Coating stent and preparation method thereof

A coating and inner layer technology applied in the field of medical devices to achieve the effects of no pollution to the environment, promotion of cell regeneration, and rapid endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

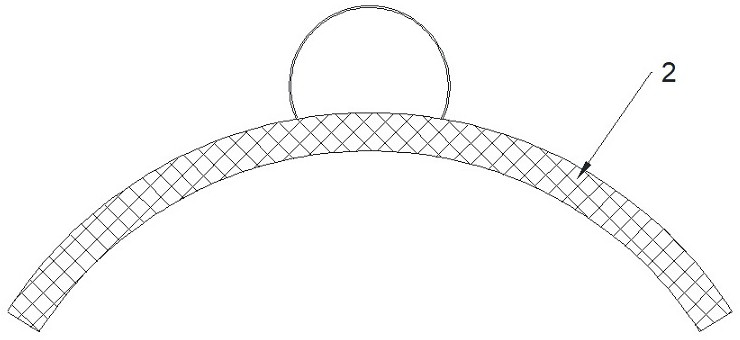

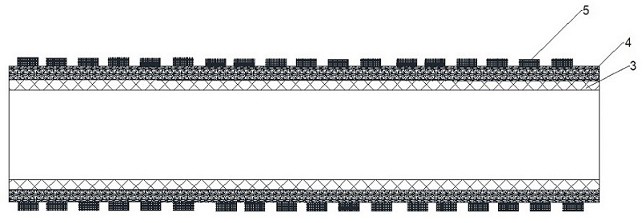

[0021] Such as figure 1 , 2 As shown in and 3, the coated stent of the patent of the present invention has a network structure, and the components of the network structure are composed of a three-layer structure, the inner layer is a stent layer, the middle layer is an anticoagulant modified layer, and the outermost layer is a nano-short Peptide coating; the inner layer of the stent network structure is composed of metal or polymer wires with a diameter of 0.01mm; the diameter of the coated stent is 3.0mm.

[0022] Such as image 3 , 4 As shown, the coated stent of the patent of the present invention is composed of three layers, the middle layer is an anticoagulant modified layer, and the anticoagulant modified layer is heparin, polyethylene glycol, phosphorylcholine, hydroxyl A mixture of one or more of ethyl cellulose, chitosan and its derivatives, and albumin; the thickness of the anticoagulant modified layer is 10nm. The nano-short peptide coating is a mixture of one o...

Embodiment 2

[0026] For example figure 1 The coated stent shown is prepared by the following process: the stent network structure is woven by a braiding machine; first, the processed stent network structure is subjected to oxygen plasma glow discharge treatment: the discharge power is 100W, and the treatment time is 30min. The oxygen flow rate is 500ml / min; the oxygen-treated scaffold is reacted with dicarboxylic acid polyethylene glycol; after the reaction is completed, continue to use N-hydroxysuccinimide and carbodiimide hydrochloride for carboxyl activation treatment: Then, the activated stent was modified by plasma deposition of anticoagulant phosphorylcholine: the plasma deposition temperature was 70° C., the glow discharge deposition time was 45 min, and the discharge power was 300 W. Finally, continue to spray the short peptide RGD intermittently and discontinuously on the surface-modified anticoagulant modified layer, so that the short peptide RGD reacts with part of the anticoagu...

Embodiment 3

[0028] For example figure 1 The coated stent shown is prepared by the following process: the stent network structure is cut from nickel-titanium tubes; first, the processed stent network structure is subjected to oxygen plasma glow discharge treatment: the discharge power is 20W, and the treatment time is 30min, the oxygen flow rate is 100ml / min; react the stent after oxygen treatment with polyacrylic acid; The final stent was modified by plasma deposition of anticoagulant heparin: the plasma deposition temperature was 105° C., the glow discharge deposition time was 20 min, and the discharge power was 200 W. Finally, continue to spray the short peptide RADA-16 intermittently and discontinuously on the surface-modified anti-coagulant modified layer, so that the short peptide RADA-16 reacts with part of the anti-coagulant coating by using a covalent bond.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com