Odor treatment system for recycling organic wastes

A technology of organic waste and treatment system, which is applied in the field of non-destructive testing, can solve the problems that it is difficult to deal with the scene of large flow of odorous gas, the deodorization process is not complete, and the efficiency of odor treatment is low, so as to achieve high environmental protection benefits and ecological value, deodorization effect is thorough, and the effect of saving waste gas treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

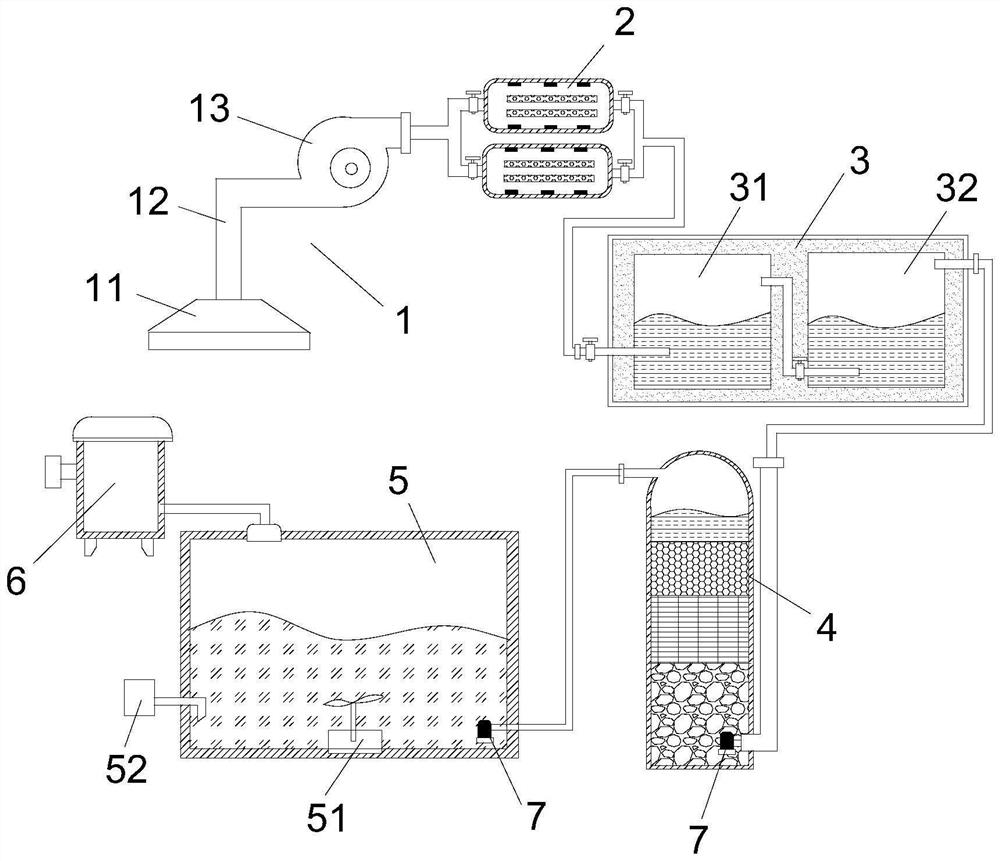

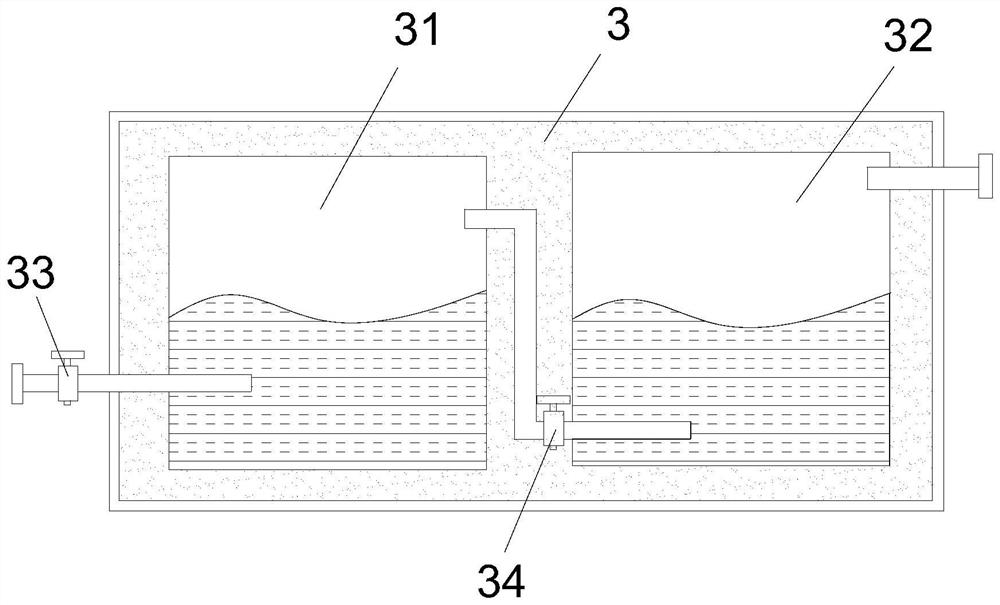

[0038]This embodiment provides an odor treatment system for organic waste resource utilization for harmimaging the odor gas generated by the organic waste composting process. like figure 1 As shown, the odor treatment system includes: a gas collecting mechanism 1, at least two ultraviolet photolysis purifier 2, a water washing pool 3, a suction position 4, a biological digestion 5, a sterilization device 6, and a controller 100.

[0039] Among them, the gas collecting mechanism 1 is used to collect the odor gas to be treated, and the gas is discharged into the rear segment; the gas collecting mechanism 1 includes a gauge 11, a fan 13, and a exhaust pipe 12.

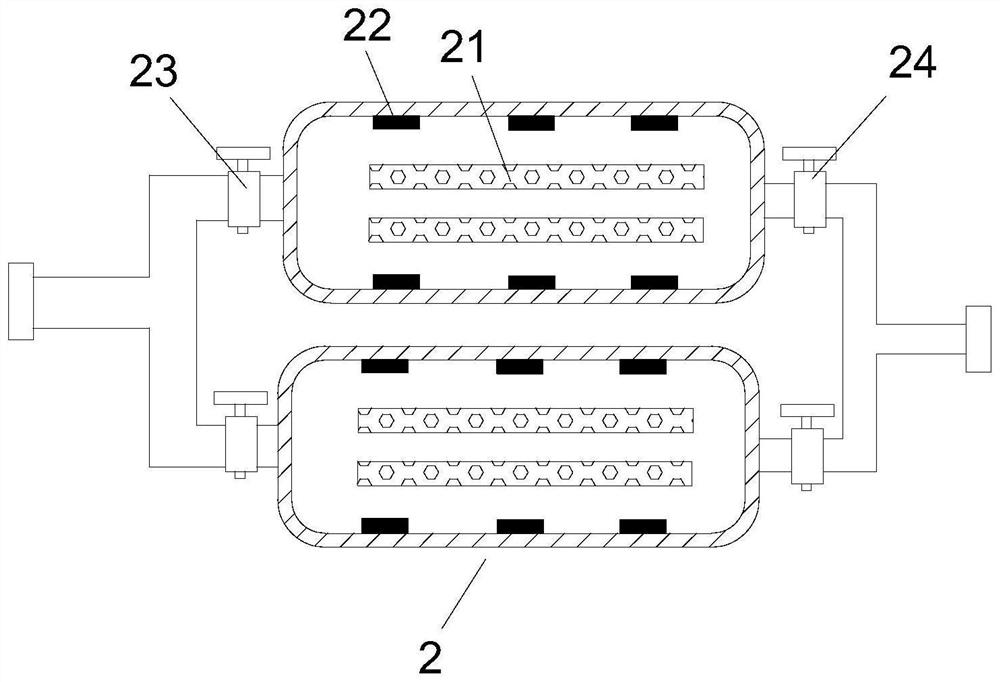

[0040] like figure 2 As shown, two ultraviolet photolysis purifiers 2 are arranged in parallel, and the gas collecting the gas collecting mechanism 1 is discharged into the processing chamber of the ultraviolet photolymer purifier 2. The catalyst 22 and the ultraviolet lamp 21 are provided in the ultraviolet photodegenerator ...

Embodiment 2

[0064] This embodiment provides a biological treatment process for chicken manure resource utilization, which is used in an odor treatment system for treating a chicken manure fermentation process using the organic waste resource utilization of Example 1. Produced odor, such as Image 6 As shown, the biological treatment process includes the following steps:

[0065] (1) Get the odor gas generated during the fermentation of the chicken manure.

[0066] (2) The acquired odor gas is passed into an ultraviolet photolymer purifier to complete a circulation process of a photocatalytic cracking process.

[0067] In this embodiment, the ultraviolet photolysis catalyst is used to disperse the nano-gold particles and nano-titanium dioxide as a catalyst dispersed in a molecular sieve carrier, and an ultraviolet ray is irradiated around the catalyst; a single photocatalytic cracking cycle is 7-8 min. In the ultraviolet photolymer purifier, the mass fraction of nanoplatin particles in the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com