Tissue engineering dental pulp based on digital optical processing printing technology and preparation method

A technology of digital optics and tissue engineering, applied in biochemical equipment and methods, tissue regeneration, tissue culture, etc., can solve the problems of increased fragility and easy staining of dental hard tissues, and achieve the effect of promoting dental pulp regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

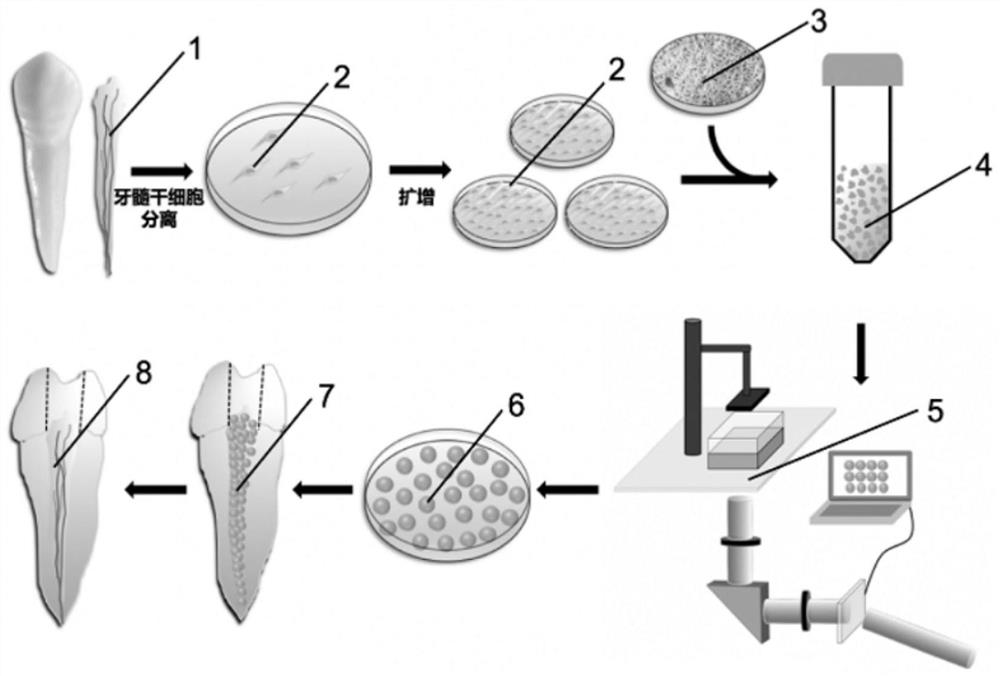

[0033] A method for preparing tissue-engineered dental pulp based on digital optical processing and printing technology, the preparation method comprising the following steps:

[0034] The acquisition and cultivation of dental pulp mesenchymal stem cells;

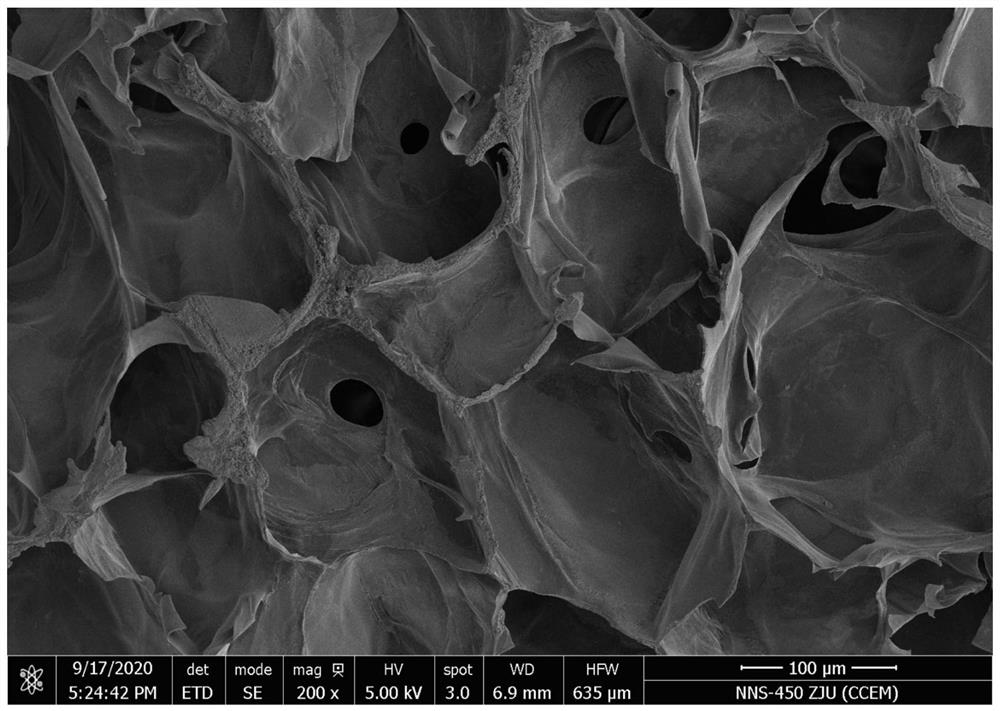

[0035] Preparation of GelMA hydrogel;

[0036] After the dental pulp mesenchymal stem cells obtained in the above steps were digested and centrifuged, they were resuspended with medium, and the resulting cell suspension was mixed with GelMA (1M) hydrogel evenly, and then the bioink was transferred to the sample tank of the 3D printer (already Preheat to 37°C), and print layer by layer through digital light processing 3D printing technology.

[0037] According to the above preparation method, wherein the cell suspension is a cell suspension containing dental pulp mesenchymal stem cells.

[0038] The above-mentioned application of tissue engineering dental pulp based on digital optical processing and printing technology.

...

Embodiment 1

[0057] Example 1: Preparation of tissue engineered dental pulp based on digital optical processing and printing technology

[0058] (1) Cultivation and expansion of dental pulp cells: the patient’s teeth were quickly stored in α-MEM medium (Gibco, USA) containing penicillin (100 Units / mL) and streptomycin (100 Units / mL), and transferred into ultra-clean Taiwan. Disinfect the water and air pipes of the turbine with povidone iodine. After cross-sectioning the tooth, use a probe to take out the pulp completely, wash it three times with PBS containing penicillin (100Units / mL) and streptomycin (100Units / mL), and transfer it to the EP tube. Cut the pulp tissue into pieces with tissue scissors to a size of about 1mm*1mm*1mm, digest the pulp tissue with a final concentration of 3mg / mL of Collagenase and 4mg / mL of Dispase, and act on a shaker at 37°C for 30 minute. After centrifugation at 1200rpm for 3 minutes at room temperature, discard the supernatant, transfer the digested tissue...

Embodiment 2

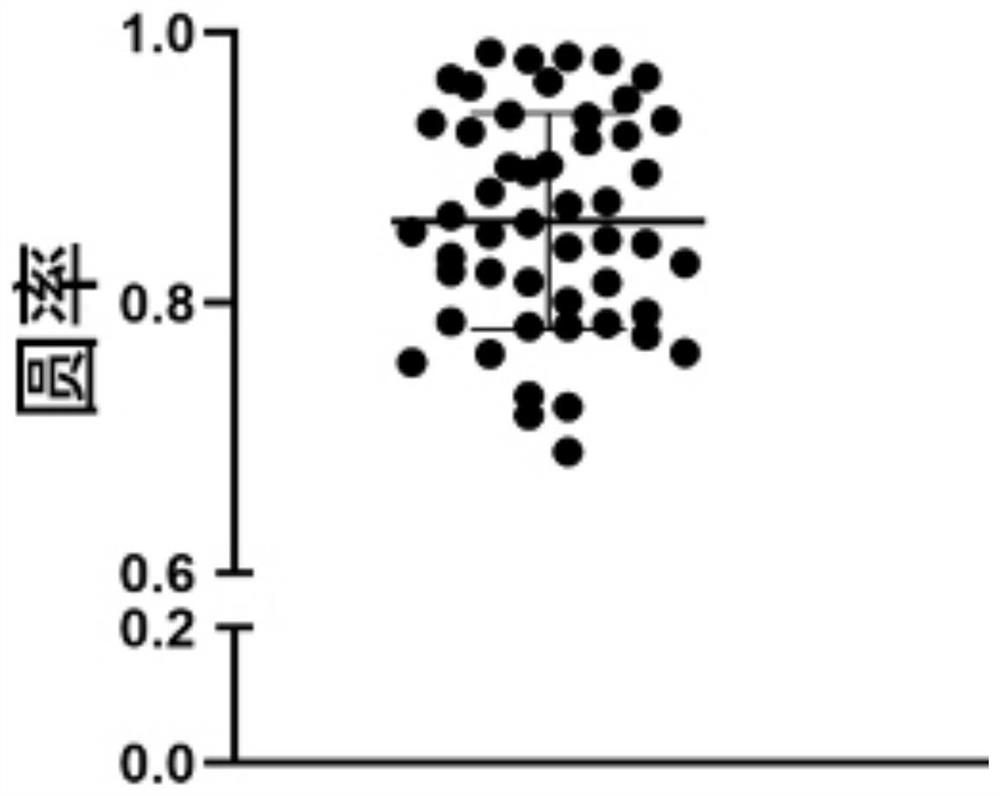

[0065] Example 2: Application of tissue engineered dental pulp based on digital optical processing and printing technology in nude mouse ectopic dental pulp regeneration model

[0066]Select the GelMA hydrogel microspheres loaded with dental pulp mesenchymal stem cells prepared in Example 1, and use a 20G (inner diameter of 620 μm, flat head) injection needle to inject the 3D-printed micropolymers with cells into the root canal of the dentin fragment, The root canal opening was covered with gelatin sponge (Microsphere group), and the prepared graft complexes were placed horizontally in a twelve-well plate, and ordinary complete medium (Gibco, USA) (containing double antibodies) was added at 37°C, 5% CO 2 After incubating in the environment for one day (standstill), the graft complexes of the printed microcarrier (Microsphere) group were buried subcutaneously in a nude mouse under general anesthesia. After the nude mice were fed for 8 weeks, the transplanted complex was taken o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com