

Embodiment 2

[0041] S1: Dissolve polypropylene and polycaprolactone in DMF-dichloromethane mixed solvent as a spinning solution, set the conditions: temperature is 23°C, relative humidity is 48%, feeding speed is 0.4mL / h, receiving distance 15cm, voltage 12Kv, electrospinning to obtain a fiber membrane; place it in 0.1mol / L arginine aqueous solution, set the temperature at 28-42°C, shake for 1 hour, wash with water to obtain polycaprolactone Composite film, spare;

[0042] S2: (1) Set the temperature at 0°C, add the sodium nitrite solution to the pyridine solution and mix, add the multi-walled carbon nanotube dispersion, and stir for 2 hours; set the temperature at 25°C, stir for 8 hours, and wash until Neutral, dry; under inert gas, ultrasonically disperse it in the solvent, add cobalt phthalocyanine, set the temperature at 70°C to reflux for 2 hours, wash and filter; disperse it and polypropylene pyrrolidone in DMF-water, ultrasonic for 6 hours, Washing and drying to obtain cobalt phtha...

Embodiment 3

[0046] S1: Dissolve polypropylene and polycaprolactone in a mixed solvent of DMF-dichloromethane as a spinning solution, setting conditions: temperature 28°C, relative humidity 52%, feeding speed 0.6mL / h, receiving distance 15cm, voltage 15Kv, electrospinning to obtain a fiber membrane; place it in a 0.5mol / L arginine aqueous solution, set the temperature at 42°C, shake for 2 hours, wash with water, and obtain a polycaprolactone composite membrane ,spare;

[0047] S2: (1) Set the temperature at 3°C, add the sodium nitrite solution to the pyridine solution and mix, add the multi-walled carbon nanotube dispersion, and stir for 3 hours; set the temperature at 28°C, stir for 10 hours, and wash until Neutral, dry; under inert gas, ultrasonically disperse it in the solvent, add cobalt phthalocyanine, set the temperature at 75°C to reflux for 3 hours, wash and filter; disperse it and polypropylene pyrrolidone in DMF-water, ultrasonically for 8 hours, Washing and drying to obtain cob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com