Lithium ion battery negative electrode material and preparation method thereof

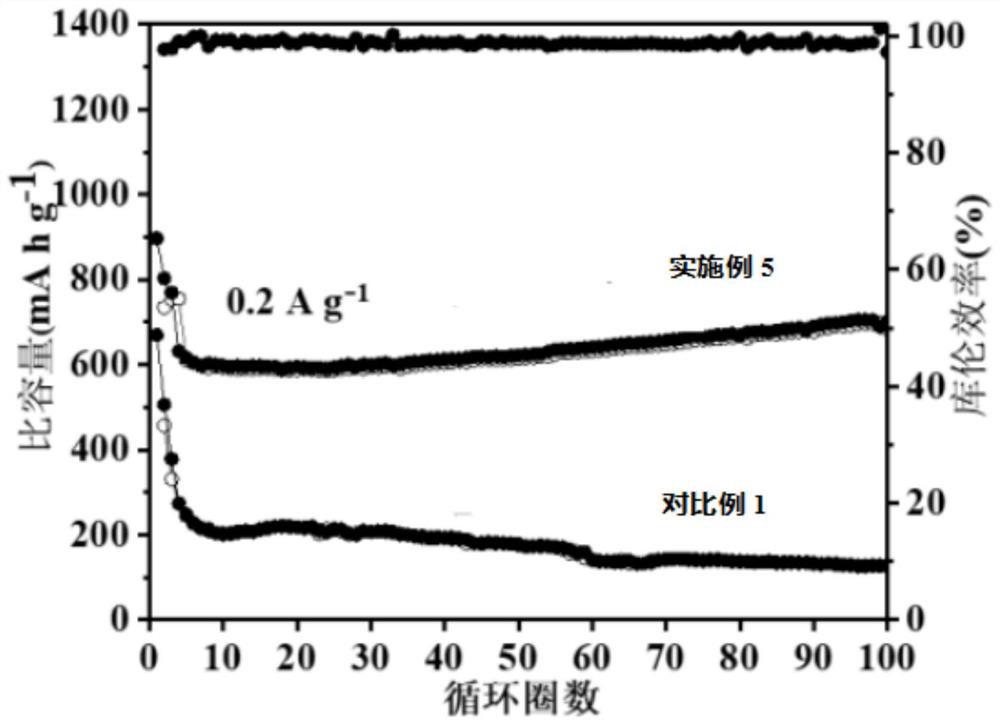

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. Membrane breakage and other problems, to achieve the effect of suppressing expansion, increasing the contact area, and simplifying the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A lithium ion battery anode material preparation method, including the steps of:

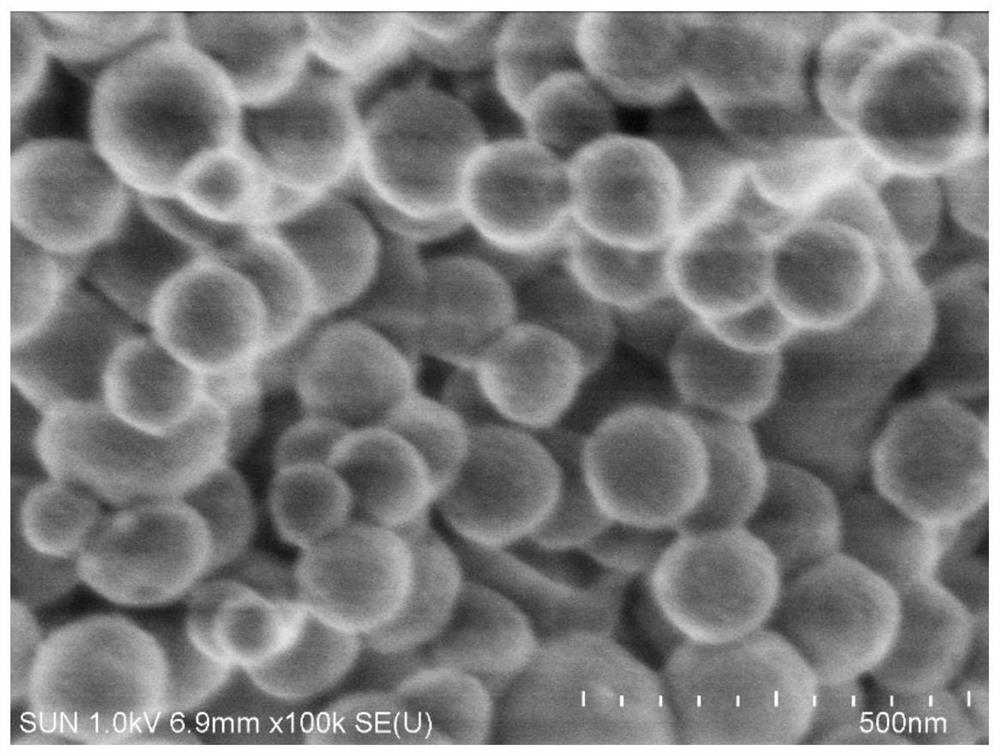

[0022] (1) 1 g of the block copolymer F127, 1.5 g of a dopamine is dissolved in 50 mL of deionized water and 50 mL of ethanol, and the stirring is continuously stirred at room temperature to become a colorless clarified solution, and 2 ml1 is added to the solution. 3,5-trimethylbenzene, adding ammonia water to adjusting pH of 8, continuous reactions for 4 h, centrifugation, centrifugation, centrifugation with water and ethanol 5 times, last at 60 ° C vacuum ovens for 12 h, resulting in polybatamine nano Microspheres.

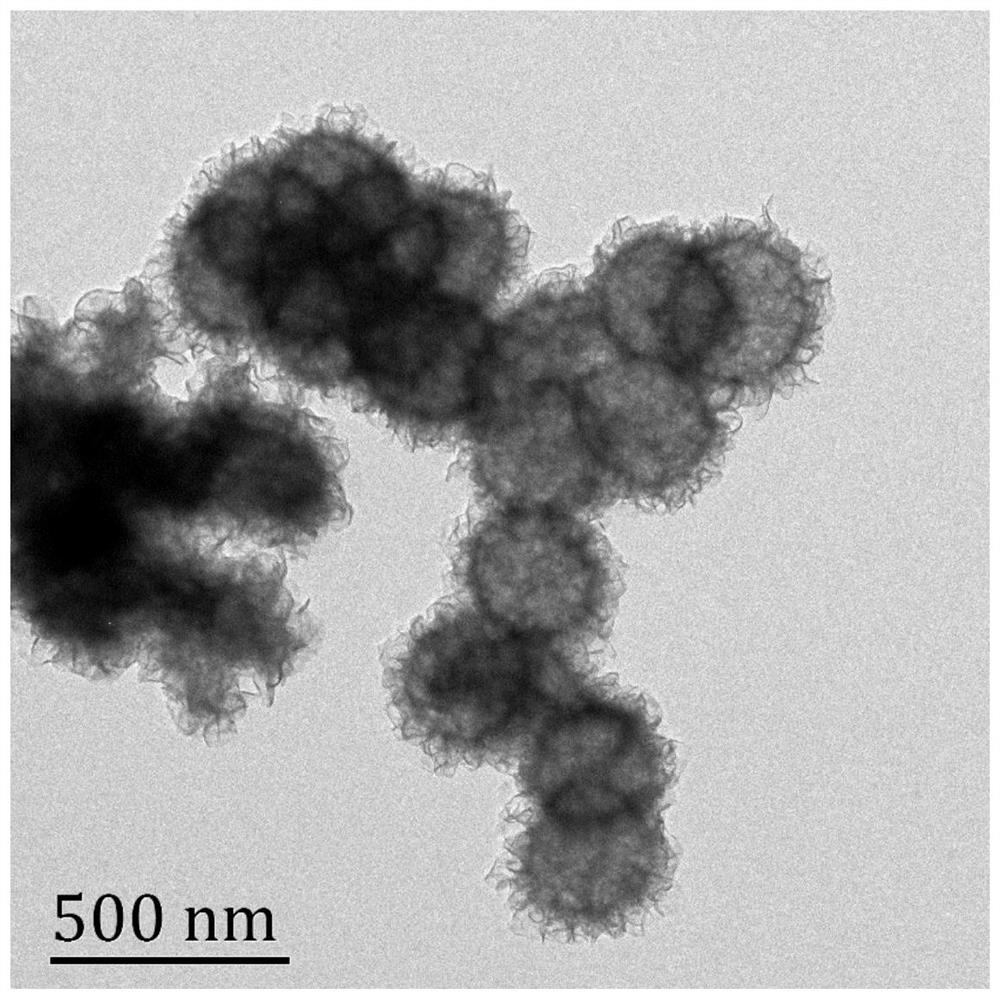

[0023] (2) 50 mg of the resulting polyopaline nanopospheres were dispersed in a dispersion of 30 ml of deionized water and 30 ml of ethanol, then 200 mg of sodium molybdate and 200 mg of thiourea were mixed to uniformly gave a mixed liquid, then transfer the mixture to In the 100 ml tetrafluoroethylene lined stainless steel autoclave, the black product was collected at 200 ° C,...

Embodiment 2

[0028] (1) 1 g of the block copolymer F127, 1.5 g of a dopamine is dissolved in 50 mL of deionized water and 50 mL of ethanol, and the stirring is continuously stirred at room temperature to become a colorless clarified solution, and 2 ml1 is added to the solution. 3,5-trimethylbenzene, the addition of ammonia water regulates the pH of 8. After the reaction is reacted for 4 h, the black product was centrifuged, washed with water and ethanol multiple centrifugation 3-5 times, and finally dried in a vacuum oven at 60 ° C. Get polybatamine nano microspheres.

[0029](2) 50 mg of the resulting polyopaline nanopospheres were dispersed in a dispersion of 30 ml of deionized water and 30 ml of ethanol, then 200 mg of sodium molybdate and 200 mg of thiourea were mixed to uniformly gave a mixed liquid, then transfer the mixture to In the 100 ml tetrafluoroethylene lined stainless steel autoclave, the black product was collected at 200 ° C, and the black product was centrifuged, washed with ...

Embodiment 3

[0032] (1) 1 g of the block copolymer F127, 1.5 g of a dopamine is dissolved in 50 mL of deionized water and 50 mL of ethanol, and the stirring is continuously stirred at room temperature to become a colorless clarified solution, and 2 ml1 is added to the solution. 3,5-trimethylbenzene, the addition of ammonia water regulates the pH of 8. After the reaction is reacted for 4 h, the black product was centrifuged, washed with water and ethanol multiple centrifugation 3-5 times, and finally dried in a vacuum oven at 60 ° C. Get polybatamine nano microspheres.

[0033] (2) 50 mg of the resulting polyopaline nanopospheres were dispersed in a dispersion of 30 ml of deionized water and 30 ml of ethanol, then 200 mg of sodium molybdate and 200 mg of thiourea were mixed to uniformly gave a mixed liquid, then transfer the mixture to In the 100 ml tetrafluoroethylene lined stainless steel autoclave, the black product was collected at 200 ° C, and the black product was centrifuged, washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com